-

×

Standard Abrasives 37446, PSA A/O Disc, 700595, 1-1/2 in x NH, 60, 7010331822

100 × $0.24

Standard Abrasives 37446, PSA A/O Disc, 700595, 1-1/2 in x NH, 60, 7010331822

100 × $0.24 -

×

Dynabrade 14200 Dynangle Abrasive Belt Tool

1 × $1,280.00

Dynabrade 14200 Dynangle Abrasive Belt Tool

1 × $1,280.00 -

×

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30 -

×

Dynabrade 31991 - 3/4" to 1" Vacuum Whip Hose 4" Long w/Swivel Adaptor

1 × $61.44

Dynabrade 31991 - 3/4" to 1" Vacuum Whip Hose 4" Long w/Swivel Adaptor

1 × $61.44 -

×

Dynabrade 15300 Dynafile III Abrasive Belt Tool

1 × $940.00

Dynabrade 15300 Dynafile III Abrasive Belt Tool

1 × $940.00 -

×

Dynabrade 58365 Tip Valve

1 × $9.63

Dynabrade 58365 Tip Valve

1 × $9.63 -

×

Dynabrade 61202 RaptorVac Pneumatic DrumVac Kit, Single Operator, General Purpose

1 × $2,268.04

Dynabrade 61202 RaptorVac Pneumatic DrumVac Kit, Single Operator, General Purpose

1 × $2,268.04 -

×

Standard Abrasives 853254, S/C Unitized Wheel, 532, 4 in x 1/4 in x 1/4 in, 7000121888

10 × $14.35

Standard Abrasives 853254, S/C Unitized Wheel, 532, 4 in x 1/4 in x 1/4 in, 7000121888

10 × $14.35 -

×

Standard Abrasives 854793, Deburring Wheel, 8 in x 1/2 in x 3 in 9S FIN, 7010330359

4 × $73.36

Standard Abrasives 854793, Deburring Wheel, 8 in x 1/2 in x 3 in 9S FIN, 7010330359

4 × $73.36 -

×

Standard Abrasives 850373, GP Wheel 6 in x 1/2 in x 1 in 9S FIN, 7010299543

5 × $34.68

Standard Abrasives 850373, GP Wheel 6 in x 1/2 in x 1 in 9S FIN, 7010299543

5 × $34.68 -

×

Dynabrade 47212 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 5,000 RPM, 1/4" Collet

1 × $701.00

Dynabrade 47212 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 5,000 RPM, 1/4" Collet

1 × $701.00 -

×

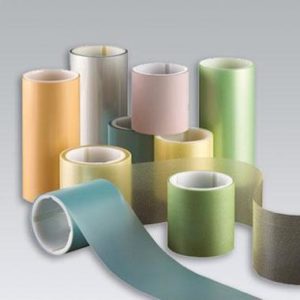

Dynabrade 92740 2" W x 150' L 30 Micron A/O Lapping Film DynaCut Roll

1 × $127.40

Dynabrade 92740 2" W x 150' L 30 Micron A/O Lapping Film DynaCut Roll

1 × $127.40 -

×

Dynabrade 48335 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $487.00

Dynabrade 48335 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $487.00 -

×

Dynabrade 95848 Dynabrade Gear Oil

2 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

2 × $12.98 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

ACS 2" Diamond Disc, 60 Mesh, W/ Metal Button

2 × $15.00

ACS 2" Diamond Disc, 60 Mesh, W/ Metal Button

2 × $15.00 -

×

Standard Abrasives 890194, S/C Unitized Wheel, 632, 12 in x 1/4 in x 1-1/4 in, 7010367081

10 × $105.90

Standard Abrasives 890194, S/C Unitized Wheel, 632, 12 in x 1/4 in x 1-1/4 in, 7010367081

10 × $105.90 -

×

Dynabrade 18410 Safety Lever Spring

1 × $2.22

Dynabrade 18410 Safety Lever Spring

1 × $2.22 -

×

3M 15996, Venture Tape UL181B-FX Polypropylene Duct Tape 1599B, Silver, 48 mm x 109.7 m, 3 mil, 7100043760

24 × $14.94

3M 15996, Venture Tape UL181B-FX Polypropylene Duct Tape 1599B, Silver, 48 mm x 109.7 m, 3 mil, 7100043760

24 × $14.94 -

×

Standard Abrasives 890229, S/C Unitized Wheel, 632, 8 in x 1/2 in x 3 in, 7010310368

