-

×

Dynabrade 51854 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $683.00

Dynabrade 51854 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $683.00 -

×

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71 -

×

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

Standard Abrasives 725008, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7000046829

50 × $3.13

Standard Abrasives 725008, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7000046829

50 × $3.13 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32 -

×

3M 35828, Hookit Dust Extraction Flexible Sanding Block, 406 mm x 67 mm, 7100256624

8 × $63.98

3M 35828, Hookit Dust Extraction Flexible Sanding Block, 406 mm x 67 mm, 7100256624

8 × $63.98 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

3M 20931, PSA Cloth Disc 348D, P100 X-weight, 1 in x NH, Die 100N, 7000118915

500 × $0.39

3M 20931, PSA Cloth Disc 348D, P100 X-weight, 1 in x NH, Die 100N, 7000118915

500 × $0.39 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

2 × $1,585.00 -

×

3M 26114, PPS Series 2.0 Spray Cup System Kit, Mini (6.8 fl oz, 200

mL), 200u Micron Filter, 7100135935

1 × $103.26

3M 26114, PPS Series 2.0 Spray Cup System Kit, Mini (6.8 fl oz, 200

mL), 200u Micron Filter, 7100135935

1 × $103.26 -

×

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00 -

×

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

400 × $4.46

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

400 × $4.46 -

×

3M 66608, Pomp Plus Probed Test Plugs 393-2017-50, 50 Pair/Case, 7010301959

1 × $100.28

3M 66608, Pomp Plus Probed Test Plugs 393-2017-50, 50 Pair/Case, 7010301959

1 × $100.28 -

×

Dynabrade 10295 Screen

1 × $4.58

Dynabrade 10295 Screen

1 × $4.58 -

×

Standard Abrasives 725013, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000046831

50 × $4.73

Standard Abrasives 725013, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000046831

50 × $4.73 -

×

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 92209 1/8" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 92209 1/8" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

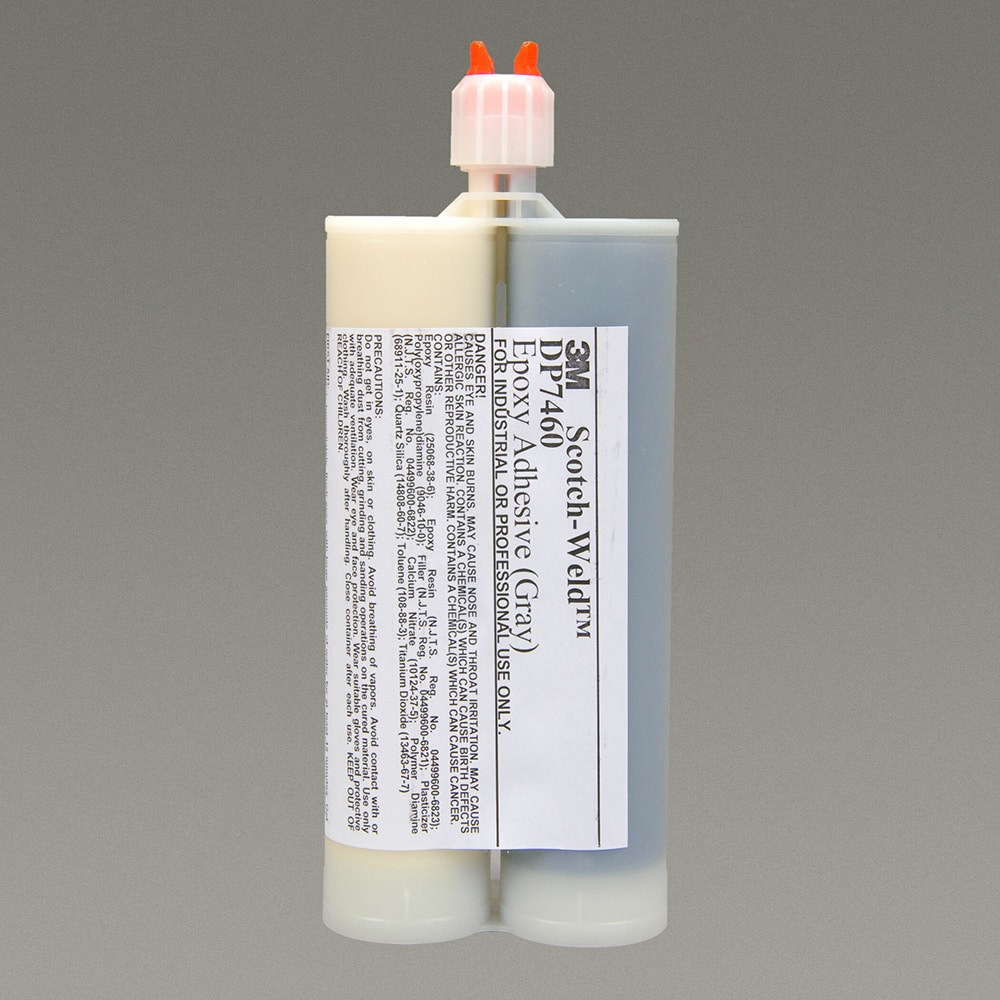

3M 63426, Scotch-Weld Toughened Epoxy Adhesive LSB60NS, Gray, 400 mL Duo-Pak, 7000046491, 6/case

