-

×

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $4.86

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $4.86 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.18

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.18 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.84

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.84 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.36

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.36 -

×

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.62

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.62 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

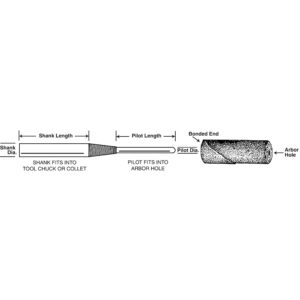

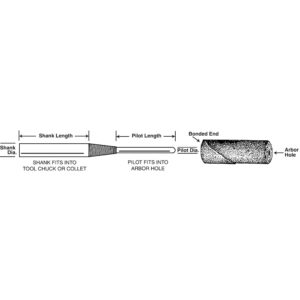

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56 -

×

Standard Abrasives 882173, A/O Unitized Wheel, 821, 6 in x 1/4 in x 1/2 in, 7010330323

10 × $38.87

Standard Abrasives 882173, A/O Unitized Wheel, 821, 6 in x 1/4 in x 1/2 in, 7010330323

10 × $38.87 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $573.77

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $573.77 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59 -

×

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16 -

×

Dynabrade 50303 4-1/2"- 5" (114 mm-127 mm) Dia. Vertical Depressed Center Wheel Grinder, 1.2 HP, 12,000 RPM, 5/8"-11 Spindle

1 × $1,128.30

Dynabrade 50303 4-1/2"- 5" (114 mm-127 mm) Dia. Vertical Depressed Center Wheel Grinder, 1.2 HP, 12,000 RPM, 5/8"-11 Spindle

1 × $1,128.30 -

×

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99 -

×

Dynabrade 61420 Raptor Vac Electric Portable Vacuum System

1 × $1,408.00

Dynabrade 61420 Raptor Vac Electric Portable Vacuum System

1 × $1,408.00 -

×

3M 29832, Sanding Screen, 150 Grit, 18 in x NH, 7100160831

12 × $6.21

3M 29832, Sanding Screen, 150 Grit, 18 in x NH, 7100160831

12 × $6.21 -

×

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,186.90

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,186.90 -

×

ACS Diamond Cloth Belt, CX1250 3" X 30" 75U

2 × $57.10

ACS Diamond Cloth Belt, CX1250 3" X 30" 75U

2 × $57.10 -

×

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35 -

×

Dynabrade 90123 - 12" x 12" Premium Microfiber Wipe, 10-Pack, Teal

1 × $64.54

Dynabrade 90123 - 12" x 12" Premium Microfiber Wipe, 10-Pack, Teal

1 × $64.54

3M 16348, PPS Liners, Mini (6 fl oz, 200 mL), 7100067924

$147.38

Factory Stock, 7-10 day Lead Time

3M PPS Liners come in cases containing 100 liners each for use with the 3M PPS paint preparation system. Liners are available for a range of jobs large and small. PPS is an all-in-one system that allows painters to mix/measure, filter, spray and temporarily seal and protect coating materials.

Bulk Lids for Added Efficiency with 3M™ PPS™

Excellent for stocking PPS™Lids efficiently and cost-effectively, 3M™ PPS™ Lids are available in cases containing 25 disposable lids with pre-welded micron filters for straining paint materials. Lids feature either 125 micron filters (light blue)), often recommended for water-borne paint materials; or 200 micron filters (clear) for traditional solvent-based paint materials. Always reference the paint manufacturer to ensure the recommended filter to strain the paint material.

Lids and sealing plugs are designed specifically for the 3M™ PPS™ paint preparation system. Lids are sized for the range of 3M™ PPS™ Cups, allowing technicians to up to 28 fluid oz (850 mL). Lid sizes include:

- 3M™ PPS™ Midi Lids for use with 13.5 fluid oz (400mL) 3M? PPS? Cups, ideal for spot and 2-panel repairs

- 3M™ PPS™ Standard and Large Lids for use with 22 fluid oz (650mL) and 28 fluid oz (850mL) PPS™ Cups, excellent for 3-panel and 4-panel repairs

Advantages of the 3M™ PPS™ System

Unlike conventional paint cup systems, our 3M™ PPS™ eliminates the need for mixing paint in additional paint mix cups and then transferring the paint through a separate filter into a paint reservoir. This is an important advantage because waste occurs every time that a user transfers paint through mixing cups and filters. With PPS™, you place the disposable liner within the re-usable PPS™ Cup. Then simply mix the paint in the PPS™ disposable liner, snap the disposable lid (with the pre-welded filter) in place and attach the locking collar to complete the PPS™ System. With just these few simple steps, you’re ready to start spraying.

Your Spray Gun Functions at any Angle, Even Upside Down

PPS™ allows the painter to spray consistently 90° to the part, no matter how the part is positioned. This makes material transfer more consistent, limits paint overspray and lowers paint consumption. Because PPS is a closed system, you can operate in any orientation – i.e. 360 degrees.

Clean Up is a Breeze and Uses Less Solvent

After spraying, the painter can use a sealing plug to seal and protect paint materials or simply discard disposable lid and liner, leaving only the adapter and spray gun to clean. Discard the disposable lid and liner in the appropriate approved waste containers specified by the paint manufacturer (or local government requirements). Use a small amount of solvent for cleaning the spray gun and the PPS™ adapter. With this disposable paint system, shops are often experiencing a 70% reduction in cleaning solvents, which means solvent cleaning savings and solvent disposal savings. Most guns can be cleaned with less than 3 oz. of solvent.

A Versatile System that Works with Most Spray Guns

Specifically designed PPS™ stainless steel metal adapters allow painters to use the PPS™ system with virtually any spray gun. Painters also have the option to use the 3M™ Accuspray™ ONE spray gun, which requires no adapters. Technicians have found that this spray gun further reduces cleaning solvent usage and cleaning and maintenance time.

Reduces the Chance of Contamination Between Jobs

Because the painter uses a new disposable lid (with welded-in filter) and disposable liner for each mix, there is less risk of outside contamination due to mixing, filtering and clean up. Using a fresh lid and liner with each paint job, rather than washing out reusable components, often improves overall productivity in prep and clean-up time by as much as 50%.

The Bottom Line: Why 3M™ PPS™ is the Paint and Coatings Spray System of Choice

3M™ PPS™ is an all-in-one disposable painting system that produces cleaner jobs, saves on paint consumption and reduces solvent usage by up to 70%. You’ll find that technicians operate with greater efficiency and spend less time on cleaning tasks. 3M PPS offers many advantages for any one spraying liquid coatings from a spray gun with cup.