-

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

60 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

60 × $12.65 -

×

3M 16579, Accuspray ONE Replacement Spray Gun, 7100096183

4 × $308.73

3M 16579, Accuspray ONE Replacement Spray Gun, 7100096183

4 × $308.73 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

400 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

400 × $1.33 -

×

Standard Abrasives 840038, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, Maroon, 3/4 in, QS75KM, 7000121647, 50/case

50 × $0.84

Standard Abrasives 840038, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, Maroon, 3/4 in, QS75KM, 7000121647, 50/case

50 × $0.84 -

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

5 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

5 × $9.18 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97 -

×

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53 -

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04 -

×

3M 13718, Scotch-Brite EXL Unitized Wheel, XL-UW, 2S Fine, 3 in x 3/4 in x 1/4 in, 7000046025

10 × $18.37

3M 13718, Scotch-Brite EXL Unitized Wheel, XL-UW, 2S Fine, 3 in x 3/4 in x 1/4 in, 7000046025

10 × $18.37 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

80 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

80 × $11.06 -

×

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77 -

×

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69 -

×

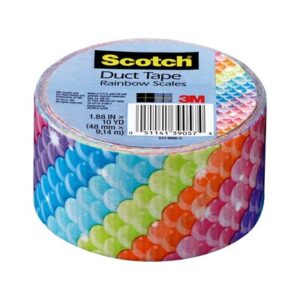

3M 37442, Scotch Duct Tape 910-CHV-C, 1.88 in x 10 yd (48 mm x 9,14 m), 7100183292

6 × $2.99

3M 37442, Scotch Duct Tape 910-CHV-C, 1.88 in x 10 yd (48 mm x 9,14 m), 7100183292

6 × $2.99 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76 -

×

3M 03016, Glass Cloth Tape 361, White, 3/4 in x 60 yd, 6.4 mil, 7000047441

48 × $89.62

3M 03016, Glass Cloth Tape 361, White, 3/4 in x 60 yd, 6.4 mil, 7000047441

48 × $89.62 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M 16028, PPS Lid & Liner Kit, Micro (3 fl oz), 200 Micron Full

Diameter Filter, 50 Lids & Liners per kit, 7000045465

1 × $94.69

3M 16028, PPS Lid & Liner Kit, Micro (3 fl oz), 200 Micron Full

Diameter Filter, 50 Lids & Liners per kit, 7000045465

1 × $94.69 -

×

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60 -

×

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

3M 35831, Hookit Dust Extraction Flexible Radius Sanding Block, 178 mm x 66 mm, 7100256512

24 × $45.74

3M 35831, Hookit Dust Extraction Flexible Radius Sanding Block, 178 mm x 66 mm, 7100256512

24 × $45.74 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

3M 76631, Roloc Disc 777F, TR, 3 in x NH, 36 YF-weight, 7000028339

200 × $1.61

3M 76631, Roloc Disc 777F, TR, 3 in x NH, 36 YF-weight, 7000028339

200 × $1.61 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 51332 .7 hp Router, 3-1/2" Base, Central Vacuum, 20,000 RPM, 1/4 Collet

1 × $1,277.00

Dynabrade 51332 .7 hp Router, 3-1/2" Base, Central Vacuum, 20,000 RPM, 1/4 Collet

1 × $1,277.00 -

×

3M 76975, Microfinishing PSA Film Disc 268L, 30 Mic, Type D, Green, 5 in x NH, Die 500X, 7000118196, 500 per case

500 × $1.15

3M 76975, Microfinishing PSA Film Disc 268L, 30 Mic, Type D, Green, 5 in x NH, Die 500X, 7000118196, 500 per case

500 × $1.15 -

×

3M 31959, 6450J, M125, 1" X 30", Type C, Pattern 18 Diamond Belts, 7100052712

1 × $0.00

3M 31959, 6450J, M125, 1" X 30", Type C, Pattern 18 Diamond Belts, 7100052712

1 × $0.00 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00 -

×

3M 76632, Roloc Disc 777F, 50 YF-weight, TR, 3 in, Die R300V, 7000045628

200 × $1.48

3M 76632, Roloc Disc 777F, 50 YF-weight, TR, 3 in, Die R300V, 7000045628

200 × $1.48 -

×

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.