-

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

100 × $1.70

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

100 × $1.70 -

×

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

50 × $2.97

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

50 × $2.97 -

×

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

50 × $1.79

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

50 × $1.79 -

×

Dynabrade 58500 3" W x 4-1/4" L Dynabug II Orbital Sander, Non-Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $250.00

Dynabrade 58500 3" W x 4-1/4" L Dynabug II Orbital Sander, Non-Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $250.00 -

×

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

50 × $9.14

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

50 × $9.14 -

×

Dynabrade 54705 Rotor/Vane Set

1 × $118.01

Dynabrade 54705 Rotor/Vane Set

1 × $118.01 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

120 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

120 × $11.64 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70

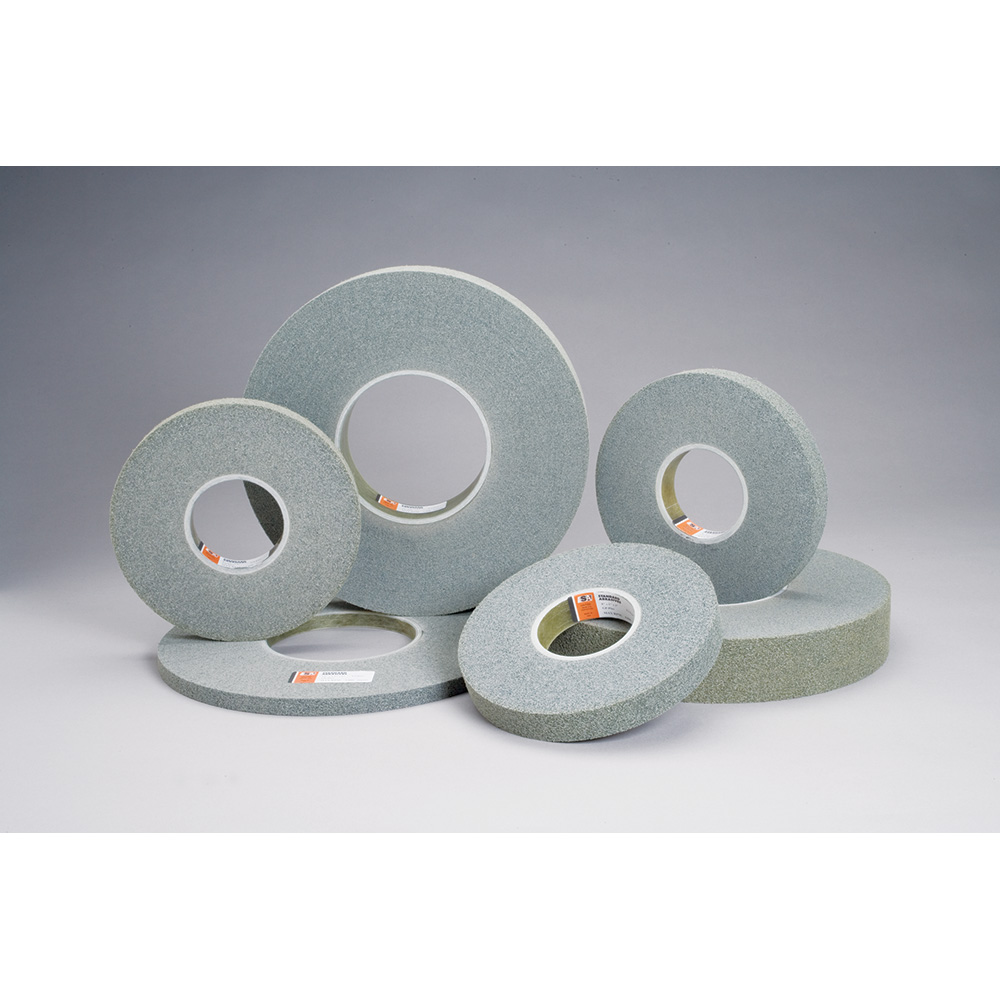

Standard Abrasives 851133, LDW Wheel, 6 in x 1 in x 1 in 6S FIN, 7000047105

$86.54

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.