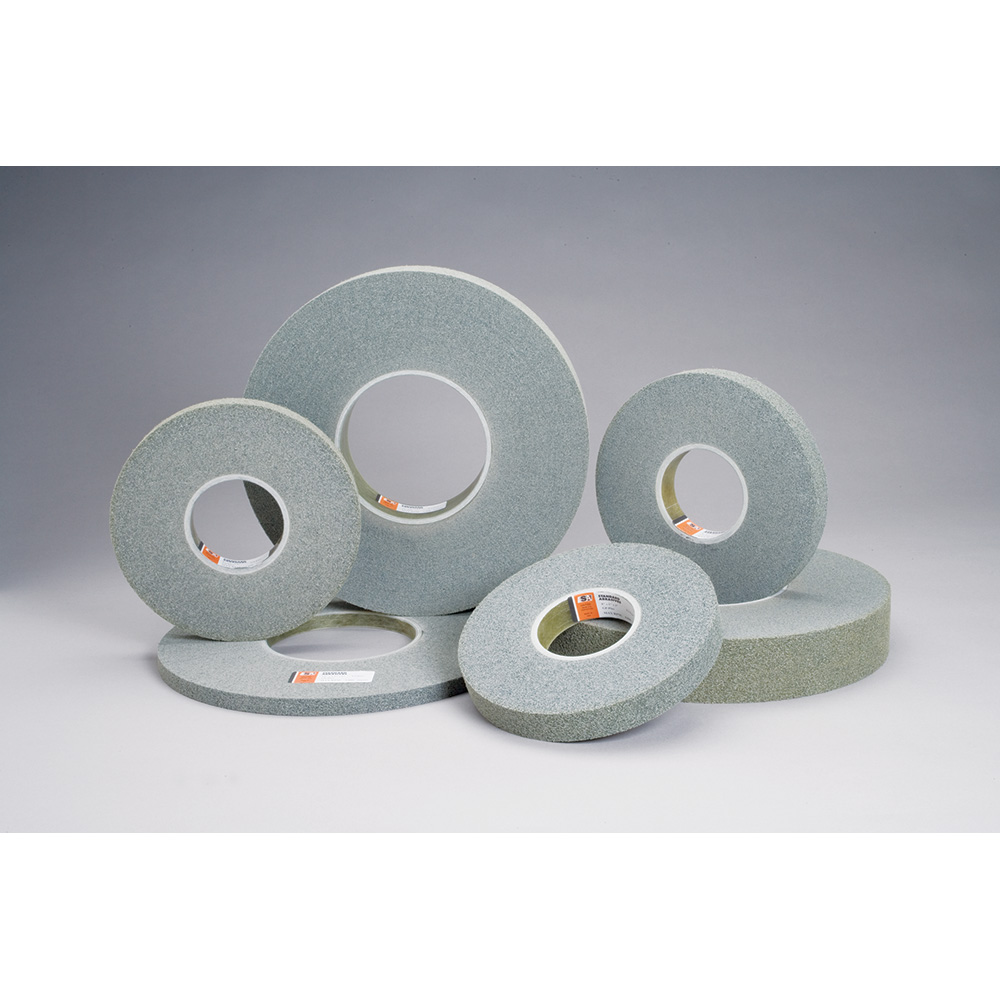

Standard Abrasives 851133, LDW Wheel, 6 in x 1 in x 1 in 6S FIN, 7000047105

$86.54

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack  Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack