-

×

3M 45557, Cubitron ll Cloth Belt 784F, 60+ YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010299100, 50 per case

50 × $9.53

3M 45557, Cubitron ll Cloth Belt 784F, 60+ YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010299100, 50 per case

50 × $9.53 -

×

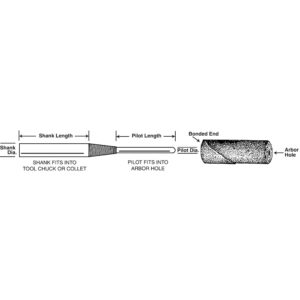

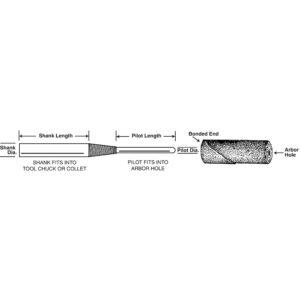

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32 -

×

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88 -

×

3M 08981, Scotch-Weld Epoxy Adhesive DP105, Clear, 48.5 mL Duo-Pak, 7100148733, 12/case

12 × $27.25

3M 08981, Scotch-Weld Epoxy Adhesive DP105, Clear, 48.5 mL Duo-Pak, 7100148733, 12/case

12 × $27.25 -

×

3M 88892, PSA Cloth Disc 348D, 60 X-weight, 15 in x NH, Die 1500A, 7010360718

20 × $13.07

3M 88892, PSA Cloth Disc 348D, 60 X-weight, 15 in x NH, Die 1500A, 7010360718

20 × $13.07 -

×

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Standard Abrasives 872199, Quick Change TR A/O Unitized Wheel, 721, 2 in x 1/4 in, 7010368348

10 × $6.72

Standard Abrasives 872199, Quick Change TR A/O Unitized Wheel, 721, 2 in x 1/4 in, 7010368348

10 × $6.72 -

×

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67 -

×

3M 96673, Glass Cloth Tape 398FR, White, 3 in x 36 yd, 7 mil, 7000001301

12 × $105.74

3M 96673, Glass Cloth Tape 398FR, White, 3 in x 36 yd, 7 mil, 7000001301

12 × $105.74 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 48236, General Purpose Glass Cloth Tape 3615, White, 2 in x 36 yd, 7 mil, 3615, 7000123894

24 × $96.42

3M 48236, General Purpose Glass Cloth Tape 3615, White, 2 in x 36 yd, 7 mil, 3615, 7000123894

