-

×

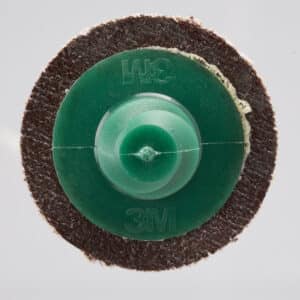

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65 -

×

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46 -

×

3M 26597, Cloth Belt 341D, P320 X-weight, 1 in x 42 in, Film-lok, Single-flex, 7010294511, 200 per case

400 × $2.14

3M 26597, Cloth Belt 341D, P320 X-weight, 1 in x 42 in, Film-lok, Single-flex, 7010294511, 200 per case

400 × $2.14 -

×

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15 -

×

3M 69602, Cloth Belt 777F, 60 YF-weight, 1 in x 11 in, Sine-lok, Full-flex, 7010295223, 500 per case

500 × $1.05

3M 69602, Cloth Belt 777F, 60 YF-weight, 1 in x 11 in, Sine-lok, Full-flex, 7010295223, 500 per case

500 × $1.05 -

×

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40 -

×

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

400 × $3.47

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

400 × $3.47 -

×

3M 93200 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 3/4 in x 18 in, 7000028521

20 × $12.17

3M 93200 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 3/4 in x 18 in, 7000028521

20 × $12.17 -

×

3M 09615 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Coarse, 1/2 in x 24 in, 7010328566

20 × $10.82

3M 09615 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Coarse, 1/2 in x 24 in, 7010328566

20 × $10.82 -

×

3M 18088 Scotch-Brite SE Surface Conditioning Belt, SE-BS, A/O Coarse, 1/2 in x 24 in, 7000046006

20 × $10.82

3M 18088 Scotch-Brite SE Surface Conditioning Belt, SE-BS, A/O Coarse, 1/2 in x 24 in, 7000046006

20 × $10.82 -

×

Dynabrade 79522 1/2" W x 24" L Premium Very Fine Plus NWN DynaBrite Belt, 10/pack

10 × $8.28

Dynabrade 79522 1/2" W x 24" L Premium Very Fine Plus NWN DynaBrite Belt, 10/pack

10 × $8.28 -

×

3M 05783 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 3 in x 10-11/16 in, 7000045880

10 × $16.50

3M 05783 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 3 in x 10-11/16 in, 7000045880

10 × $16.50 -

×

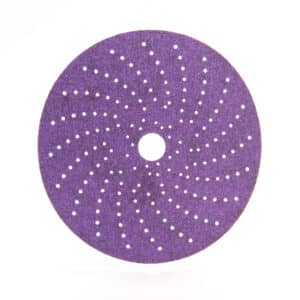

3M 31381, Cubitron II Hookit Marine Sanding Abrasive Disc 737U, 31381, 6 in, 120+, 7100062433

80 × $19.02

3M 31381, Cubitron II Hookit Marine Sanding Abrasive Disc 737U, 31381, 6 in, 120+, 7100062433

80 × $19.02 -

×

Standard Abrasives 32929, PSA A/O Disc, 709607, 1/2 in x NH, 120, 7100037906

100 × $0.09

Standard Abrasives 32929, PSA A/O Disc, 709607, 1/2 in x NH, 120, 7100037906

100 × $0.09 -

×

3M 69436, Cloth Belt 577F, 120 YF-weight, 1/2 in x 24 in, Fabri-lok, Single-flex, 7000119456, 200 per case

200 × $1.57

3M 69436, Cloth Belt 577F, 120 YF-weight, 1/2 in x 24 in, Fabri-lok, Single-flex, 7000119456, 200 per case

200 × $1.57 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

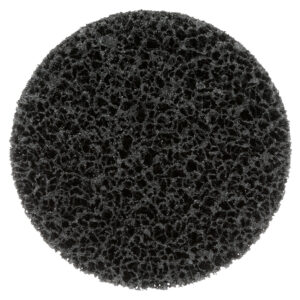

3M 18424, Scotch-Brite Coating Removal Disc, CR-DH, SiC Extra Coarse, 4-1/2 in x NH, 7000046011

20 × $11.24

3M 18424, Scotch-Brite Coating Removal Disc, CR-DH, SiC Extra Coarse, 4-1/2 in x NH, 7000046011

20 × $11.24 -

×

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71 -

×

Dynabrade 78595 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 80 Grit, 100/pack

100 × $0.61

Dynabrade 78595 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 80 Grit, 100/pack

100 × $0.61 -

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.52

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.52

3M 94927, Scotch-Brite EXL PRO Deburring Wheel, EP-WL, 10S Fine, 8 in x 1/2 in x 3 in, 7100062983

$76.27

Factory Stock, 7-10 Day Leadtime

The Scotch-Brite EXL PRO Deburring Wheel is our highest performing deburring wheel and an ideal fit for off-hand operations. It provides 30-50% longer life than our original EXL wheel, without sacrificing a smooth feel and conformability. Designed for optimal operator comfort, the EXL PRO wheel requires less pressure for a faster cut, making this the wheel of choice for premium performance.