10 × $84.53

Standard Abrasives 890229, S/C Unitized Wheel, 632, 8 in x 1/2 in x 3 in, 7010310368

10 × $84.53 -

×

Dynabrade 52439 3" (76 mm) Dia. Right Angle Diamond Cut-Off Wheel Tool

1 × $754.00

Dynabrade 52439 3" (76 mm) Dia. Right Angle Diamond Cut-Off Wheel Tool

1 × $754.00 -

×

Standard Abrasives 811532, Type 27 Unitized Wheel, 532, 4-1/2 in x 1/2 in x 7/8 in, 7000047219

5 × $23.24

Standard Abrasives 811532, Type 27 Unitized Wheel, 532, 4-1/2 in x 1/2 in x 7/8 in, 7000047219

5 × $23.24 -

×

3M 91004, E-A-R, Soft Yellow Neons One Touch Refill Earplugs 391-1004, Uncorded, Regular Size, 2000 Pair/Case, 7000002305

1 × $244.68

3M 91004, E-A-R, Soft Yellow Neons One Touch Refill Earplugs 391-1004, Uncorded, Regular Size, 2000 Pair/Case, 7000002305

1 × $244.68 -

×

Dynabrade 58900 4-1/2" Dia. Compact Rebel Right Angle Depressed Center Wheel Grinder

2 × $1,331.00

Dynabrade 58900 4-1/2" Dia. Compact Rebel Right Angle Depressed Center Wheel Grinder

2 × $1,331.00 -

×

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10 -

×

Dynabrade 64354 26" x 36" (660 mm W x 914 mm L) Metal Capture Downdraft Station, 460 V (AC)

1 × $17,693.66

Dynabrade 64354 26" x 36" (660 mm W x 914 mm L) Metal Capture Downdraft Station, 460 V (AC)

1 × $17,693.66 -

×

Dynabrade 56581 Grip-Housing Teal

1 × $29.53

Dynabrade 56581 Grip-Housing Teal

1 × $29.53 -

×

Dynabrade 15057 Belt Guard

1 × $25.63

Dynabrade 15057 Belt Guard

1 × $25.63 -

×

Dynabrade 47802 .4 hp Right Angle Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $744.00

Dynabrade 47802 .4 hp Right Angle Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $744.00 -

×

Dynabrade 46001 .4 hp Right Angle Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

1 × $767.00

Dynabrade 46001 .4 hp Right Angle Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

1 × $767.00 -

×

Standard Abrasives 855853, GP Plus Wheel, 12 in x 2 in x 5 in 10S FIN, 7010368577

1 × $320.57

Standard Abrasives 855853, GP Plus Wheel, 12 in x 2 in x 5 in 10S FIN, 7010368577

1 × $320.57 -

×

Standard Abrasives 898008, Buff and Blend Combi-Wheel, 3 in x 2 in x 1/4 in A MED 60, 7000122259

5 × $29.42

Standard Abrasives 898008, Buff and Blend Combi-Wheel, 3 in x 2 in x 1/4 in A MED 60, 7000122259

5 × $29.42 -

×

Dynabrade 01486 Felt Silencer

1 × $2.07

Dynabrade 01486 Felt Silencer

1 × $2.07 -

×

Dynabrade 52574 4" (102 mm) Dia. Straight-Line Cut-Off Wheel Tool, Rear Exhaust, 1 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $633.00

Dynabrade 52574 4" (102 mm) Dia. Straight-Line Cut-Off Wheel Tool, Rear Exhaust, 1 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $633.00 -

×

Dynabrade 51926 Vane Set (4pk)

1 × $29.53

Dynabrade 51926 Vane Set (4pk)

1 × $29.53 -

×

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,067.00

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,067.00 -

×

ACS Diamond Cloth Belt, CX1250 3/8" X 120" 125U

16 × $27.50

ACS Diamond Cloth Belt, CX1250 3/8" X 120" 125U

16 × $27.50 -

×

Dynabrade 01564 Air Control Ring

1 × $13.02

Dynabrade 01564 Air Control Ring

1 × $13.02 -

×

Dynabrade 92738 2" W x 150' L 15 Micron A/O Microfinishing Film DynaCut Roll

1 × $133.01

Dynabrade 92738 2" W x 150' L 15 Micron A/O Microfinishing Film DynaCut Roll

1 × $133.01 -

×

Dynabrade 52986 3/8" Drill, .4 HP, Rear Exhaust, 500 RPM

1 × $980.00

Dynabrade 52986 3/8" Drill, .4 HP, Rear Exhaust, 500 RPM

1 × $980.00 -

×

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53

Standard Abrasives 881135, A/O Unitized Wheel, 811, 3 in x 1/4 in x 1/4 in, 7000121938

