-

×

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 60052 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 35,000 RPM, 3/32" Collet

1 × $1,025.00

Dynabrade 60052 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 35,000 RPM, 3/32" Collet

1 × $1,025.00 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

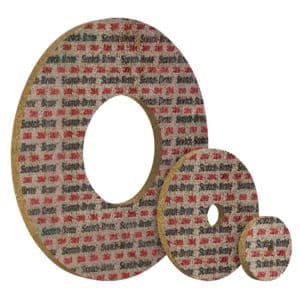

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M 51033, Roloc Disc 361F, 36 YF-weight, TSM, 3 in, Die RS300VM, 7000148150

200 × $1.50

3M 51033, Roloc Disc 361F, 36 YF-weight, TSM, 3 in, Die RS300VM, 7000148150

200 × $1.50 -

×

3M 94706, Cubitron ll Cloth Belt 947A, 1/2 in x 24 in, 60+ X-weight, 7010307699, 200 per case

200 × $2.63

3M 94706, Cubitron ll Cloth Belt 947A, 1/2 in x 24 in, 60+ X-weight, 7010307699, 200 per case

200 × $2.63 -

×

3M 76750, Roloc Disc 777F, 60 YF-weight, TS, 2 in, Die RS200P, 7010299188

200 × $1.12

3M 76750, Roloc Disc 777F, 60 YF-weight, TS, 2 in, Die RS200P, 7010299188

200 × $1.12 -

×

3M 06219, Stikit Film Disc Roll 360L, P400, 5 in x NH, Die 500X, 7000144139, 125 discs per roll

4 × $60.19

3M 06219, Stikit Film Disc Roll 360L, P400, 5 in x NH, Die 500X, 7000144139, 125 discs per roll

4 × $60.19 -

×

3M 04240, Semi-Rigid Plastic Repair, 04240, 200 mL Cartridge, 7000046371

6 × $63.58

3M 04240, Semi-Rigid Plastic Repair, 04240, 200 mL Cartridge, 7000046371

6 × $63.58 -

×

Dynabrade 51708 .1 hp Straight-Line Pencil Grinder, 35,000 RPM, 3/32" Collet

2 × $558.00

Dynabrade 51708 .1 hp Straight-Line Pencil Grinder, 35,000 RPM, 3/32" Collet

2 × $558.00 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

3M 88905, PSA Cloth Disc 348D, 40 X-weight, 12 in x NH, Die 1200B, 7010294665

10 × $8.41

3M 88905, PSA Cloth Disc 348D, 40 X-weight, 12 in x NH, Die 1200B, 7010294665

10 × $8.41 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60 -

×

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40 -

×

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00 -

×

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 82614, Hot Melt Adhesive 3762 PG, Tan, 1 in x 3 in, 7000046513, 22 LBS/Case

$16.71

Factory Stock, 7-10 Day Leadtime, Priced Per LB

3M Hot Melt Adhesive 3762 is a 100% solids, fast-setting hot melt adhesive designed for packaging and shipping applications. It is ideal for bonding corrugated fiberboard cartons, wood, particle board, chipboard and foam. The recommended application temperature range is 350-385?F (177-196?C)

Aggressive Hot Tack Rapidly Achieves Handling Strength

3M™ Hot Melt Adhesive 3762 is 100% solids, thermoplastic resin formulated to grab and seal quickly to meet the demands of high-volume production settings such as packing, woodworking and assembly. These features increase the speed of carton closures and provide adhesion to wood, paperboard, corrugated and other fibrous substrates. It provides strong shear strength, which means your packages stay sealed and components stay bonded under most conditions. A 25 second open time, along a 1/8″ bead, is sufficient for positioning and adjusting for fit and supports high-tempo productivity for packaging, woodworking, and applications that involve fibrous materials. The low viscosity prevents stringing even at fast production speeds. Recommended application temperature range: 350-385°F (177-196°C).

Recommended Applications

- General packaging

- Securing wood supports and reinforcements

- Repacking chipboard

- Point-of-purchase displays

- Trade exhibits

- Bonding waxed surfaces

Understanding Hot Melt Adhesives

Hot melt adhesives, also known as glue sticks, are liquefied thermoplastic adhesives available in both low and high-temperature versions. Low temperature hot melt adhesives are applied at 250F/121C temperatures, which makes them ideal for bonding electronics, plastics, cloth and other heat sensitive materials. High temperature hot melt adhesives are applied at 380F/193C and produce a stronger bond than the low temperature hot melts.

Melted adhesive is extruded through a nozzle using a 3M™ Hot Melt Applicator by either pneumatic pressure, a mechanical trigger mechanism, or with pressure applied directly on the stick. Different nozzles can be used to apply thin, wide strips or narrow, thicker beads. Hot melt adhesive generally sets quickly, ranging from a few seconds to a few minutes, depending on the adhesive formulation.

Bringing Better Ideas to the Surface through Science and Innovation

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, our technologies help customers like you deliver competitive products to the market faster and more efficiently.