-

×

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09 -

×

3M 42823, Electrically Conductive Double-Sided Tape 5113DFT-50, 500 mm x 30 m, 1 Roll/Case, 7100313602

1 × $1,181.57

3M 42823, Electrically Conductive Double-Sided Tape 5113DFT-50, 500 mm x 30 m, 1 Roll/Case, 7100313602

1 × $1,181.57 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

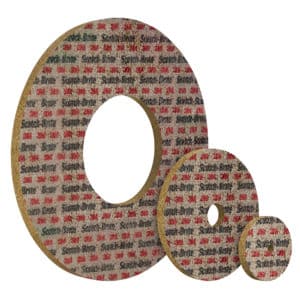

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

3M 16159, PTFE Glass Cloth Tape 5453, Brown, 3/4 in x 36 yd, 8.2 mil, 7000050132

12 × $193.37

3M 16159, PTFE Glass Cloth Tape 5453, Brown, 3/4 in x 36 yd, 8.2 mil, 7000050132

12 × $193.37 -

×

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00 -

×

3M 66635, Cloth Belt 341D, P100 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118867, 20 per case

20 × $9.47

3M 66635, Cloth Belt 341D, P100 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118867, 20 per case

20 × $9.47 -

×

3M 05612, Polyurethane Glass Adhesive Sealant 590, Black, 600 mL Sausage Pack, 7000121536, 12/Case

12 × $19.64

3M 05612, Polyurethane Glass Adhesive Sealant 590, Black, 600 mL Sausage Pack, 7000121536, 12/Case

12 × $19.64 -

×

3M 87179, Scotch-Weld Epoxy Adhesive 2216NS, Tan, Part B, 5 Gallon Drum (Pail), 7010309882

5 × $519.53

3M 87179, Scotch-Weld Epoxy Adhesive 2216NS, Tan, Part B, 5 Gallon Drum (Pail), 7010309882

5 × $519.53 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

ACS Diamond Cloth Belt, CX1250 5/8" X 120" 125U

9 × $47.60

ACS Diamond Cloth Belt, CX1250 5/8" X 120" 125U

9 × $47.60 -

×

3M 34672, 641WY, 1/2" X 64", 100 Mesh, Diamond Cloth Belts 7100111364

1 × $37.49

3M 34672, 641WY, 1/2" X 64", 100 Mesh, Diamond Cloth Belts 7100111364

1 × $37.49 -

×

3M 06742, Overspray Protective Sheeting, 20 ft x 250 ft, 7000120043

1 × $72.49

3M 06742, Overspray Protective Sheeting, 20 ft x 250 ft, 7000120043

1 × $72.49 -

×

3M 62818, Adhesive Sealant 760 UV, Black, 600 mL Sausage Pack, 7000121496, 12/Case

12 × $26.69

3M 62818, Adhesive Sealant 760 UV, Black, 600 mL Sausage Pack, 7000121496, 12/Case

12 × $26.69 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

3M 08374, MSP Sprayable Seam Sealer, Gray, 10.5 FL OZ Cartridge, 7000148239, 6 per case

6 × $27.39

3M 08374, MSP Sprayable Seam Sealer, Gray, 10.5 FL OZ Cartridge, 7000148239, 6 per case

6 × $27.39 -

×

Dynabrade 60052 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 35,000 RPM, 3/32" Collet

1 × $1,025.00

Dynabrade 60052 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 35,000 RPM, 3/32" Collet

1 × $1,025.00 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 06535, Marine Adhesive Sealant 5200FC Fast Cure, PN06535, White, 1 oz Tube, 7010367674, 12/Case

12 × $10.71

3M 06535, Marine Adhesive Sealant 5200FC Fast Cure, PN06535, White, 1 oz Tube, 7010367674, 12/Case

12 × $10.71 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M 07283, 3M PTFE Film Tape 5490, Brown, 2 in x 36 yd, 3.7 mil, 6 rolls per case, 7000050118

$285.98

Factory Stock, 7-10 Day Leadtime

3M PTFE Film Tape 5490 uses an extruded polytetrafluoroethylene (PTFE) film backing. This tape offers an extremely low coefficient of friction which, in combination with a pressure sensitive silicone adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in the movement of materials in many types of lay-flat applications.

Reduce Friction Between Moving Surfaces

The extruded film backing on 3M™ PTFE Film Tape 5490 resists curling when unwound from the roll and lies flatter than skived PTFE film tapes, creating a more uniform non-skid surface. We developed this tape as a quick and easy solution to reduce friction between moving surfaces. It functions as an anti-stick or easy-release medium where pressure, temperature changes and other factors may create a measure of adhesion. Applying 3M™ PTFE Film Tape 5490 can help improve surface movement, eliminate squeaks and rattles, and reduce machine noise. PTFE is chemical resistant and can be used as a temporary chemical barrier. The tape has a wide temperature use range, from -65°F/-54°C to 500°F/260°C, making it a suitable choice for a variety of applications.

Recommended Applications

- Roll-wrap for web processing, belts and plates where sticky materials and inks may occur

- High temperature wire bundling and harnessing

- Squeak and noise reduction

- Lining of chutes, toughs and ducts

- Shielding and protecting against chemicals

- Mold release for composite bonding

What is PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic material used in a variety of industries and applications to reduce the coefficient of friction. Because of its non-stick properties and high heat resistance, PTFE is used as a non-stick coating for frying pans and other cookware. It makes an excellent insulating material for electrical applications because of its non-conductivity. PTFE is non-reactive to numerous chemicals, due to the chemical resistance of fluoropolymer bonds; making it effective in containers and pipework for reactive and corrosive substances. PTFE reduces friction, wear and energy efficiency of machinery. Because of its low friction, PTFE is used in industrial applications where sliding action of parts is required, such as with bearings, gears, slide plates, etc. In these applications, it delivers significantly better performance than nylon or acetal. 3M has taken this versatile compound through an extrusion process to create a thin film, then paired the film with 3M’s unique pressure sensitive adhesives to make these PTFE tapes. Innovative, high performance 3M PTFE tapes are reliable, durable and reduce friction.