-

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

480 × $2.04

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

480 × $2.04 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23 -

×

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30 -

×

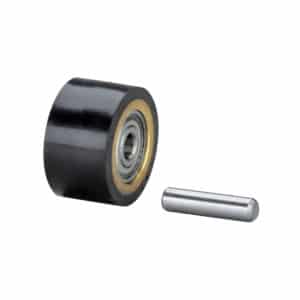

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49 -

×

Dynabrade 11305 Contact Arm Ass'y, 3/8" Dia. x 1" W, 40 Duro

1 × $90.75

Dynabrade 11305 Contact Arm Ass'y, 3/8" Dia. x 1" W, 40 Duro

1 × $90.75 -

×

Dynabrade 11066 Contact Wheel Ass'y, 5/16" Dia. x 1/8" W x 1/4" I.D., Flat Face, Steel

1 × $39.51

Dynabrade 11066 Contact Wheel Ass'y, 5/16" Dia. x 1/8" W x 1/4" I.D., Flat Face, Steel

1 × $39.51 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

80 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

80 × $11.50 -

×

Dynabrade 11070 Contact Wheel Ass'y, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

1 × $51.02

Dynabrade 11070 Contact Wheel Ass'y, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

1 × $51.02 -

×

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

50 × $4.48

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

50 × $4.48 -

×

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

12 × $5.83

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

12 × $5.83 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.06

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.06 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.70 -

×

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90 -

×

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08 -

×

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97

3M 85084, Finesse-it Knit II Buffing Pad, 85084, 3 in, 15/16 in Pile Height, 10/Bag, 50 ea/Case, 7000045701

$11.14

Factory Stock, 7-10 Day Leadtime

3M Finesse-it Knit II Buffing Pads are manufactured with wool fibers knit into a polyester fabric backing to apply the Finesse-it Finishing Material or Finesse-it Final Finish. These are ideal for buffing automotive OEM, marine, and aerospace coatings. These pads are trimmed to specified pile height, making ideal for compounding and polishing in hard to access areas.