-

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

3 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

3 × $1,569.00 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

3 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

3 × $109.23 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00 -

×

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94 -

×

3M 34555, Cubitron II Net Sheet Roll, 240+, 80 mm x 10 m, 7100247339, 6 Rolls/Case

6 × $31.57

3M 34555, Cubitron II Net Sheet Roll, 240+, 80 mm x 10 m, 7100247339, 6 Rolls/Case

6 × $31.57 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

2 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

2 × $385.42 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

Dynabrade 91166 1/2" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

100 × $1.95

Dynabrade 91166 1/2" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

100 × $1.95 -

×

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.71

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.71 -

×

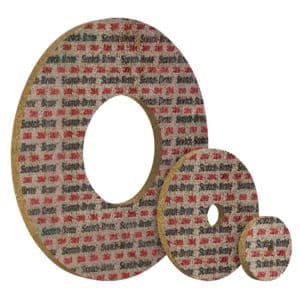

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48 -

×

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.68

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.68 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.10

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.10 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

3M 21538, Scotch-Brite Roloc Clean and Strip XT Pro Disc, XO-DR, SiC Extra Coarse, TR, Purple, 2 in, Die Q200P, 7100175521

$4.36

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Roloc Clean and Strip XT Pro Disc features silicon carbide abrasive mineral incorporated into an open nylon web. It effectively removes rust, paint, mill scale, coatings and adhesives from surfaces without significantly altering the base material. The high-strength fibers are highly conformable, resist chunking and loading, and perform well on the edges of a workpiece.