-

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86 -

×

Dynabrade 68101 Coolant Filtration System, 230 V (AC), 1 Phase, 50 Hz

1 × $3,859.84

Dynabrade 68101 Coolant Filtration System, 230 V (AC), 1 Phase, 50 Hz

1 × $3,859.84 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $699.72 -

×

3M 82238, Scotch-Weld Epoxy Adhesive 420, Off-White, Part B, 5 Gallon Drum(Pail), 7100001145

5 × $327.91

3M 82238, Scotch-Weld Epoxy Adhesive 420, Off-White, Part B, 5 Gallon Drum(Pail), 7100001145

5 × $327.91 -

×

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99 -

×

Dynabrade 78141 4" Dia. x 1/2" Center Hole, Coarse, DynaStrip Disc

1 × $7.46

Dynabrade 78141 4" Dia. x 1/2" Center Hole, Coarse, DynaStrip Disc

1 × $7.46 -

×

Dynabrade 78776 3/8" x 1-1/2"-W176 Dynacut Cotton Fibre Fine DeBurring Mounted Point, 80MTX, 10/pack

10 × $61.00

Dynabrade 78776 3/8" x 1-1/2"-W176 Dynacut Cotton Fibre Fine DeBurring Mounted Point, 80MTX, 10/pack

10 × $61.00 -

×

3M 65087, Scotch-Brite Diamond Wheel, 3" x 1/2" x 3/8" 645DC, 7100083803

1 × $107.65

3M 65087, Scotch-Brite Diamond Wheel, 3" x 1/2" x 3/8" 645DC, 7100083803

1 × $107.65 -

×

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $573.77

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $573.77 -

×

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35 -

×

Insize 7261-250, INSIDE SPRING CALIPER, 10", 6928640319648

1 × $24.17

Insize 7261-250, INSIDE SPRING CALIPER, 10", 6928640319648

1 × $24.17 -

×

3M 50440, Green Corps Flexible Grinding Wheel, T27, 4-1/2 in x 1/8 in x 7/8 in, 36, 7000118590, 20 per case

20 × $7.26

3M 50440, Green Corps Flexible Grinding Wheel, T27, 4-1/2 in x 1/8 in x 7/8 in, 36, 7000118590, 20 per case

20 × $7.26 -

×

Dynabrade 62457 Screw

1 × $1.93

Dynabrade 62457 Screw

1 × $1.93 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35 -

×

Dynabrade 91641 2" W x 36" L 220 Grit A/O DynaCut Belt, 10/pack

10 × $5.81

Dynabrade 91641 2" W x 36" L 220 Grit A/O DynaCut Belt, 10/pack

10 × $5.81 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07 -

×

Dynabrade 56880 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $255.77

Dynabrade 56880 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $255.77 -

×

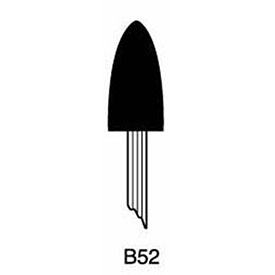

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41 -

×

Dynabrade 53249 9" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,531.52

Dynabrade 53249 9" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,531.52 -

×

Dynabrade 90380 2" W x 34" L 120 Grit A/O DynaCut Belt, 10/pack

10 × $5.73

Dynabrade 90380 2" W x 34" L 120 Grit A/O DynaCut Belt, 10/pack

10 × $5.73 -

×

3M 06839, Booth Coating, 1 Galllon, 7000028421

4 × $99.52

3M 06839, Booth Coating, 1 Galllon, 7000028421

4 × $99.52 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 66947, Trizact Cloth Belt 237AA, A100 X-weight, 3-1/2 in x 15-1/2 in, Film-lok, Full-flex, 7000028336, 50 per case

$11.59

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.