-

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

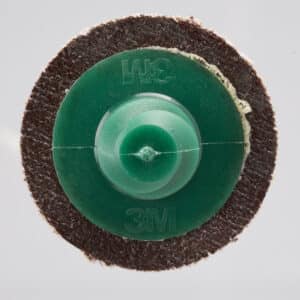

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18 -

×

3M 27611, Trizact Finesse-it Film Disc Roll 464LA, A5, 1-1/4 in x NH, Die 125C, 7000148157, 500 discs per roll

4 × $368.51

3M 27611, Trizact Finesse-it Film Disc Roll 464LA, A5, 1-1/4 in x NH, Die 125C, 7000148157, 500 discs per roll

4 × $368.51 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M 76679, Cloth Belt 777F, 60 YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118459, 20 per case

20 × $33.18

3M 76679, Cloth Belt 777F, 60 YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118459, 20 per case

20 × $33.18 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00 -

×

3M 26562, Cloth Belt 341D, 80 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7000118793, 50 per case

50 × $3.39

3M 26562, Cloth Belt 341D, 80 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7000118793, 50 per case

50 × $3.39 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M VHB Tape LSE-060WF, White, 8-1/2 in x 11 in, 25 mil, Sheet, 7100218678

This item has been Discontinued.

Scotch-Mount Outdoor Double-Sided Mounting Tape features 3M Industrial Strength Adhesive. Holding up to 15 lbs, this weather resistant tape can be used outdoor and is ideal on metal, vinyl siding and painted and finished wood.

Dream, Design, Deliver with the LSE Family of 3M VHB Tapes

The 3M VHB Tape LSE Series masters the challenge of low surface energy (LSE) bonding and delivers durable results. It offers superior bonding performance without primer on difficult to bond substrates such as PP, TPO, TPE, and composite materials. By eliminating the need for priming in your production, the LSE Series increases productivity and reduces the use of harsh chemicals in your facilities. Its excellent durability and wide range of temperature resistance ensures ultimate performance strength and reliability for in- and outdoor applications. The fast and easy to use permanent bonding method provides high strength and offers design flexibility with its viscoelasticity, making it an ideal fit for multi material bonding due to his properties on thermal expansion.

The LSE series of 3M VHB Tapes utilizes modified acrylic adhesive on both sides of a conformable, adhesive foam core. The combination of strength, conformability and adhesion makes this family one of the most capable and well-rounded 3M VHB Tapes. It masters the challenge of low surface energy (LSE) bonding and delivers durable results where other solutions need additional support on special surface treatment. It offers superior bonding performance on difficult to bond substrates such as PP, TPO, TPE, and composite materials including glass filled plastics, glass and carbon reinforced or gel coated composites as well as most polyester paints without primer. It also bonds well to many MSE plastics and metals. The modified acrylic construction makes the 3M VHB Tape LSE Series resist hot, cold and cycling temperatures, UV light, moisture and solvents and seals against environmental conditions. Its performance in a wide temperature range provides a durable alternative to rivets, welds and screws. 3M VHB Tape permanently adheres one substrate to another and spreads the stress load across the entire length of the joint. Once substrates are joined with high-strength bonding tape, a virtually indestructible “weld” is created.