-

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

2 × $1,598.86

Dynabrade 14360 Pneumatic Pipe Belt Finisher

2 × $1,598.86 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44 -

×

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94 -

×

Dynabrade 53249 9" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,531.52

Dynabrade 53249 9" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,531.52 -

×

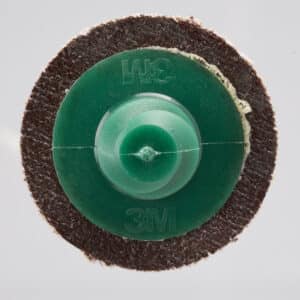

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18 -

×

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53 -

×

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41 -

×

Dynabrade 64002 SuperFinisher, 230 Volts (AC), 1 Phase, 50 Hz

1 × $14,467.64

Dynabrade 64002 SuperFinisher, 230 Volts (AC), 1 Phase, 50 Hz

1 × $14,467.64 -

×

Dynabrade 79170 1" W x 30" L 60 Grit Ceramic DynaCut Belt, 50/pack

50 × $6.50

Dynabrade 79170 1" W x 30" L 60 Grit Ceramic DynaCut Belt, 50/pack

50 × $6.50 -

×

Dynabrade 52900 Take-About Sander Abrasive Belt Tool, Central Vacuum

1 × $3,684.03

Dynabrade 52900 Take-About Sander Abrasive Belt Tool, Central Vacuum

1 × $3,684.03 -

×

Dynabrade 79139 1/8" W x 24" L 60 Grit Ceramic DynaCut Belts, 50/pack

50 × $2.18

Dynabrade 79139 1/8" W x 24" L 60 Grit Ceramic DynaCut Belts, 50/pack

50 × $2.18 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

Dynabrade 95541 Grease Gun

1 × $31.98

Dynabrade 95541 Grease Gun

1 × $31.98 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.18

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.18

3M 33230, Scotch-Brite SF Finishing and Deburring Wheel, SF-WL, 11S Fine, 8 in x 1 in x 3 in, 7010365350

$129.11

Factory Stock, 7-10 Day Leadtime

Our Scotch-Brite SF Finishing and Deburring Wheel is a convolute wheel that balances deburring with finishing – removing stubborn burrs while still delivering a fine finish.

Convolute Construction

To construct our Scotch-Brite™ SF Finishing and Deburring Wheel we wrap non-woven abrasive web around a fiberglass core. With convolute wheels the surface of the web becomes the cutting tool. Moreover, the wheels are one directional, which is indicated by an arrow on the side of the wheel and arrows printed on the core. Following the direction indicated on the wheel is imperative — both for optimal wheel performance and operator safety. Considering all variations of Scotch-Brite™ convolute wheels, the SF wheel falls in the middle in terms of aggressiveness and durability. When compared to other Scotch-Brite™ materials, it could be considered medium-density. Yet, this is one of the characteristics that makes it perfect for balancing deburring with finishing. It is aggressive enough to tackle flash and imperfections, while soft enough to not severely gouge the part.

Key Ingredients: Silicon Carbide, Resin and Nylon

The abrasive material in the Scotch-Brite™ SF Finishing and Deburring Wheel is a combination of non-woven nylon fibers and silicon carbide mineral. To combine these elements, we use a resin bond. The resin bond breaks down gradually while the wheel wears, helping with overall heat resistance. It is an excellent option when finish is critical on deburring applications. Silicon carbide mineral is very hard and fractures easily, resulting in freshly exposed sharp edges that cut extra fast and produce a smooth, professional-looking finish. While it wears faster than aluminum oxide, it produces a superior finish.

Key Strike a Balance

Some common applications include general deburring of machined and formed parts, deburring and finishing turbine blades, gun barrel polishing, golf club finishing and medical component deburring and finishing. Altogether, this wheel is uniquely equipped to help operators remove flash and imperfections while achieving a refined and polished finish.