24 × $96.42 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

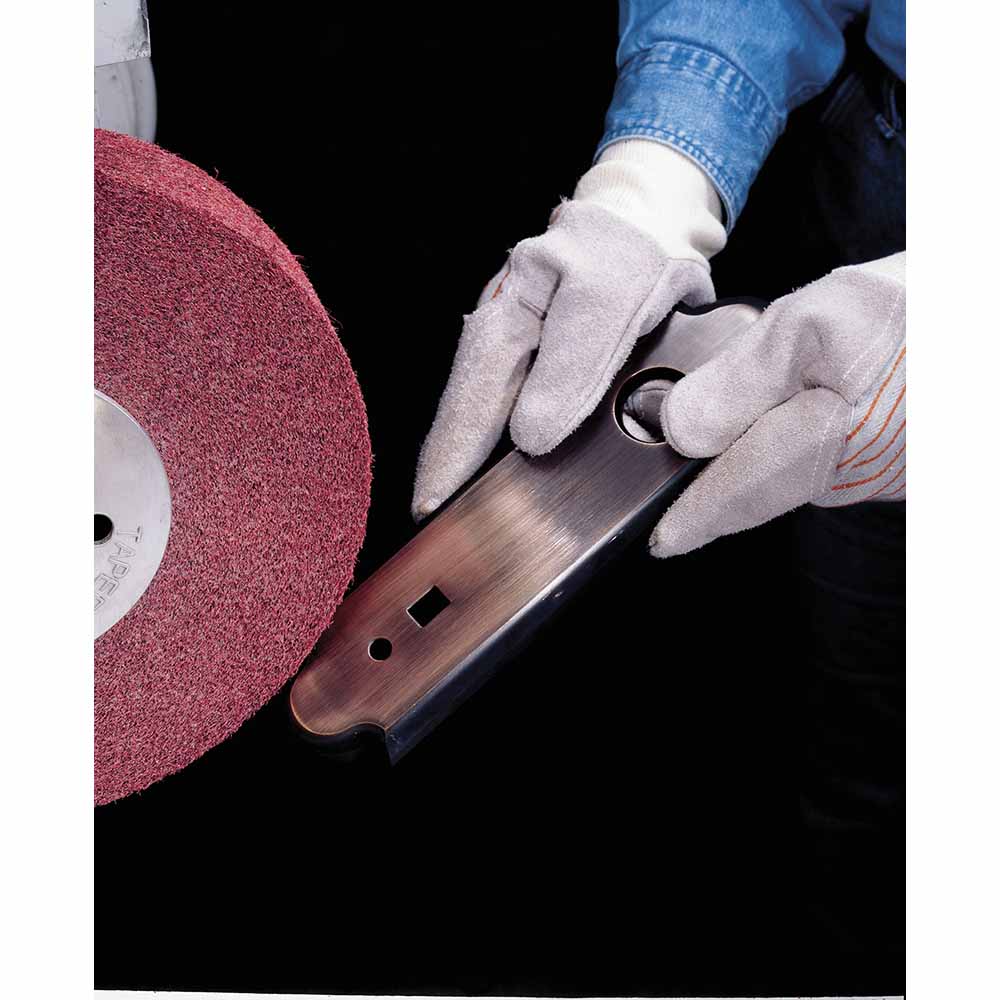

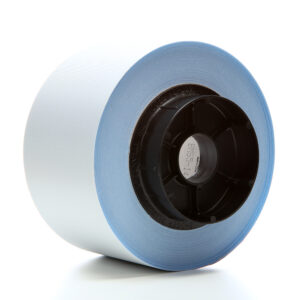

Producing Fine Finishes

Whether a technical requirement or purely aesthetic, many industrial markets value a final finish on their workpieces. We engineered our Standard Abrasives™ Metal Finishing Wheel to help produce the finishes users hope to achieve. It’s a good match for stainless steel fabricators and appliance and food equipment manufacturers, because it can help with production finishing of a variety of parts. Typical workpieces may include door hardware, plumbing fixtures, aluminum extrusions, sanitary metal containers and dairy equipment.

The Benefits of Aluminum Oxide

To engineer our Standard Abrasives™ Metal Finishing Wheel, we mix aluminum oxide mineral and nonwoven nylon fibers with resin to create an open web. Often, the mineral is paired with ferrous metals and composites, as well as fiberglass and plastic. It cuts aggressively without gouging or marring the substrate, maintaining original part geometry and reducing the need for rework. Medium grade aluminum oxide imparts decorative satin and antique finishes on stainless steel, brass and aluminum.

Dense and Durable

The nonwoven nylon fibers in the open web break down while finishing, exposing new mineral for a consistent cut. Moreover, gaps between the fibers allow swarf to escape, so the web resists clogging with debris, prolonging abrasive service life. Open web on the Metal Finishing Wheel is densely and compactly wound around a fiberglass core. The dense and durable construction helps the abrasive withstand greater contact pressures and speed variations. Additionally, the wheel edge can also be dressed to match part geometry if required. Combining aluminum oxide mineral with a dense convolute wheel constructions makes for a tough durable cutting wheel that requires minimal pressure. Moreover, the wheel’s density helps it stay firm and not deflect or yield to the substrate, so it performs well on flat surfaces and edges.

Altogether, our Standard Abrasives™ Metal Finishing Wheel is a durable and long lasting finishing wheel. It has the strength and toughness required to stand up to edges and extrusions but still leaves a soft, fine finish in its wake.