$132.24

Factory Stock, 7-10 Day Leadtime

3M Scotch-Weld Toughened Epoxy Adhesive LSB60NS is a gray, high performance, non-sag, two-part toughened epoxy adhesive that offers good shear adhesion and high durability. With a 90 minute work life and 1:1 mix ratio, this epoxy adhesive is often used for bulk application through meter mix dispensing equipment and the manufacture of large panel products including honeycomb panels.

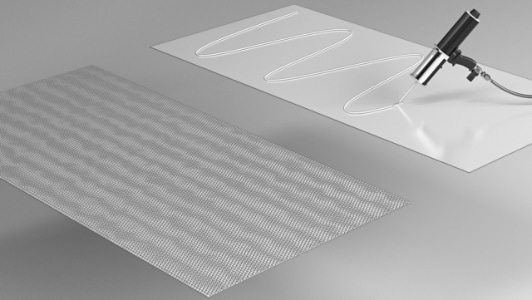

When using a Duo-Pak (DP) size adhesive, rely on 3M dispensing equipment for convenient and accurate metering, mixing and dispensing.

Used in large structure bonding for aluminum honeycomb panels

Works Efficiently for Large Structure Bonding

Unlike using screws or rivets, 3M™ Scotch-Weld™ Toughened Epoxy Adhesive LSB60NS lets you distribute stress uniformly over the entire bonded area while maintaining surface integrity and the physical properties of the panel. It allows you to use thinner, lighter panel materials without worrying about distortion, splitting, or crazing and will secure even small or thin bonding edges. Offering high resistance against shock and vibration, it features good shear and peel adhesion with high levels of durability.

Recommended Applications

- Delivery truck side walls

- Metal enclosure facing and cabinets

- Panels to frame

90 Minute Work Life Provides Ample Time for Positioning and Adjustment

This epoxy dispenses as a medium viscosity adhesive for easy, controlled dispensing. The adhesive reaches handling strength in approximately 6 hours and is fully cured in 7 days at 73°F (23°C).The mix ratio is 1:1 and provides a 90 minute work life, providing ample time to adjust for desired fit prior to curing. 3M™ Scotch-Weld™ Toughened Epoxy Adhesive LSB60NS is ideal for bulk application through meter mix dispensing equipment and the manufacture of large panel products.

Understanding Epoxy Adhesives

Epoxy adhesives are part of the class of adhesives called “structural adhesives,” which also includes polyurethane, acrylic, cyanoacrylate and others. Epoxies are formulated as liquid reactive polymers that undergo a chemical reaction when mixed and then cure to form a solid plastic material. Once the two parts are mixed in their specified ratio, they begin the curing process and offer a limited working time where the adhesive can be applied and the two surfaces positioned as needed. This work life lasts anywhere from a few minutes to several hours. These structural adhesives provide high shear and peel strengths, depending on the formula, and better heat and chemical resistance than other common adhesives. In general, epoxy adhesives have the highest overall strength and offer the best performance and most resistance to high temperatures, solvents and outdoor weathering.

Epoxy adhesives are widely used in building and home construction; aircraft and automobile manufacturing; bicycle, boat, golf clubs, ski and snowboard assembly as well as a host of home use and other applications. They are used virtually anywhere high-strength bonds are needed along with resistance to environmental conditions. These adhesives are popular for their ease of use, mechanical strength and chemical resistance. Formulations can be created to make epoxies flexible or rigid, transparent or opaque, quick setting or slow setting. The versatility with which epoxy adhesives can be formulated helps meet almost any requirement for bonding wood, metal, glass, stone and various plastics.

Industrial uses for epoxies range widely and, in addition to adhesives, include coatings and composite materials like carbon fiber and glass-reinforced composites. They are the preferred choice due to their ability to flow and conform to the work area, strong adhesion, chemical and heat resistance and exceptional mechanical and electrical insulating properties.

Bringing Better Ideas to the Surface through Science and Innovation

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the desig

Related products

Adhesives & Sealants

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

$126.95