-

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

4 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

4 × $722.00 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64 -

×

Dynabrade 94821 - 3/8" ID, 10' Long Air Hose Assembly, Female/ Male Fitting Ends Included

1 × $65.58

Dynabrade 94821 - 3/8" ID, 10' Long Air Hose Assembly, Female/ Male Fitting Ends Included

1 × $65.58 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.06

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.06 -

×

Dynabrade 11282 Contact Wheel Ass'y, 3/4" Dia. x 5/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $42.43

Dynabrade 11282 Contact Wheel Ass'y, 3/4" Dia. x 5/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $42.43 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $1,721.00 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,520.00 -

×

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

4 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

4 × $28,988.00 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

2 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

2 × $1,012.00 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

1000 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

1000 × $0.60 -

×

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

3 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

3 × $1,569.00 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

3 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

3 × $109.23 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,712.00 -

×

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Standard Abrasives 730174, Ceramic Side Wall Cartridge Roll, 3/4 in x 3 in x 1/4 in, 100, 7100102868

25 × $4.00

Standard Abrasives 730174, Ceramic Side Wall Cartridge Roll, 3/4 in x 3 in x 1/4 in, 100, 7100102868

25 × $4.00 -

×

Dynabrade 11072 Contact Wheel Ass'y, 7/16" Dia. x 1/8" W x 3/8" I.D., Crown Face, Brass

2 × $35.33

Dynabrade 11072 Contact Wheel Ass'y, 7/16" Dia. x 1/8" W x 3/8" I.D., Crown Face, Brass

2 × $35.33 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

2 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

2 × $1,679.00 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1000 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1000 × $0.60 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

2 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

2 × $1,245.00 -

×

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Dynabrade 94858 25' Max Flow 10mm I.D. Air Hose Assembly, Male (1/4") / Male (1/4") Fitting Ends Included

2 × $144.02

Dynabrade 94858 25' Max Flow 10mm I.D. Air Hose Assembly, Male (1/4") / Male (1/4") Fitting Ends Included

