-

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $699.72 -

×

Dynabrade 79174 2" W x 30" L 80 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91

Dynabrade 79174 2" W x 30" L 80 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15 -

×

Dynabrade 61203 RaptorVac Pneumatic DrumVac Kit, Single Operator, For Use With Tools

1 × $2,276.15

Dynabrade 61203 RaptorVac Pneumatic DrumVac Kit, Single Operator, For Use With Tools

1 × $2,276.15 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

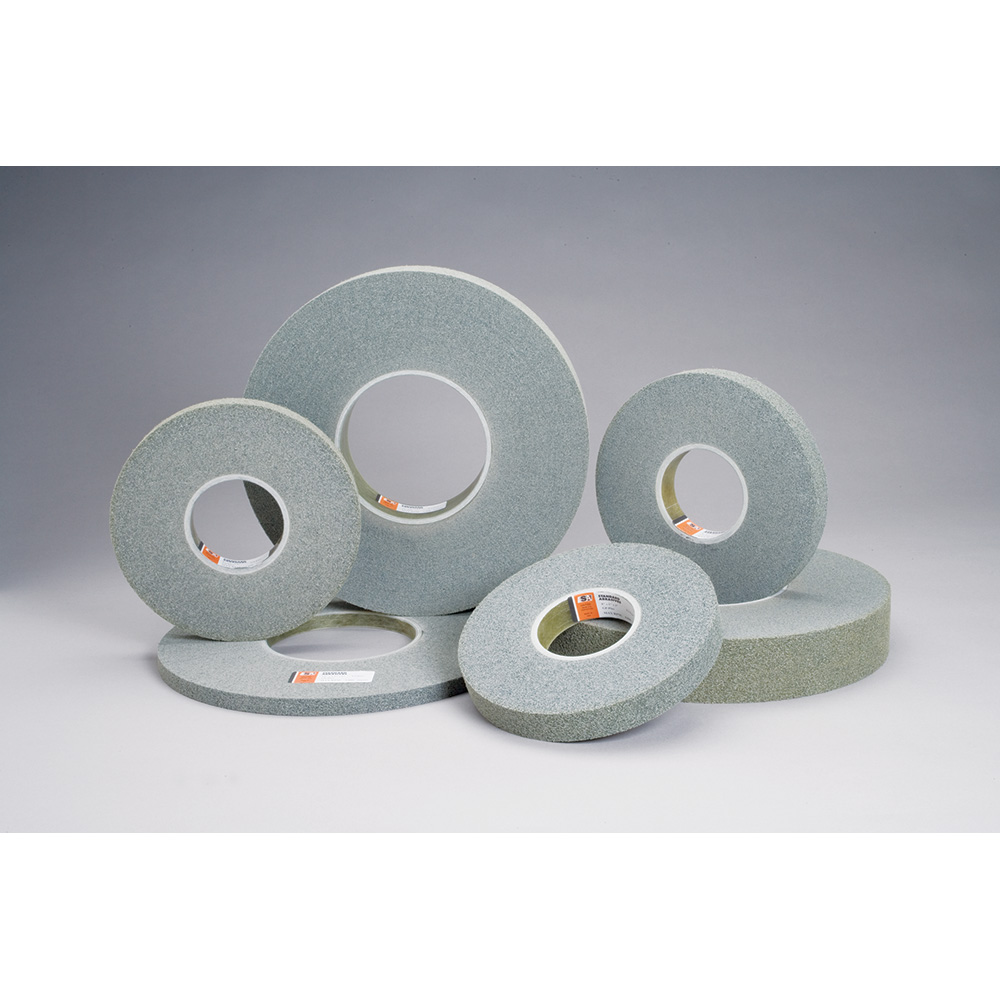

Standard Abrasives 851133, LDW Wheel, 6 in x 1 in x 1 in 6S FIN, 7000047105

$86.54

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.