-

×

3M 29902, Sanding Screen, 150 Grit, 12 in x 18 in, 7100160763

20 × $4.84

3M 29902, Sanding Screen, 150 Grit, 12 in x 18 in, 7100160763

20 × $4.84 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

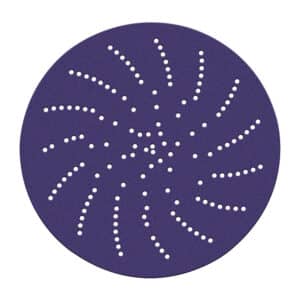

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51 -

×

3M 08367, Urethane Seam Sealer, Black, 310 mL Cartridge, 7000119968, 12 per case

12 × $26.40

3M 08367, Urethane Seam Sealer, Black, 310 mL Cartridge, 7000119968, 12 per case

12 × $26.40 -

×

3M 914, DISC PAD HOLDER , 4 IN X 1/8 IN X 3/8 IN 1/2-13 INTERNAL, 7010365096

1 × $31.71

3M 914, DISC PAD HOLDER , 4 IN X 1/8 IN X 3/8 IN 1/2-13 INTERNAL, 7010365096

1 × $31.71 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 62602, Scotch-Weld Threadlocker TL22, Purple, 50 mL Bottle, 7100039159, 10/case

10 × $42.72

3M 62602, Scotch-Weld Threadlocker TL22, Purple, 50 mL Bottle, 7100039159, 10/case

10 × $42.72 -

×

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59 -

×

3M 04297 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Very Fine, 2 in x 132 in, 7010365859

5 × $51.26

3M 04297 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Very Fine, 2 in x 132 in, 7010365859

5 × $51.26 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

2 × $734.00 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00 -

×

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle,Straight, 7000031879

24 × $172.73 -

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Standard Abrasives 724277, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 2 Ply x 8-32, 7010368699

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.