-

×

3M 31959, 6450J, M125, 1" X 30", Type C, Pattern 18 Diamond Belts, 7100052712

1 × $0.00

3M 31959, 6450J, M125, 1" X 30", Type C, Pattern 18 Diamond Belts, 7100052712

1 × $0.00 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 30u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 30u

12 × $7.60 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 71512, Cloth Belt 340D, 50 X-weight, 3 in x 18 in, Fabri-lok, Single-flex, 7010294780, 25 per case

25 × $3.12

3M 71512, Cloth Belt 340D, 50 X-weight, 3 in x 18 in, Fabri-lok, Single-flex, 7010294780, 25 per case

25 × $3.12 -

×

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

3M 47408, 663FC 1" X 30", 70u Diamond Trizact Belts, 7010509031

1 × $159.76

3M 47408, 663FC 1" X 30", 70u Diamond Trizact Belts, 7010509031

1 × $159.76 -

×

3M 49056, Polyurethane Adhesive Sealant 560, White, 310 mL Cartridge, 7000000945, 12/case

12 × $14.64

3M 49056, Polyurethane Adhesive Sealant 560, White, 310 mL Cartridge, 7000000945, 12/case

12 × $14.64 -

×

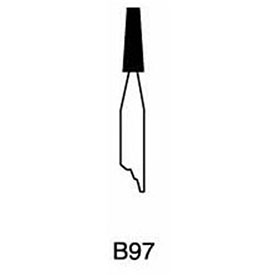

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22 -

×

3M 65022, Scotch-Brite Deburr and Finish Pro Unitized Wheel, DP-UW, 6C Medium+, 3 in x 3/4 in x 1/4 in, 7100053421

20 × $24.62

3M 65022, Scotch-Brite Deburr and Finish Pro Unitized Wheel, DP-UW, 6C Medium+, 3 in x 3/4 in x 1/4 in, 7100053421

20 × $24.62 -

×

3M 97841, Value Duct Tape 1900, Silver, 1.88 in x 60 yd, 5.8 mil, 7010375734

24 × $12.04

3M 97841, Value Duct Tape 1900, Silver, 1.88 in x 60 yd, 5.8 mil, 7010375734

24 × $12.04 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M 13185, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Coarse, 8 in x 2 in x 3 in, 7000120809

2 × $124.20

3M 13185, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Coarse, 8 in x 2 in x 3 in, 7000120809

2 × $124.20 -

×

3M 62819, Adhesive Sealant 760 UV, Gray, 290 mL Cartridge, 7100097767, 12/Case

12 × $19.85

3M 62819, Adhesive Sealant 760 UV, Gray, 290 mL Cartridge, 7100097767, 12/Case

12 × $19.85 -

×

3M 14343, Marine Adhesive Sealant 4000 UV, Black, 600 mL Sausage Pack, 7010309931, 12/Case

12 × $25.07

3M 14343, Marine Adhesive Sealant 4000 UV, Black, 600 mL Sausage Pack, 7010309931, 12/Case

12 × $25.07 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $1,925.99

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $1,925.99 -

×

3M™ 37018, Supplied Air Respirator Vortex Cooling Assembly V-100/37018(AAD), 70070799013, 1 EA/Case

1 × $397.07

3M™ 37018, Supplied Air Respirator Vortex Cooling Assembly V-100/37018(AAD), 70070799013, 1 EA/Case

1 × $397.07 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M 40544, VHB Tape LSE-060WF, White, 1/2 in x 36 yd, 0.6 mm, 18 rolls per case, 7100218845

$36.22

Factory Stock, 7-10 Day Leadtime

Dream, Design, Deliver with our 3M VHB Tape 5907. It is a black, 0.008 in (0.20 mm), modified acrylic adhesive with a very conformable, foam core. This tape can replace mechanical fasteners or liquid adhesives and is designed specifically for applications with thin bond lines. The fast and easy to use permanent bonding method provides high strength and long-term durability.