-

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.70 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

2 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

2 × $274.26 -

×

3M 19808, Nitrile High Performance Plastic Adhesive 1099, Tan, 5 Oz Tube, 7000000796, 36/case

36 × $21.72

3M 19808, Nitrile High Performance Plastic Adhesive 1099, Tan, 5 Oz Tube, 7000000796, 36/case

36 × $21.72 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00 -

×

3M 16159, PTFE Glass Cloth Tape 5453, Brown, 3/4 in x 36 yd, 8.2 mil, 7000050132

12 × $193.37

3M 16159, PTFE Glass Cloth Tape 5453, Brown, 3/4 in x 36 yd, 8.2 mil, 7000050132

12 × $193.37 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M 37301, Versaflo Painter`s Hood Assembly with Inner Shroud & Premium Head Suspension S-757, 7000052768, 1 EA/Case

1 × $107.31

3M 37301, Versaflo Painter`s Hood Assembly with Inner Shroud & Premium Head Suspension S-757, 7000052768, 1 EA/Case

1 × $107.31 -

×

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55 -

×

Marson Kwikee 30200, Disposable Plastic Seat covers, 125 per pack, 7000125073

1 × $70.95

Marson Kwikee 30200, Disposable Plastic Seat covers, 125 per pack, 7000125073

1 × $70.95 -

×

3M 77157 Scotch-Brite Durable Flex Belt, 77157, 1/2 in x 18 in, A MED, Trial Pack, 7010365702

10 × $19.33

3M 77157 Scotch-Brite Durable Flex Belt, 77157, 1/2 in x 18 in, A MED, Trial Pack, 7010365702

10 × $19.33 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

3M 86398, Scotch-Weld Multi-Material Composite Urethane Adhesive DP6310NS,Green, 400 mL Duo-Pak, 7100109830, 6/case

6 × $74.39

3M 86398, Scotch-Weld Multi-Material Composite Urethane Adhesive DP6310NS,Green, 400 mL Duo-Pak, 7100109830, 6/case

6 × $74.39 -

×

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.14

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.14 -

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

80 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

80 × $11.50 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

Dynabrade 51706 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $558.00

Dynabrade 51706 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $558.00 -

×

3M 20279, Disc Pad Holder 947TH, 7 in x 1 in x 5/8-11 Internal Black T Hook, 7000118602

1 × $47.80

3M 20279, Disc Pad Holder 947TH, 7 in x 1 in x 5/8-11 Internal Black T Hook, 7000118602

1 × $47.80 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

2 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

2 × $1,012.00 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

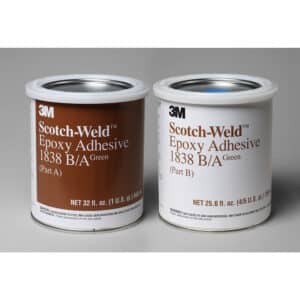

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

3M 20105, Scotch-Weld Epoxy Adhesive 1751, Gray, Part B/A, 1 Gallon Kit, 7000046339, 2/case

2 × $916.63

3M 20105, Scotch-Weld Epoxy Adhesive 1751, Gray, Part B/A, 1 Gallon Kit, 7000046339, 2/case

2 × $916.63 -

×

3M 81734, Disc Pad Face Plate Ribbed, 5 in Medium Gray, 7000120516

1 × $21.83

3M 81734, Disc Pad Face Plate Ribbed, 5 in Medium Gray, 7000120516

1 × $21.83 -

×

3M 20856, Scotch-Weld Epoxy Adhesive 2216, Translucent, Part B/A, 1 Gallon Kit, 7000046480, 2/case

2 × $948.90

3M 20856, Scotch-Weld Epoxy Adhesive 2216, Translucent, Part B/A, 1 Gallon Kit, 7000046480, 2/case

2 × $948.90 -

×

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 17098, Hood Assembly with Sealed Seams Inner Shroud and Premium Head Suspension S-857, 7000002350, 1 EA/Case

1 × $185.27

3M 17098, Hood Assembly with Sealed Seams Inner Shroud and Premium Head Suspension S-857, 7000002350, 1 EA/Case

1 × $185.27 -

×

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

Standard Abrasives 882115, A/O Unitized Wheel, 821, 2 in x 1/2 in x 1/4 in, 7010310376

$10.27

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Aluminum Oxide 800 Series Unitized Wheel is a hard density wheel designed with extra tough edge durability, making it a good match for heavy-duty edge deburring and stainless steel polishing applications.

Hard Density Abrasive Wheel Removes Challenging Burrs with Precision and Imparts a Fine Polish

Our Standard Abrasives Aluminum Oxide 800 Series Unitized Wheel is offered in two grades of aluminum oxide (A/O) mineral: coarse or medium. The hardness of this wheel places it on the upper end of the spectrum of aggressiveness among Standard Abrasives Unitized Wheels. Given the coarseness of the mineral and the greater density, this wheel is able to withstand high-pressure applications and cut aggressively, making it well-suited for deburring and polishing applications.

Use our Standard Abrasives 800 Series Unitized Wheel for deburring stainless steel pipe thread, wire edges from surgical instruments, stainless steel sinks, tanks and other equipment for the food service industry. It is a prime choice for deburring gears and aircraft wing spars, and breaking edges on aluminum extrusions. When it comes to polishing, trust the 800 Series A/O Unitized Wheel to effectively polish stainless steel rule dies, welds on stainless steel sinks, machined surfaces, hand tools and round tubing.

Compatible with a Variety of Tools

Unitized wheels are typically used on a die grinder. A benefit of unitized wheels is that they are bi-directional and can be mounted on a tool or pedestal grinder without regard to the direction of the spindle rotation. This means the Standard Abrasives Unitized Wheel can be used with a variety of tools, and regardless of which way the workpiece is fed through the machine, the wheel will be able to respond, giving operators more flexibility. The stiffness of the unitized construction enables operators to use thinner wheels to access awkward angles with grinding tools.

Series 800 wheels comes in a range of diameters from 1-6″ and requires a unitized wheel mandrel (sold separately) for attachment to the tool. Quick change wheels are also available (sold separately).

Non-Woven Unitized Construction Offers a Step Up in Density and Durability for Stubborn Surfaces

Standard Abrasives Unitized Wheels are a great match for tough deburring, cleaning, blending and finishing applications. They come in a broad range of densities and grades to suit different metals, the degree of aggressiveness required, shape of the part, and desired finish. Although used for some of the same tasks as Standard Abrasives Buff and Blend products, they are designed with a far stronger and denser construction to support more aggressive applications and accomplish material removal more rapidly. Even though unitized wheels are much stiffer products, the non-woven nylon fibers of the wheel maintain the advantage of responding to surface irregularities while preserving the geometry of the piece, and produce a consistent finish.

Unitized wheels are created by starting with layers of open web material that combines non-woven fiber strands and abrasive mineral with a tough resin bond. These layers of web are then cured and compressed together. By fusing layers of open web, the abrasive gains more toughness and durability, so it can withstand repeated wear.

Ultimately, the wheel’s durability is what makes it such a good match for edges. Regardless of the diameter or thickness of the wheel, it maintains its structural integrity to remain a stiff and long-lasting abrasive even under high pressure. Additionally, as the layers wear, the wheel can be dressed to maintain its shape.

Load-Resistance Boosts Life and Performance

Standard Abrasives Unitized Wheels are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives Non-Woven Products

Standard Abrasives Unitized Wheels offer many benefits for heavy-duty jobs. For all the aforementioned reasons, Standard Abrasives Unitized Wheels invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput.