-

×

Standard Abrasives 32953, PSA A/O Disc, 711880, 2 in x NH, 60, 7010310798

100 × $0.00

Standard Abrasives 32953, PSA A/O Disc, 711880, 2 in x NH, 60, 7010310798

100 × $0.00 -

×

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

400 × $0.97 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

400 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

400 × $1.33 -

×

Insize 7341-12S, PIN GAGE HANDLE (with 1pc handle and 4 pairs of collecting bushes), .635-.704", 6928640360701

1 × $64.73

Insize 7341-12S, PIN GAGE HANDLE (with 1pc handle and 4 pairs of collecting bushes), .635-.704", 6928640360701

1 × $64.73 -

×

3M 66629, Cloth Belt 341D, 40 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118863, 20 per case

20 × $12.97

3M 66629, Cloth Belt 341D, 40 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118863, 20 per case

20 × $12.97 -

×

Standard Abrasives 707505, PSA A/O Disc, 12 in x NH, 40 Grit, 7010369974

10 × $6.35

Standard Abrasives 707505, PSA A/O Disc, 12 in x NH, 40 Grit, 7010369974

10 × $6.35 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 11000, Roloc Disc 361F, 24 YF-weight, TR, 2 in, Die R200P, 7000028183

200 × $1.25

3M 11000, Roloc Disc 361F, 24 YF-weight, TR, 2 in, Die R200P, 7000028183

200 × $1.25 -

×

Insize ISV-K1810, VIDEOSCOPE, lens diameter .071", cable length 40", 6940561973402

1 × $18,438.64

Insize ISV-K1810, VIDEOSCOPE, lens diameter .071", cable length 40", 6940561973402

1 × $18,438.64 -

×

Dynabrade 53245 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 8,500 RPM, 5/8"-11 Spindle

1 × $1,591.00

Dynabrade 53245 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 8,500 RPM, 5/8"-11 Spindle

1 × $1,591.00 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39 -

×

3M 30709, Cloth Belt 577F, 120 YF-weight, 1/2 in x 12 in, Fabri-lok, Single-flex, 7010363107, 200 per case

200 × $1.39

3M 30709, Cloth Belt 577F, 120 YF-weight, 1/2 in x 12 in, Fabri-lok, Single-flex, 7010363107, 200 per case

200 × $1.39 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

600 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

600 × $1.33 -

×

3M 76622, Roloc Disc 777F, 36 YF-weight, TR, 1 in, Die R100N, 7000045618

500 × $0.65

3M 76622, Roloc Disc 777F, 36 YF-weight, TR, 1 in, Die R100N, 7000045618

500 × $0.65 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

3M 41595, Polyurethane Sealant 540, Black, 310 mL Cartridge, 7100001804, 12/Case

12 × $9.58

3M 41595, Polyurethane Sealant 540, Black, 310 mL Cartridge, 7100001804, 12/Case

12 × $9.58 -

×

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

3M 66261, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7000049496, 12/Case

12 × $69.98

3M 66261, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7000049496, 12/Case

12 × $69.98 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 14559, Roloc Disc 361F, P150 XF-weight, TR, 2 in, Die R200P, 7000119021

200 × $0.97

3M 14559, Roloc Disc 361F, P150 XF-weight, TR, 2 in, Die R200P, 7000119021

200 × $0.97 -

×

3M 80299, Two-Handled Textured Surface Applicator TSA-4, Replacement Roller, 7000056164

1 × $110.21

3M 80299, Two-Handled Textured Surface Applicator TSA-4, Replacement Roller, 7000056164

1 × $110.21 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

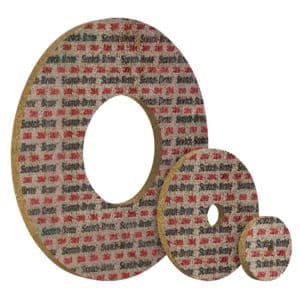

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 51204, Trizact Cloth Belt 237AA, A30 X-weight, 4 in x 90 in, Film-lok, Full-flex, 7010308049, 50 per case

$32.38

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.