-

×

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

30 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

30 × $7.30 -

×

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19 -

×

3M 57545, Dry Layup Adhesive 2.0 W7900, color-change technology, 416g, aerosol, 7100062697, 12 Canisters/Case

12 × $26.73

3M 57545, Dry Layup Adhesive 2.0 W7900, color-change technology, 416g, aerosol, 7100062697, 12 Canisters/Case

12 × $26.73 -

×

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

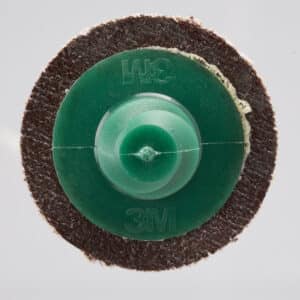

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

400 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

400 × $1.39 -

×

3M 45038, Wheel Adapter Kit No.3, 5/8-11 External, 7000028423

1 × $82.12

3M 45038, Wheel Adapter Kit No.3, 5/8-11 External, 7000028423

1 × $82.12 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

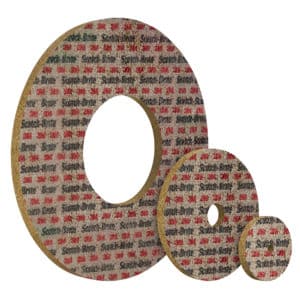

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56 -

×

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.81

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.81 -

×

3M 28625, DISC PAD FACE PLATE RIBBED 81732L, 5 IN EXTRA HARD RED, 7010362529

10 × $20.38

3M 28625, DISC PAD FACE PLATE RIBBED 81732L, 5 IN EXTRA HARD RED, 7010362529

10 × $20.38 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

3M 51033, Roloc Disc 361F, 36 YF-weight, TSM, 3 in, Die RS300VM, 7000148150

200 × $1.50

3M 51033, Roloc Disc 361F, 36 YF-weight, TSM, 3 in, Die RS300VM, 7000148150

200 × $1.50 -

×

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15 -

×

3M 26312, PPS Series 2.0 Spray Cup System Kit, Midi (13.5 oz, 400 mL),

125 Micron Filter, 7100169346

1 × $103.16

3M 26312, PPS Series 2.0 Spray Cup System Kit, Midi (13.5 oz, 400 mL),

125 Micron Filter, 7100169346

1 × $103.16

3M 26689, High Power Spray Gun Cleaner, 15 oz (426 g), 7100148476

$8.20

Factory Stock, 7-10 day Lead Time

Our 3M High Power Spray Gun Cleaner is a low VOC aerosol specifically formulated for removing waterborne and solvent-based coatings from metals, plastic and composite surfaces. This spray gun cleaner meets SCAQMD Rule 1171 requirements.

Cleanest Disposable Cup System

Every PPS™ Series 2.0 lid features a quarter-turn lid locking system to help reduce paint build-up and possible contamination. Additionally, each lid and liner kit contains a new hard cup which also features universal mixing ratios built into the cup, eliminating the need for separate inserts and helping ensure the most accurate mix possible.

Reduce Material Waste by Mixing in the Cup

3M™ PPS™ Series 2.0 makes it even easier to mix directly in the cup. If you’re mixing on a scale, use the max fill notation on each cup to fit the maximum amount. Cups include a clear access window to help you see how much material is left while spraying. The window also allows you to hold the liner for easier, cleaner lid removal. This is especially useful during refills or tinting.

Improved Fluid Flow for More Consistent Paint Application

Our 3M™ PPS™ Series 2.0 Lids feature a domed geometry that allows up to 3 oz (90mL) of material below the filter during on-demand spraying. This reduces sputter and other inconsistencies in spray performance. Lids also feature a wider spout for improved fluid flow. A built-in full-diameter filter delivers the highest quality filtration no assembly needed.

More Confidence in the Connection to Your Gun

A new adapter design provides a four-point connection and a wider 360 degree platform to ensure a stable, reliable lid-to-spray-gun connection. Larger sealing plugs do more than just seal. For instance, you can turn the cup upside down and use the new sealing plug as a base for temporary sealing and protecting, helping keep the built-in filter wet and reducing the need for replacement lids.

A System for Both Solvent-Based and Waterborne Products

Every lid features a built-in full diameter filter available in 200 micron or 125 micron mesh. Be sure to consult the paint or coatings manufacturer for the recommended filter mesh size.

Use the Right Size Cup for Every Repair

Our PPS™ 2.0 Spray Cup System is available in 5 sizes: 3 oz (90mL), 6.8 oz (200mL), 13.5 oz (400mL), 22 oz (650mL) and 28 oz (850mL). Using the right size cup for every repair not only reduces your cost per lid and liner, it can reduce the likelihood of overmixing.

Reduce Solvent Usage by up to 70%

After spraying, the painter can use the sealing plug to seal and protect the paint or coating for later use or simply discard the lid and liner, leaving only the adapter and spray gun to clean. Discard the disposable lid and liner in accordance with local government requirements. Use a small amount of solvent for cleaning the spray gun and the PPS? Adapter. Shops using PPS™ Series 2.0 often experience a 70% reduction in cleaning solvent usage. Most guns can be cleaned with less than 3 oz. of solvent.

Your Spray Gun Series 2.0 is a closed system, you can spray in any orientation to a full 360 degrees. This allows the painter to spray consistently at 90 degrees to the part, no matter how the part is positioned. It makes material transfer more consistent, limits paint overspray and reduces paint consumption.

Reduces the Chance of Contamination Between Jobs

Because the painter uses a new disposable lid and liner for each mix, there is less risk of outside contamination. Using a fresh lid and liner with each paint job, rather than washing out reusable components, often improves overall productivity in prep and clean-up time by as much as 50%.

The Bottom Line: Why 3M™ PPS™ Series 2.0 is the Disposable Cup of Choice

3M™ invented disposable cups for paint application and will continue to re-invent based on our customer’s feedback. What customers have taught us, is that trust and confidence in their disposable paint cup system is king. The consistent performance of the 3M™ PPS™ System has earned the trust of experts in one of the most important parts of a repair or manufacturing process paint application. PPS™ Series 2.0 is the culmination of more than 15 years of painter feedback and a true next generation all-in-one disposable painting system that produces cleaner jobs, saves on paint consumption and reduces solvent usage by up to 70%.