-

×

Dynabrade 94476 Replacement Rubber Tip

1 × $10.31

Dynabrade 94476 Replacement Rubber Tip

1 × $10.31 -

×

Dynabrade 94435 - 3-1/4" Dia. x 7" W Pneumatic Tire

1 × $132.65

Dynabrade 94435 - 3-1/4" Dia. x 7" W Pneumatic Tire

1 × $132.65 -

×

Dynabrade 93906 3" Dia. Continuous Rim Diamond Mounted Cut-Off Wheel

1 × $236.62

Dynabrade 93906 3" Dia. Continuous Rim Diamond Mounted Cut-Off Wheel

1 × $236.62 -

×

Dynabrade 92248 4" Dia. x 1/2" W Bent Coarse Wire Wheel

2 × $48.52

Dynabrade 92248 4" Dia. x 1/2" W Bent Coarse Wire Wheel

2 × $48.52 -

×

Dynabrade 59182 6" Dia. Dynorbital-Spirit Random Orbital Sander, Central Vacuum, 3/16" Orbit

1 × $240.00

Dynabrade 59182 6" Dia. Dynorbital-Spirit Random Orbital Sander, Central Vacuum, 3/16" Orbit

1 × $240.00 -

×

Dynabrade 58506 3-7/8" W x 5-5/8" L Dynabug II Orbital Sander, Central Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $263.00

Dynabrade 58506 3-7/8" W x 5-5/8" L Dynabug II Orbital Sander, Central Vacuum, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $263.00 -

×

Dynabrade 92201 1-1/2" W x 30" L 60 Grit A/Z DynaCut Belt, 50/pack

100 × $5.80

Dynabrade 92201 1-1/2" W x 30" L 60 Grit A/Z DynaCut Belt, 50/pack

100 × $5.80 -

×

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

72 × $4.82

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

72 × $4.82 -

×

Dynabrade 15336 Rubber Drive Wheel

1 × $76.45

Dynabrade 15336 Rubber Drive Wheel

1 × $76.45 -

×

Dynabrade DAQ6 6" Dia. National Detroit Dual-Action Sander, Non-Vacuum

1 × $466.00

Dynabrade DAQ6 6" Dia. National Detroit Dual-Action Sander, Non-Vacuum

1 × $466.00 -

×

Dynabrade 15006 Mini-Dynafile II Abrasive Belt Tool Versatility Kit

1 × $829.00

Dynabrade 15006 Mini-Dynafile II Abrasive Belt Tool Versatility Kit

1 × $829.00 -

×

Dynabrade 13502 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 1/2" (13 mm) Dia. Arbor

1 × $996.00

Dynabrade 13502 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 1/2" (13 mm) Dia. Arbor

1 × $996.00 -

×

3M 53697, Scotch High Tack Box Sealing Tape 373+, Clear, 48 mm x 100 m, 36 Rolls/Case, 7100266182

36 × $10.62

3M 53697, Scotch High Tack Box Sealing Tape 373+, Clear, 48 mm x 100 m, 36 Rolls/Case, 7100266182

36 × $10.62 -

×

Dynabrade 11682 Dynabelter Contact Arm Assembly, 4 Inch Dia x 1/2 Inch, 70 Durometer, Wheel Radiused

1 × $402.12

Dynabrade 11682 Dynabelter Contact Arm Assembly, 4 Inch Dia x 1/2 Inch, 70 Durometer, Wheel Radiused

1 × $402.12 -

×

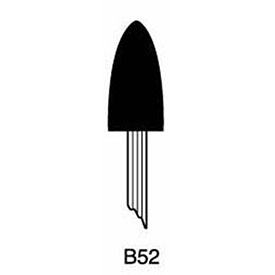

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.57

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.57 -

×

3M 92751, Scotch Box Lock Shipping Tape 3950-4-SRM, 1.88 in x 54.6 yd (48 mm x 50 m), 7100253404

4 × $24.73

3M 92751, Scotch Box Lock Shipping Tape 3950-4-SRM, 1.88 in x 54.6 yd (48 mm x 50 m), 7100253404

