-

×

3M 29844, Sanding Screen, 120 Grit, 16 in x NH, 7100160823

12 × $5.17

3M 29844, Sanding Screen, 120 Grit, 16 in x NH, 7100160823

12 × $5.17 -

×

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

Dynabrade 98263 3/8" NPT Male Plug

1 × $24.50

Dynabrade 98263 3/8" NPT Male Plug

1 × $24.50 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

3M 14270, Disc Pad Face Plate, 4-1/2 in Hard Black, 7000144144

1 × $17.76

3M 14270, Disc Pad Face Plate, 4-1/2 in Hard Black, 7000144144

1 × $17.76 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 29835, Sanding Screen, 80 Grit, 18 in x NH, 7100160844

12 × $9.18

3M 29835, Sanding Screen, 80 Grit, 18 in x NH, 7100160844

12 × $9.18 -

×

3M 06564, Marine Adhesive Sealant 4200FC Fast Cure, Black, 295 mL Cartridge, 7000120497, 12/Case

12 × $25.30

3M 06564, Marine Adhesive Sealant 4200FC Fast Cure, Black, 295 mL Cartridge, 7000120497, 12/Case

12 × $25.30 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 05048, Cloth Belt 384F, 80+ XF-weight, 1 in x 12 in, Fabri-lok, Full-flex, 7100141432, 200 per case

200 × $1.57

3M 05048, Cloth Belt 384F, 80+ XF-weight, 1 in x 12 in, Fabri-lok, Full-flex, 7100141432, 200 per case

200 × $1.57 -

×

Standard Abrasives 725013, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000046831

50 × $4.73

Standard Abrasives 725013, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000046831

50 × $4.73 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M 01000, Scotch-Weld EPX 1:1/2:1 Plunger for EPX Plus II Applicator, 48.5 mL/50 mL, 7010415317

10 × $12.60

3M 01000, Scotch-Weld EPX 1:1/2:1 Plunger for EPX Plus II Applicator, 48.5 mL/50 mL, 7010415317

10 × $12.60 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92 -

×

3M 16325, PPS Lid & Liner Kit, Large (28 fl oz), 125 Micron Full

Diameter Filter, 25 Lids & Liners per kit, 7100003284

1 × $70.50

3M 16325, PPS Lid & Liner Kit, Large (28 fl oz), 125 Micron Full

Diameter Filter, 25 Lids & Liners per kit, 7100003284

1 × $70.50 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

3M 98242, Marine Adhesive Sealant 3000 UV, Black, 290 mL Cartridge, 7100111111, 12/Case

12 × $13.17

3M 98242, Marine Adhesive Sealant 3000 UV, Black, 290 mL Cartridge, 7100111111, 12/Case

12 × $13.17 -

×

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37 -

×

3M 92768, Heavy Duty Stripping Tool 10110NA-PT, 3 Coarse, One, Open Stock, 3.375 in. x 5 in. Handle and Pad, 7010292604

6 × $4.17

3M 92768, Heavy Duty Stripping Tool 10110NA-PT, 3 Coarse, One, Open Stock, 3.375 in. x 5 in. Handle and Pad, 7010292604

6 × $4.17 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

3M 29842, Sanding Screen, 180 Grit, 16 in x NH, 7100160822

12 × $4.58

3M 29842, Sanding Screen, 180 Grit, 16 in x NH, 7100160822

12 × $4.58 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25 -

×

Insize 7260-250, SPRING DIVIDER, 10", 6928640319723

1 × $24.17

Insize 7260-250, SPRING DIVIDER, 10", 6928640319723

1 × $24.17 -

×

Dynabrade 78292 2" Dia. x 6A M Medium Type R Unitized Locking-Type Disc, 25/pack

25 × $7.57

Dynabrade 78292 2" Dia. x 6A M Medium Type R Unitized Locking-Type Disc, 25/pack

25 × $7.57

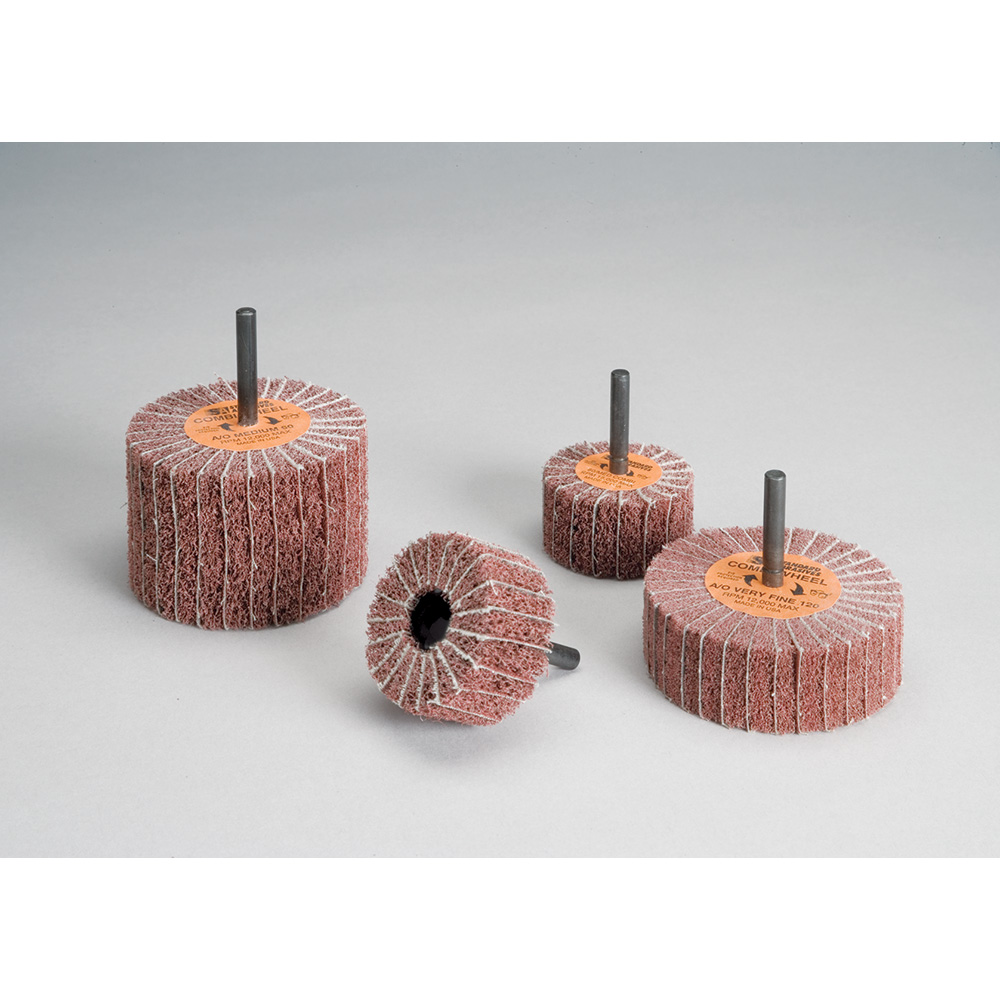

Standard Abrasives 898000, Buff and Blend Combi-Wheel, 2 in x 1 in x 1/4 in A MED 60, 7010331222

$16.32

Factory Stock, 7-10 Day Leadtime

For added cut, the Standard Abrasives Buff and Blend Combi-Wheel features alternating flaps of Buff and Blend non-woven GP material and coated abrasive resin bonded material. The combination of flaps blends and removes contaminants more aggressively than a non-woven brush, while producing a uniform final finish with a linear scratch pattern.

For added cut, we designed our Standard Abrasives™ Buff and Blend Combi-Wheel with alternating flaps of Buff and Blend non-woven GP material and coated abrasive resin bonded material. The combination of flaps blends and removes contaminants more aggressively than a non-woven brush, while producing a uniform final finish with a linear scratch pattern.

(Long)

Versatile Utility and Linear Scratch Pattern

The Standard Abrasives™ Buff and Blend Combi-Wheel is a versatile product that is a great follow-up to coated abrasive steps in operations where a linear scratch pattern is desired. Use it to remove heavy oxidation prior to painting or plating, finish stamped or extruded aluminum parts, add a grain finish to stainless steel sheets, or create a satin finish on other large surfaces. It is suitable for ferrous and non-ferrous metals.

Added Strength for Demanding Finishing Applications

The durable construction of Combi-Wheel flaps provides aggressive, controlled action and a consistent, uniform finish. The Buff and Blend flaps are made from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain. The Combi-Wheel is more aggressive than a flap brush, which does not incorporate coated abrasive flaps, and less aggressive than a flap wheel, which is entirely constructed from coated abrasive flaps. In applications where a flap brush needs some extra teeth for blending or cleaning, the addition of coated abrasive flaps in a Combi-Wheel provides added abrasive strength.

To suit a variety of large and small finishing operations, we offer this popular product in a broad range of sizes and in two grades, medium (MED) and very fine (VFN).

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend material is load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure optimal performance on specific applications.

Related products

Multi-Finishing Wheels

3M 13180, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Medium, 6 in x 3 in x 1 in, 7000148248

$133.38