-

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16 -

×

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

3M 26109, PPS Series 2.0 Adapter, Type S23, 1/4 Female, 18 Thread NPS, 7100135941

4 × $25.96

3M 26109, PPS Series 2.0 Adapter, Type S23, 1/4 Female, 18 Thread NPS, 7100135941

4 × $25.96 -

×

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14

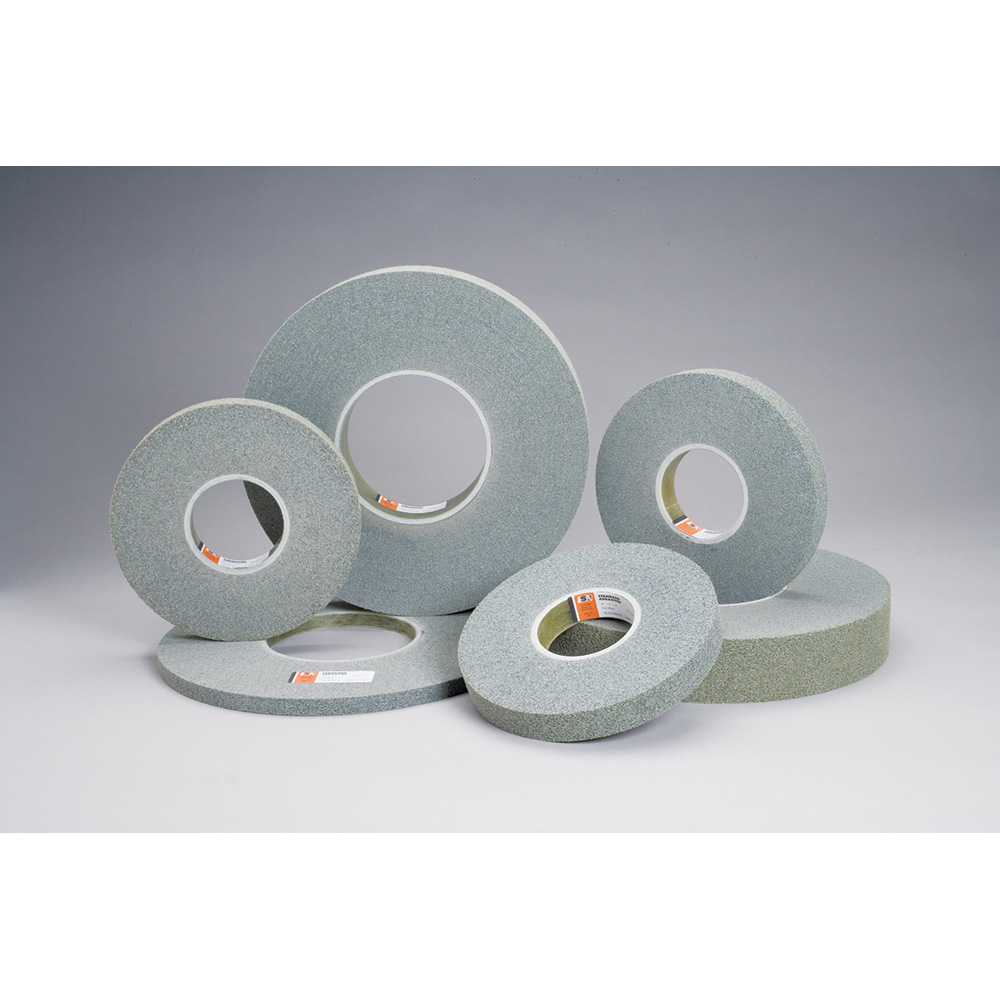

Standard Abrasives 853333, LDW Wheel 8 in x 1 in x 3 in 8S FIN, 7010301237

$111.35

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.