-

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

2 × $533.42

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

2 × $533.42 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

3 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

3 × $1,585.00 -

×

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

24 × $4.03

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

24 × $4.03 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00 -

×

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23

3M 29851, Sanding Screen, 100 Grit, 15 in x NH, 7100160814

12 × $5.23 -

×

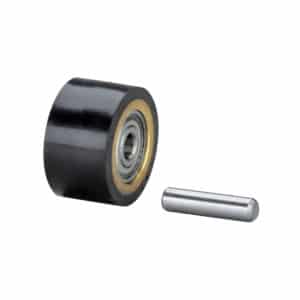

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

2 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

2 × $385.42 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $1,721.00 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

Dynabrade 11069 Contact Wheel, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

1 × $26.17

Dynabrade 11069 Contact Wheel, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

1 × $26.17 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00 -

×

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90 -

×

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

Dynabrade 11072 Contact Wheel Ass'y, 7/16" Dia. x 1/8" W x 3/8" I.D., Crown Face, Brass

1 × $35.33

Dynabrade 11072 Contact Wheel Ass'y, 7/16" Dia. x 1/8" W x 3/8" I.D., Crown Face, Brass

1 × $35.33 -

×

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00 -

×

Dynabrade 11282 Contact Wheel Ass'y, 3/4" Dia. x 5/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $42.43

Dynabrade 11282 Contact Wheel Ass'y, 3/4" Dia. x 5/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $42.43 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

Dynabrade 11088 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $43.79

Dynabrade 11088 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $43.79 -

×

3M 29836, Sanding Screen, 60 Grit, 18 in x NH, 7100160820

12 × $11.06

3M 29836, Sanding Screen, 60 Grit, 18 in x NH, 7100160820

12 × $11.06 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00 -

×

Dynabrade 11305 Contact Arm Ass'y, 3/8" Dia. x 1" W, 40 Duro

1 × $90.75

Dynabrade 11305 Contact Arm Ass'y, 3/8" Dia. x 1" W, 40 Duro

1 × $90.75 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

3M 29911, Scotch-Brite Roloc+ Clean and Strip XT Pro Disc, XO-ZR, SiC Extra Coarse, TR+, Purple, 4 in x 1/2 in, 7100176127

$15.80

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Roloc+ Clean and Strip XT Pro Disc features silicon carbide abrasive mineral incorporated into an open nylon web. It effectively removes rust, paint, mill scale, coatings and adhesives from surfaces without significantly altering the base material. The high-strength fibers are highly conformable, resist chunking and loading, and perform well on edges.