$12.05

Factory Stock, 7-10 Day Leadtime

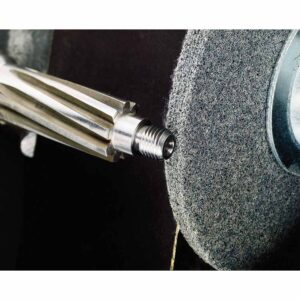

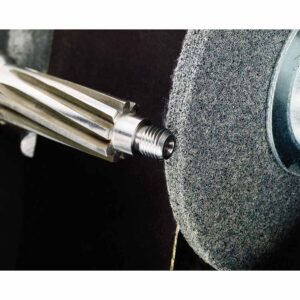

Our Standard Abrasives Aluminum Oxide 800 Series Unitized Wheel is a hard density wheel designed with extra tough edge durability, making it a good match for heavy-duty edge deburring and stainless steel polishing applications.

Hard Density Abrasive Wheel Removes Challenging Burrs with Precision and Imparts a Fine Polish

Our Standard Abrasives Aluminum Oxide 800 Series Unitized Wheel is offered in two grades of aluminum oxide (A/O) mineral: coarse or medium. The hardness of this wheel places it on the upper end of the spectrum of aggressiveness among Standard Abrasives Unitized Wheels. Given the coarseness of the mineral and the greater density, this wheel is able to withstand high-pressure applications and cut aggressively, making it well-suited for deburring and polishing applications.

Use our Standard Abrasives 800 Series Unitized Wheel for deburring stainless steel pipe thread, wire edges from surgical instruments, stainless steel sinks, tanks and other equipment for the food service industry. It is a prime choice for deburring gears and aircraft wing spars, and breaking edges on aluminum extrusions. When it comes to polishing, trust the 800 Series A/O Unitized Wheel to effectively polish stainless steel rule dies, welds on stainless steel sinks, machined surfaces, hand tools and round tubing.

Compatible with a Variety of Tools

Unitized wheels are typically used on a die grinder. A benefit of unitized wheels is that they are bi-directional and can be mounted on a tool or pedestal grinder without regard to the direction of the spindle rotation. This means the Standard Abrasives Unitized Wheel can be used with a variety of tools, and regardless of which way the workpiece is fed through the machine, the wheel will be able to respond, giving operators more flexibility. The stiffness of the unitized construction enables operators to use thinner wheels to access awkward angles with grinding tools.

Series 800 wheels comes in a range of diameters from 1-6″ and requires a unitized wheel mandrel (sold separately) for attachment to the tool. Quick change wheels are also available (sold separately).

Non-Woven Unitized Construction Offers a Step Up in Density and Durability for Stubborn Surfaces

Standard Abrasives Unitized Wheels are a great match for tough deburring, cleaning, blending and finishing applications. They come in a broad range of densities and grades to suit different metals, the degree of aggressiveness required, shape of the part, and desired finish. Although used for some of the same tasks as Standard Abrasives Buff and Blend products, they are designed with a far stronger and denser construction to support more aggressive applications and accomplish material removal more rapidly. Even though unitized wheels are much stiffer products, the non-woven nylon fibers of the wheel maintain the advantage of responding to surface irregularities while preserving the geometry of the piece, and produce a consistent finish.

Unitized wheels are created by starting with layers of open web material that combines non-woven fiber strands and abrasive mineral with a tough resin bond. These layers of web are then cured and compressed together. By fusing layers of open web, the abrasive gains more toughness and durability, so it can withstand repeated wear.

Ultimately, the wheel’s durability is what makes it such a good match for edges. Regardless of the diameter or thickness of the wheel, it maintains its structural integrity to remain a stiff and long-lasting abrasive even under high pressure. Additionally, as the layers wear, the wheel can be dressed to maintain its shape.

Load-Resistance Boosts Life and Performance

Standard Abrasives Unitized Wheels are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives Non-Woven Products

Standard Abrasives Unitized Wheels offer many benefits for heavy-duty jobs. For all the aforementioned reasons, Standard Abrasives Unitized Wheels invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput.