-

×

3M 05528, Scotch-Brite Roloc Surface Conditioning Disc, TR, 05528, 2 in x NH A CRS, 7000000752, 200 per case

200 × $1.35

3M 05528, Scotch-Brite Roloc Surface Conditioning Disc, TR, 05528, 2 in x NH A CRS, 7000000752, 200 per case

200 × $1.35 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

2 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

2 × $18,352.22 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97 -

×

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56 -

×

3M 16236, PPS Spray Gun Holder, Single Gun, 7100152679

5 × $99.23

3M 16236, PPS Spray Gun Holder, Single Gun, 7100152679

5 × $99.23 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

3M 66630, Cloth Belt 341D, 50 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118864, 20 per case

20 × $11.98

3M 66630, Cloth Belt 341D, 50 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118864, 20 per case

20 × $11.98 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56 -

×

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

3M 45188, Stikit Disc Hand Pad, 5 in x 1/8 in, 7100015524

20 × $7.52

3M 45188, Stikit Disc Hand Pad, 5 in x 1/8 in, 7100015524

20 × $7.52 -

×

3M 66626, Cloth Belt 341D, 50 X-weight, 4 in x 36 in, Fabri-lok, Single-flex, 7010308385, 25 per case

25 × $6.86

3M 66626, Cloth Belt 341D, 50 X-weight, 4 in x 36 in, Fabri-lok, Single-flex, 7010308385, 25 per case

25 × $6.86 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

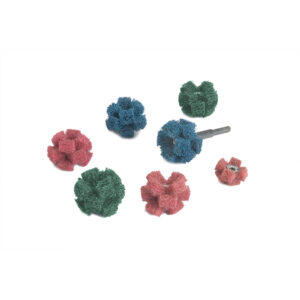

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

50 × $3.75

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

50 × $3.75 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.70

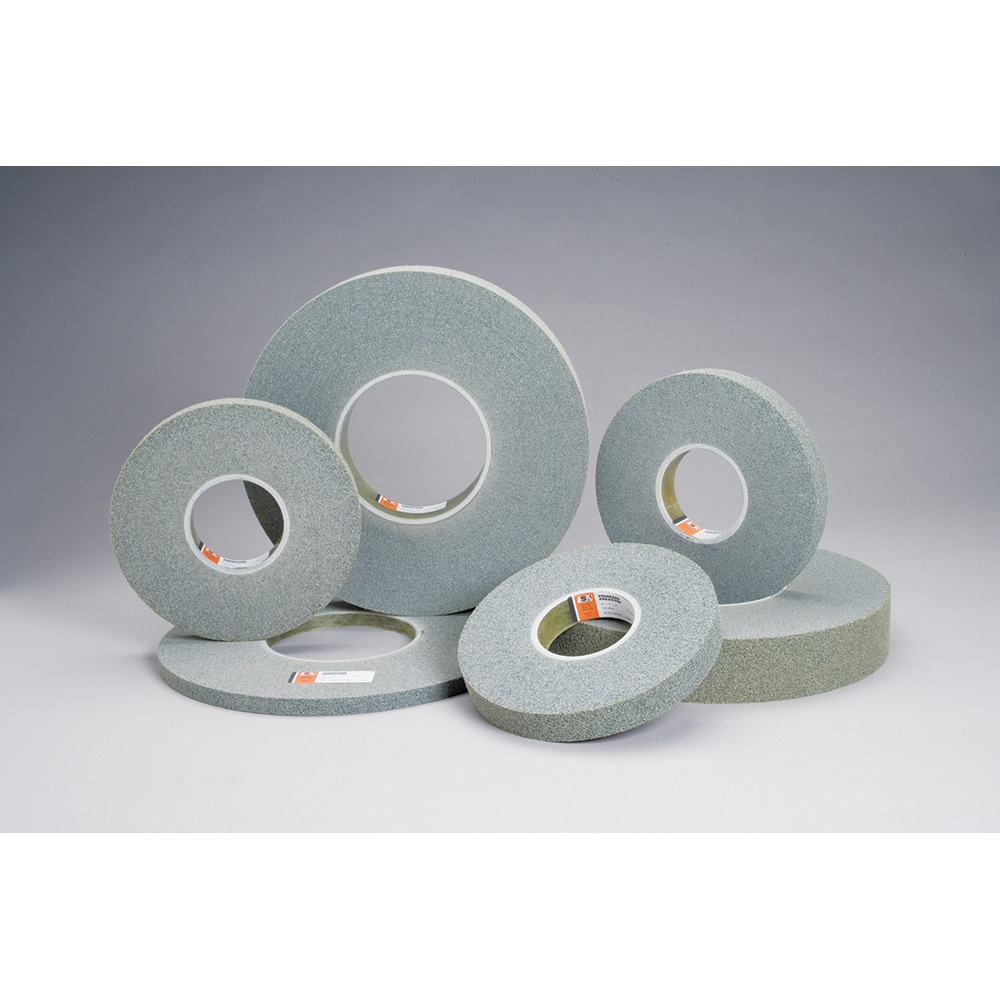

Standard Abrasives 852033, LDW Wheel 6 in x 1/2 in x 1 in 7S FIN, 7010310153

$65.94

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.