-

×

Insize 7332, SPINDLE LIFT KNOB, 6928640312649

1 × $4.60

Insize 7332, SPINDLE LIFT KNOB, 6928640312649

1 × $4.60 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

3M 82460, Stikit Gold Film Disc Roll 255L, P500, 5 in x NH, Die 500X, 7010308367, 125 discs per roll

4 × $87.58

3M 82460, Stikit Gold Film Disc Roll 255L, P500, 5 in x NH, Die 500X, 7010308367, 125 discs per roll

4 × $87.58 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 71600, Scotch-Weld Structural Plastic Adhesive DP8010, Blue, 45 mL Duo-Pak, 7100036717, 12/case

12 × $58.25

3M 71600, Scotch-Weld Structural Plastic Adhesive DP8010, Blue, 45 mL Duo-Pak, 7100036717, 12/case

12 × $58.25

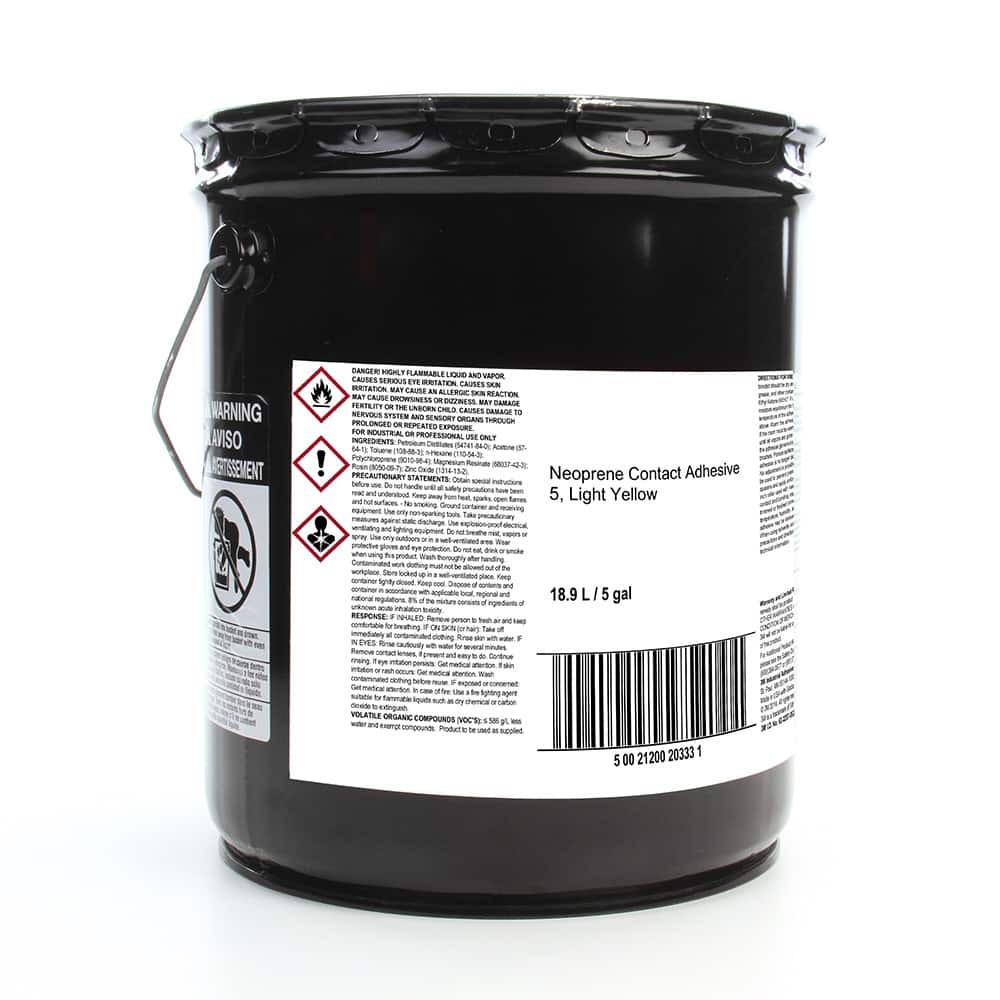

3M 20333, Neoprene Contact Adhesive 5, Light Yellow, 5 Gallon Drum (Pail), 7010367231

$64.47

Factory Stock, 7-10 Day Leadtime

3M Neoprene Contact Adhesive 5 is a versatile, solvent based adhesive with a low viscosity for spraying. It offers high immediate handling strength and good heat resistance, and is commonly used for bonding most metals and plastics. It is also suitable for large surface panel or composite lamination.