-

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35 -

×

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50 -

×

Dynabrade 15006 Mini-Dynafile II Abrasive Belt Tool Versatility Kit

1 × $789.82

Dynabrade 15006 Mini-Dynafile II Abrasive Belt Tool Versatility Kit

1 × $789.82 -

×

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01 -

×

Dynabrade 12205 Stockade Reciprocating Saw, .4 HP, 2,400 SPM

1 × $1,285.74

Dynabrade 12205 Stockade Reciprocating Saw, .4 HP, 2,400 SPM

1 × $1,285.74 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

Dynabrade 15003 Mini-Dynafile II Abrasive Belt Tool

1 × $680.48

Dynabrade 15003 Mini-Dynafile II Abrasive Belt Tool

1 × $680.48 -

×

Insize HDT-LP200-D15, IMPACT DEVICE D+15, 6940561948424

1 × $618.18

Insize HDT-LP200-D15, IMPACT DEVICE D+15, 6940561948424

1 × $618.18 -

×

Dynabrade 91315 11-1/4" Dia. x 36 Grit A/O Non-Vacuum Hook-Face DynaCut Disc, 10/Box

10 × $9.37

Dynabrade 91315 11-1/4" Dia. x 36 Grit A/O Non-Vacuum Hook-Face DynaCut Disc, 10/Box

10 × $9.37 -

×

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95 -

×

Dynabrade 98273 - 1/2" Female Coupler with 1/2" Male Plug Assembly

1 × $84.53

Dynabrade 98273 - 1/2" Female Coupler with 1/2" Male Plug Assembly

1 × $84.53 -

×

Dynabrade 90226 1/4" W x 18" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 90226 1/4" W x 18" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Insize 6282-2011, EXTENSION ROD, 6928640362941

1 × $5.83

Insize 6282-2011, EXTENSION ROD, 6928640362941

1 × $5.83 -

×

Insize 1150-2000E, DIGITAL HEIGHT GAGE, 0-80"/0-2000mm, 6928640355363

1 × $4,575.00

Insize 1150-2000E, DIGITAL HEIGHT GAGE, 0-80"/0-2000mm, 6928640355363

1 × $4,575.00 -

×

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $488.06

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $488.06 -

×

Dynabrade 91429 1/2" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 91429 1/2" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,639.98

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,639.98 -

×

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94 -

×

3M 07333, Impact Resistant Structural Adhesive, 200 mL Cartridge, 7100050351, 3 percase

3 × $75.75

3M 07333, Impact Resistant Structural Adhesive, 200 mL Cartridge, 7100050351, 3 percase

3 × $75.75 -

×

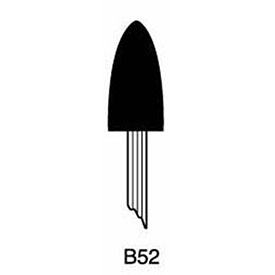

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93

3M 29259, Scotch-Brite Metal Finishing Unitized Wheel, 6 in x 1 in x 1 in 5A MED, 7100074494

Discontinued, 3M Suggested Replacement-

| 7100003943 |

Our Scotch-Brite Metal Finishing Unitized Wheel combines the durability of cured open web with fast yet soft cutting action, rendering it a good wheel for finishing, blending and polishing, especially on hard-to-reach areas.

Good for Finishing, Blending and Polishing

The Scotch-Brite™ Metal Finishing Unitized Wheel is engineered by layering open web material, comprised of non-woven nylon fibers, aluminum oxide and resin, and compressing it. The compression enhances overall abrasive durability; it strengthens the wheel’s ability to swiftly and effectively tackle tough blending applications. Aluminum oxide mineral interspersed throughout the open web cuts sharp but leaves a fine, soft finish. Together, these attributes make Scotch-Brite™ Metal Finishing Unitized Wheel a good match for finishing, blending and polishing.

Typical applications for this Scotch-Brite™ wheel might include weld cleaning and blending in stainless steel tanks, finishing and blending builders hardware and generating a grained finish after weld blending. Unitized wheels may be used to blend and match #3 or #4 mill finishes on stainless steel and to create brushed or satin finishes on cutlery. On softer metals such as aluminum, copper and brass, they are used to blend out minor surface imperfections and handling marks while providing a decorative finish.

Durable and Aggressive

Customers choose Scotch-Brite™ wheels because of their ease of use and consistent results. Available in convolute and unitized designs, each of these wheel types offers unique benefits. Metal finishing unitized wheels offer the same finishing capability of metal finishing convolute wheel. However, the layered construction of unitized wheels makes them more aggressive and durable, slightly less conformable than convolute wheels. Additionally, unitized wheels are non-directional, so they can run clockwise or counterclockwise. The “edge” of the web becomes the cutting side, and the wheel is used with tools like inline sanders, bench motors, backstands and die grinders.

Scotch-Brite™ Unitized Wheel performance differences can be attributed to mineral (aggressiveness) and density (hardness). The combination of these two characteristics and subtle variations determine if the wheel will cut more aggressively or will be more durable and less conformable. Depending on their application, users can select the right combination for their unique project needs. Our Scotch-Brite™ Metal Finishing Unitized Wheels are available in small diameters and narrow widths. In essence, they provide durability and value for finishing of parts that are too narrow, tight or small to finish efficiently with wider width wheels, so you can still tackle those tough areas and achieve a fine finish.