-

×

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29 -

×

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46 -

×

3M 36866, Dirt Trap Wall Material Applicator, 36866, 1 per case, 7000045517

1 × $1,661.06

3M 36866, Dirt Trap Wall Material Applicator, 36866, 1 per case, 7000045517

1 × $1,661.06 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00 -

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25 -

×

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

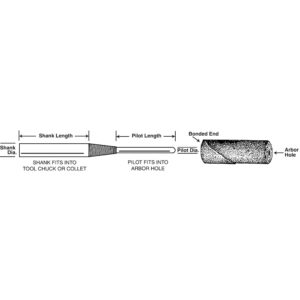

Standard Abrasives 717078, Cartridge Roll Mandrel, 3/32 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-2E, 7000121813

5 × $4.88

Standard Abrasives 717078, Cartridge Roll Mandrel, 3/32 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-2E, 7000121813

5 × $4.88 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00 -

×

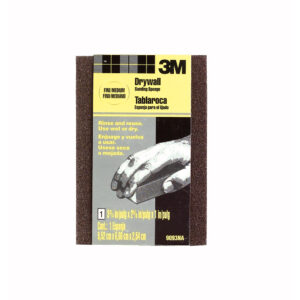

3M 09093, Drywall Sanding Sponge 9093DC, Dual Grit Block, 3-3/4 in x 2-5/8 in x 1 in, Fine/Medium, 7100180421

20 × $1.97

3M 09093, Drywall Sanding Sponge 9093DC, Dual Grit Block, 3-3/4 in x 2-5/8 in x 1 in, Fine/Medium, 7100180421

20 × $1.97 -

×

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

3M 36866, Surface Protection Material Wall Applicator 36866, 28 in, 1/Case, 7100226306

1 × $1,775.62

3M 36866, Surface Protection Material Wall Applicator 36866, 28 in, 1/Case, 7100226306

1 × $1,775.62 -

×

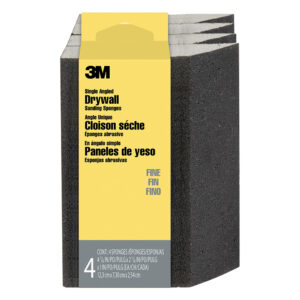

3M 91004, Drywall Sanding Sponge CP-042-4PK, Single Angle, 4-7/8 in x 2-7/8 in x 1 in, Fine, 7100111452, 4/pack

6 × $5.94

3M 91004, Drywall Sanding Sponge CP-042-4PK, Single Angle, 4-7/8 in x 2-7/8 in x 1 in, Fine, 7100111452, 4/pack

6 × $5.94 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

Standard Abrasives 78511, Ceramic Pro Type 27 Flap Disc, 645104, 4-1/2 in x 5/8-11 80 Y-weight, 7010331461

$9.26

Factory Stock, 7-10 Day Leadtime

Built for rapid stock removal, our Standard Abrasives Ceramic Pro Flap Disc is our highest performing flap disc. It delivers an exceptionally fast cut and runs cool on stainless steel, high nickel alloys and aluminum. Tough overlapping poly-cotton flaps won’t fray with edgework, maintain a sharp cut as the flaps wear away, and leave a smooth finish.

Achieves Aggressive Cut with Smooth Finish, Resists Gouging

A workhorse for metal fabrication, the Standard Abrasives™ Ceramic Pro Flap Disc achieves fast, aggressive stock removal without compromising finish. It is ideal for a wide range of low to medium-high pressure applications, especially in paint prep and stainless steel fabrication where finish and gouge resistance are important. A grinding aid on the disc reduces grinding temperatures for best results and extended disc life in operations on stainless steel and steel alloys.

Outcuts and Outlasts Grinding Wheels and Fiber Discs

The overlapping layers of coated abrasive cloth flaps make this disc flexible, long lasting, sharp cutting, and a great choice for one step grinding and blending. In many instances it can replace grinding wheels and fiber discs, making it an advantageous addition to machine shops and body shops.

Compared to a grinding wheel, a flap disc cuts cooler, works faster, and is more user-friendly. The phenolic resin disc plate cushions the disc and reduces disc vibration, producing optimal finish and greater operator comfort. Moreover, the flexibility of the flaps also reduces vibration and produces smoother results, which means the disc is easier to control and causes less operator fatigue.

A flap disc will outlast a fiber disc while still providing an aggressive cut, so you can count on replacing it less often, which saves time and reduces consumables. It produces a smoother, more consistent finish, and won’t curl up in storage as fiber discs sometimes do. Choose one grade coarser than the fiber disc you would typically use for your application for comparable results.

Disc Workhorse Offers Great Versatility

When faster output is the bottom line, you will appreciate the value of our Standard Abrasives™ Ceramic Pro Flap Disc. Use it to:

- Make quick work of rust or other contaminants

- Rapidly smooth out welds, beads and burrs

- Knock down sharp edges

- Perform minor material shaping

- Remove cutting torch slag from steel plates

- Strip paint off of metal

- Level auto body filler

- Touch up welds

- Remove slap

A flap disc may also be used for paint prep on wood, although it won’t leave the same smooth finish it achieves on metal.

Choosing a Flap Disc

We engineered Standard Abrasives™ Flap Discs with the industrial operator in mind ? they deliver exceptional cut and long life. Variations in mineral type, backing and disc shape enable efficient abrasive solutions. By pairing the right flap disc with your unique application you ensure peak performance and market-leading value. We offer discs with five designations (each sold separately):

- Zirconia GP: Ideal for low pressure grinding on flat surfaces such as weld touchups and surface prep; cotton backing

- Zirconia AP: Versatile disc performs well when you need one disc for a variety of applications; poly-cotton backing

- Zirconia HP: More durable backing supports high pressure grinding such as beveling, deburring and edge chamfering ; grinding aid for stainless and high nickel alloys; polyester backing

- Ceramic: Faster cut than Zirconia on high-pressure applications; cool cutting action reduces loading risk and discoloration; grinding aid for stainless and high nickel alloys; cotton backing

- Ceramic Pro: Fastest cutting; grinding aid, ideal for stainless steel and high tensile alloys; poly-cotton backing

Designed for use on a right angle grinder, flap discs have a Type 27 or Type 29 profile.

- Type 27 Flat: Flaps are flush with a flat surface and ideal for generating a smooth finish on flat areas or outside edges

- Type 29 Conical: Flaps are angled to provide more aggressive cutting action ideal for stock removal and faster results on both edge work, flats and contours

Quality Solutions for Industrial Operations

The Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non-woven abrasive lines.