-

×

Dynabrade 95886 Washers For Vacuum Shroud (57737)

1 × $1.93

Dynabrade 95886 Washers For Vacuum Shroud (57737)

1 × $1.93 -

×

Dynabrade 53091 3/8" Pistol Grip Drill, .7 HP, Rear Exhaust, 950 RPM

1 × $1,137.93

Dynabrade 53091 3/8" Pistol Grip Drill, .7 HP, Rear Exhaust, 950 RPM

1 × $1,137.93 -

×

Dynabrade 11135 - 1/2" (13 mm) x 2" (51 mm) Hard Platen Pad

1 × $4.71

Dynabrade 11135 - 1/2" (13 mm) x 2" (51 mm) Hard Platen Pad

1 × $4.71 -

×

Dynabrade 50081 Flange

1 × $45.40

Dynabrade 50081 Flange

1 × $45.40 -

×

Dynabrade 53166 Handle Support

1 × $150.75

Dynabrade 53166 Handle Support

1 × $150.75 -

×

Dynabrade 55396 Front End Plate, Vaned Pencil Grinder

1 × $25.55

Dynabrade 55396 Front End Plate, Vaned Pencil Grinder

1 × $25.55 -

×

Dynabrade 54783 3" (76 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

2 × $1,024.22

Dynabrade 54783 3" (76 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

2 × $1,024.22 -

×

Dynabrade ROB2 - 6" Nitro Series Electric Random Orbital Buffer

1 × $424.55

Dynabrade ROB2 - 6" Nitro Series Electric Random Orbital Buffer

1 × $424.55 -

×

Dynabrade 40565 O-Ring

1 × $1.91

Dynabrade 40565 O-Ring

1 × $1.91 -

×

Dynabrade 33672 ND6230, Piston Drive Pin Bushing Assembly

1 × $43.90

Dynabrade 33672 ND6230, Piston Drive Pin Bushing Assembly

1 × $43.90 -

×

Dynabrade 96456 - 1/4" NPT Female Hose Adaptor

1 × $18.25

Dynabrade 96456 - 1/4" NPT Female Hose Adaptor

1 × $18.25 -

×

Dynabrade 63603 RaptorVac PowerHead Replacement for 61203

1 × $1,391.25

Dynabrade 63603 RaptorVac PowerHead Replacement for 61203

1 × $1,391.25 -

×

Dynabrade 52377 3" (76 mm) Dia. Straight-Line Type 1 Extension Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $866.78

Dynabrade 52377 3" (76 mm) Dia. Straight-Line Type 1 Extension Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $866.78 -

×

Dynabrade 42720 Ball Bearing

1 × $26.43

Dynabrade 42720 Ball Bearing

1 × $26.43 -

×

Dynabrade 89314 Gear Box Housing

1 × $47.86

Dynabrade 89314 Gear Box Housing

1 × $47.86 -

×

Dynabrade 51400 3" Dia. 7 Degree Offset Rotary Buffer, .4 hp, 3,200 RPM, Rear Exhaust, 3/8"-24 Spindle Thread

1 × $791.57

Dynabrade 51400 3" Dia. 7 Degree Offset Rotary Buffer, .4 hp, 3,200 RPM, Rear Exhaust, 3/8"-24 Spindle Thread

1 × $791.57 -

×

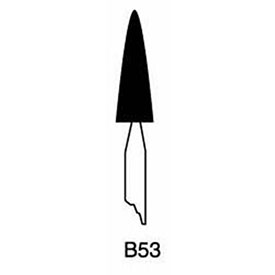

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.46

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.46 -

×

Dynabrade 52675 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 9,000 RPM, 1/4" Collet

1 × $728.59

Dynabrade 52675 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 9,000 RPM, 1/4" Collet

1 × $728.59 -

×

Dynabrade 54775 4" (102 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

2 × $911.39

Dynabrade 54775 4" (102 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

2 × $911.39 -

×

Dynabrade 57334 Counter Balance

1 × $90.63

Dynabrade 57334 Counter Balance

1 × $90.63 -

×

Dynabrade 56890 6" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $255.77

Dynabrade 56890 6" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $255.77 -

×

Dynabrade X52 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/32" Orbit, PSA

1 × $213.35

Dynabrade X52 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/32" Orbit, PSA

1 × $213.35 -

×

Dynabrade 57083 Vacuum Adapter

1 × $16.64

Dynabrade 57083 Vacuum Adapter

1 × $16.64 -

×

Dynabrade 13500 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 950 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,186.90

Dynabrade 13500 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 950 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,186.90 -

×

Dynabrade 98265 3/8" Female Coupler with 3/8" Male Plug Assembly

2 × $86.59

Dynabrade 98265 3/8" Female Coupler with 3/8" Male Plug Assembly

2 × $86.59 -

×

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 50296 5" Dia. Disc Backup Pad, Hard Density, 5/8"-11 Thread

1 × $34.17

Dynabrade 50296 5" Dia. Disc Backup Pad, Hard Density, 5/8"-11 Thread

1 × $34.17 -

×

Dynabrade 78020 1/2" W x 18" L Medium NWN DynaBrite Belt, 10/pack

10 × $5.62

Dynabrade 78020 1/2" W x 18" L Medium NWN DynaBrite Belt, 10/pack

10 × $5.62 -

×

Dynabrade 54911 Gear Set, 6500 RPM, 2.6Hp

1 × $417.36

Dynabrade 54911 Gear Set, 6500 RPM, 2.6Hp

1 × $417.36 -

×

Dynabrade 53918 Housing for Model 51804

1 × $86.83

Dynabrade 53918 Housing for Model 51804

1 × $86.83 -

×

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

Dynabrade 53053 Chuck Key for 53033, 53087 Chuck

1 × $34.17

Dynabrade 53053 Chuck Key for 53033, 53087 Chuck

1 × $34.17 -

×

Dynabrade 95756 Speed Control for Extreme Dynorbital Sanders

1 × $26.05

Dynabrade 95756 Speed Control for Extreme Dynorbital Sanders

1 × $26.05 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93 -

×

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95 -

×

Dynabrade 21432 ND220, Vane 5/Pack

1 × $21.89

Dynabrade 21432 ND220, Vane 5/Pack

1 × $21.89 -

×

Dynabrade 11206 Contact Arm Ass'y, 3/4" Dia. x 5/8" W, Rubber Wheel, with 3/4" (19 mm) W Platen

1 × $80.85

Dynabrade 11206 Contact Arm Ass'y, 3/4" Dia. x 5/8" W, Rubber Wheel, with 3/4" (19 mm) W Platen

1 × $80.85 -

×

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53 -

×

Dynabrade 58502 3" W x 4-1/4" L Dynabug II Orbital Sander, Central Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $250.15

Dynabrade 58502 3" W x 4-1/4" L Dynabug II Orbital Sander, Central Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $250.15 -