4 × $24.73 -

×

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27 -

×

Dynabrade 11231 Contact Arm Ass'y, 3/4" Dia. x 1/2" W, Rubber Wheel, with 1/2" W Platen

1 × $73.36

Dynabrade 11231 Contact Arm Ass'y, 3/4" Dia. x 1/2" W, Rubber Wheel, with 1/2" W Platen

1 × $73.36 -

×

Dynabrade 91315 11-1/4" Dia. x 36 Grit A/O Non-Vacuum Hook-Face DynaCut Disc, 10/Box

10 × $10.04

Dynabrade 91315 11-1/4" Dia. x 36 Grit A/O Non-Vacuum Hook-Face DynaCut Disc, 10/Box

10 × $10.04 -

×

Dynabrade 93534 3" Mandrel for Sanding Stars, 3-48 Male Thread

1 × $9.90

Dynabrade 93534 3" Mandrel for Sanding Stars, 3-48 Male Thread

1 × $9.90 -

×

Dynabrade 96005 - 1/4" Male Plug with 3/8" NPT Male Thread

1 × $10.83

Dynabrade 96005 - 1/4" Male Plug with 3/8" NPT Male Thread

1 × $10.83 -

×

Dynabrade 56354 2-2/3" x 6-7/8" Non-Vacuum Dynabug II Disc Pad, Vinyl-Face

1 × $33.57

Dynabrade 56354 2-2/3" x 6-7/8" Non-Vacuum Dynabug II Disc Pad, Vinyl-Face

1 × $33.57 -

×

3M 60894, Impact Stripping Tape 500, Green, 1 in x 10 yd, 36 mil, 9 Rolls/Case, 7000001170

9 × $28.01

3M 60894, Impact Stripping Tape 500, Green, 1 in x 10 yd, 36 mil, 9 Rolls/Case, 7000001170

9 × $28.01 -

×

Dynabrade 07107 Vane Set (5pk)

1 × $33.82

Dynabrade 07107 Vane Set (5pk)

1 × $33.82

Standard Abrasives 840909, Buff and Blend GP Disc, 8 in x 1/2 in A FIN, 7010330836

$4.96

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend GP Disc is a versatile non-woven abrasive disc designed to lightly blend, clean, deburr and finish a variety of metals.

Moderately Aggressive for Lighter-Weight Applications

Our Standard Abrasives™ Buff and Blend GP Disc is a great multi-purpose product for general-duty industrial applications. One of five Buff and Blend materials, the maroon GP material is moderately aggressive. Use it to remove light oxidation, blend minor surface imperfections, clean surfaces prior to coatings, remove small burrs, and perform basic equipment cleanup. A flexible open web conforms to workpiece contours, radii and internal diameters. Its non-woven construction makes the disc spongy and responsive. If desired, discs may be ganged on a shaft to form a wheel and accommodate larger workpieces. When the job requires a tougher disc for higher-pressure applications, we recommend using a Standard Abrasives™ Buff and Blend HP or HS Disc. Quick change discs are also available.

Options to Suit Many Different Surfaces

Versatile and multi-purpose, Standard Abrasives™ Buff and Blend GP Disc comes in a range of minerals, grades and sizes to suit many different applications. It works well on a variety of substrates, including ferrous and non-ferrous metals, aluminum, high nickel/chrome alloys and stainless steel.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Buff and Blend non-woven products offer many benefits. Varying Buff and Blend materials help distinguish Buff and Blend products from each other, but all Buff and Blend products have an open web. The open web combines abrasive mineral and non-woven nylon fibers with a resin-reinforced bond. The resin bond securely anchors mineral to the fibers, making for a strong, durable abrasive.

Gaps between fibers allow swarf to escape, so the abrasive does not get clogged with debris. Minimizing swarf and debris prolongs abrasive service life and keeps minerals cutting sharper for longer. Nylon fibers won’t splinter during grinding, offering a good alternative to steel wool. Moreover, as the fibers break down and fresh mineral is exposed, it reduces the likelihood of the disc smearing the surface. Standard Abrasives™ Buff and Blend products deliver a consistent cut and finish – part after part.