2 × $144.02 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

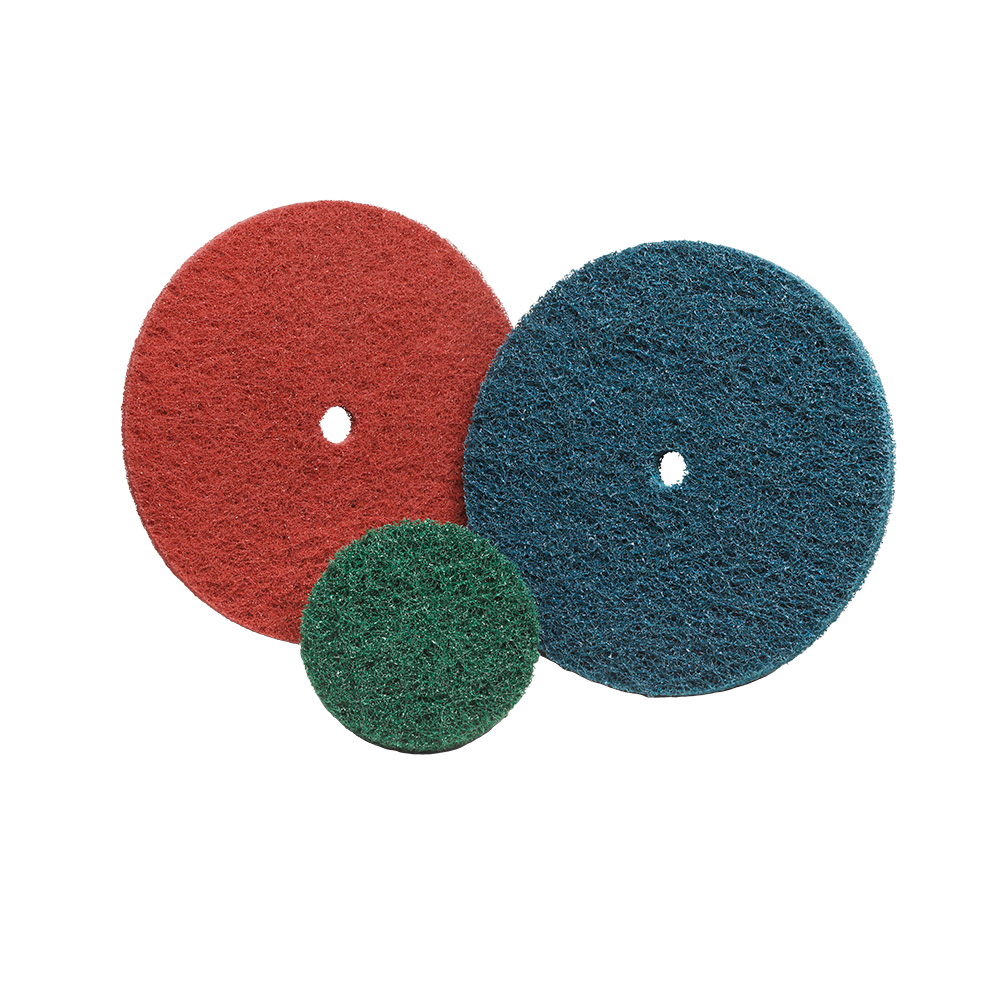

Standard Abrasives 860708, Buff and Blend HS Disc, 6 in x 1/2 in A VFN, 7000046751

$3.41

Factory Stock, 7-10 Day Leadtime

High Strength non-woven nylon material ensures that our Standard Abrasives Buff and Blend HS Disc maintains stiffness and won’t tear or fray when faced with challenging edgework or irregular surfaces. Within the Standard Abrasives Buff and Blend product line, the HS Disc offers the best performance for cleaning and light deburring while achieving a final finish or polished piece.

Three Grades Well-Suited for Deburring and Finishing Irregular-Shaped Parts

Among the four Standard Abrasives™ Buff and Blend materials, HS material is the most stiff, durable and aggressive. Given its strength and durability, our Standard Abrasives™ Buff and Blend HS Disc is a good match for irregular-shaped parts, such as pipe threads, the edges of molded glass containers, and non-ferrous die cast molded parts. It removes small, stubborn burrs and cuts sharp to produce a consistent finish. Non-woven construction makes the material responsive to contours and extrusions, so it is unlikely to gouge or mar the substrate while achieving an aggressive cut.

Aluminum oxide abrasive grain bonded to the nylon strands produces a uniform scratch pattern – perfect for satin or grain finishing. Use a Standard Abrasives™ Buff and Blend HS Disc for final finishing on brass, steel, bronze, pewter, and stainless steel, as well as plated plastics. If desired, discs may be ganged on a shaft to form a wheel for off-hand applications.

When a very fine high luster and decorative finish is desirable on pieces such as builders hardware, choose the HS Disc in MED or VFN grade. For applications that may require a faster cut or coarser finish, choose the CRS grade disc. The coarser scratch pattern of the CRS disc also makes it ideal for satin and grain finishing applications, as well as blending and cleaning surface imperfections.

HS Coarse Features and Applications

- Produces a uniform, coarse finish similar to Surface Conditioning material

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Durable enough to finish edges and welds

- Satin and grain finishing of metal surfaces

- Blending and cleaning surface imperfections

- Blending out tool marks

- Markets include stainless steel fabricators, plumbing fixtures, metal fabricators, door hardware, food equipment Manufacturers, builder’s hardware, aluminum extruded products, and aerospace

- Green

HS Medium Features and Applications

- Rigid, durable construction accomplishes edge breaking, deburring and finishing finish edges and welds

- Satin and grain finishing of metal surfaces

- Cleaning surface contamination

- Deburring and edge breaking

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Produces a clean finish, without irregular scratches and “sparkles”

- Markets include stainless steel fabricators, plumbing fixtures, door hardware, food equipment manufacturers, aluminum extruded products, aircraft engine manufacturers, orthopedic implants

- Blue

HS Very Fine Features and Applications

- Excels at light deburring and final finishing of small, irregular shaped parts

- Light edge breaking on machined or stamped parts

- Edge radiusing

- Deburring threaded parts

- Pre-finish of precious metals prior to polishing

- Markets include aerospace, aircraft equipment, foundries, machine builders, machine shops, and mold and die shops

- Maroon

- When your application calls for a lighter-duty disc or if the final finish isn’t as critical, we suggest our Standard Abrasives™ Buff and Blend GP or HP Disc. For off-hand and automated finishing processes, we recommend the loftier Buff and Blend HS-F Disc

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.