×

Dynabrade 55406 Overhose, Vaned PG

1 × $42.95

Dynabrade 55406 Overhose, Vaned PG

1 × $42.95 -

×

Dynabrade 53251 7" Dia. Vertical Disc Sander

1 × $1,407.32

Dynabrade 53251 7" Dia. Vertical Disc Sander

1 × $1,407.32 -

×

Dynabrade 52760 5" Dia. Sander w/Random-Rotary Orbit Locking Head

1 × $917.51

Dynabrade 52760 5" Dia. Sander w/Random-Rotary Orbit Locking Head

1 × $917.51 -

×

Dynabrade 92245 - 4" (102 mm) Dia. x 3/4" (19 mm) W Bent Coarse Wire Wheel

1 × $44.87

Dynabrade 92245 - 4" (102 mm) Dia. x 3/4" (19 mm) W Bent Coarse Wire Wheel

1 × $44.87 -

×

Dynabrade 53880 Housing for Model 52317

1 × $102.11

Dynabrade 53880 Housing for Model 52317

1 × $102.11 -

×

Dynabrade 53885 Housing For Model 51847

1 × $102.11

Dynabrade 53885 Housing For Model 51847

1 × $102.11 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15 -

×

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99 -

×

Dynabrade 93351 Carbide Burr 12-Piece Burr Kit, 1/8" Shank

1 × $216.84

Dynabrade 93351 Carbide Burr 12-Piece Burr Kit, 1/8" Shank

1 × $216.84 -

×

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

Dynabrade 53917 Housing For Model 51803

1 × $86.83

Dynabrade 53917 Housing For Model 51803

1 × $86.83 -

×

Dynabrade 54907 Bearing- 19 x 7 x 6

1 × $21.89

Dynabrade 54907 Bearing- 19 x 7 x 6

1 × $21.89 -

×

Dynabrade 54947 Spring, Throttle Ball

1 × $4.28

Dynabrade 54947 Spring, Throttle Ball

1 × $4.28 -

×

Dynabrade 55402 Air Manifold Seat, Vaned Pencil Grinder

1 × $12.63

Dynabrade 55402 Air Manifold Seat, Vaned Pencil Grinder

1 × $12.63 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 95990 Wet Tank Assembly

1 × $137.01

Dynabrade 95990 Wet Tank Assembly

1 × $137.01 -

×

Standard Abrasives 840338, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, MAR, 2 in, Die QS200PM, 7000121650, 50/case

50 × $1.36

Standard Abrasives 840338, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, MAR, 2 in, Die QS200PM, 7000121650, 50/case

50 × $1.36

Standard Abrasives 875500, Buff and Blend GP Mounted Flap Brush, Medium, 2 in x 2 in x 1/4 in, 7000122217

$19.12

Factory Stock, 7-10 Day Leadtime

Both tough and pliable, our Standard Abrasives Buff and Blend Mounted GP Flap Brush is a good match for light to medium-duty cleaning and deburring applications on contours or uneven surfaces. Multi-purpose GP material leaves a consistent finish on irregular surfaces and suits a variety of metals, including ferrous alloys. The attached mandrel securely fastens to small straight tools with ease.

Moderately Aggressive for Light to Medium-Duty Applications

Our Standard Abrasives™ Buff and Blend GP Mounted Flap Brush is a great multi-purpose product for industrial maintenance applications. Among Buff and Blend materials, GP material is moderately aggressive. Use it to remove light oxidation, blend minor surface imperfections, clean surfaces prior to coatings, remove small burrs, and perform basic equipment cleanup. A flexible open web conforms to workpiece contours, curves and ridges. Its non-woven construction makes the flaps spongy and responsive. When the job requires a tougher product for higher-pressure applications, we recommend using a Standard Abrasives™ Buff and Blend HS Flap Brush.

Using Standard Abrasives™ Buff and Blend discs, wheels and brushes, operators can tackle ridges and contours with less concern about gouging or marring the substrate, thus reducing waste and the need for rework.

Aluminum Oxide Offers Fast Cut

This flap brush is made with aluminum oxide mineral, which cuts sharp but is still friable – fragmenting under heat and pressure to reveal sharp cutting edges. The tan, MED brush delivers a somewhat coarse scratch pattern, suitable for satin or matte finishes, while the gray VFN brush provides a finer finish.

Consistent Finishes, Operator Comfort

Flap brushes produce a consistent finish which does not reflect lines commonly attributed to ganged arbor hole discs. Density, pressure and angle determine the ability of the flap brush to remove burrs, oxidation and handling marks. The abrasive material provides ventilation which helps dissipate heat and, therefore, runs cooler. This provides consistent finishes without smearing or otherwise discoloring the work piece. Minimal vibration can reduce chattermarks on the workpiece and can lead to less operator and machine fatigue.

The permanently affixed 1/4? shank enables convenient use on small straight pneumatic and electric grinders, and provides smooth running and ease of control for off-hand operations.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.