-

×

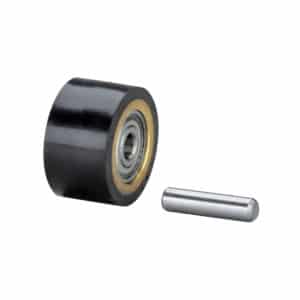

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 11069 Contact Wheel, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

3 × $26.17

Dynabrade 11069 Contact Wheel, 7/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, 70 Duro Rubber

3 × $26.17 -

×

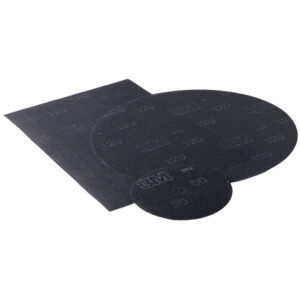

3M 29844, Sanding Screen, 120 Grit, 16 in x NH, 7100160823

12 × $5.17

3M 29844, Sanding Screen, 120 Grit, 16 in x NH, 7100160823

12 × $5.17 -

×

Dynabrade 11376 Big Wheel, 4-3/8 Dia. x 1/4" W x 5/8 I.D., Urethane

1 × $287.76

Dynabrade 11376 Big Wheel, 4-3/8 Dia. x 1/4" W x 5/8 I.D., Urethane

1 × $287.76 -

×

3M 29882, Sanding Screen, 220 Grit, 18 in x NH, 7100160813

12 × $4.84

3M 29882, Sanding Screen, 220 Grit, 18 in x NH, 7100160813

12 × $4.84 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08

Dynabrade 11068 Contact Wheel Ass'y, 5/16" Dia. x 3/8" W x 1/4" I.D., Crown Face, Steel

1 × $46.08 -

×

3M 29821, Sanding Screen, 150 Grit, 20 in x NH, 7100160254

12 × $7.52

3M 29821, Sanding Screen, 150 Grit, 20 in x NH, 7100160254

12 × $7.52 -

×

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90

Dynabrade 11074 Contact Wheel Ass'y, 5/8" Dia. x 1/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $32.90 -

×

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60 -

×

Dynabrade 11352 Contact Wheel Ass'y, 5/16" Dia. x 5/8" W x 1/4" I.D., Crown Face, Steel

2 × $79.92

Dynabrade 11352 Contact Wheel Ass'y, 5/16" Dia. x 5/8" W x 1/4" I.D., Crown Face, Steel

2 × $79.92 -

×

Dynabrade 11090 Contact Wheel Assy, 5/8 Dia. x 3/8 W x 3/8 I.D., Crown Face, 70 Duro Rubber

1 × $64.27

Dynabrade 11090 Contact Wheel Assy, 5/8 Dia. x 3/8 W x 3/8 I.D., Crown Face, 70 Duro Rubber

1 × $64.27 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49 -

×

3M 29881, Sanding Screen, 220 grit 17 in x NH, 220 Grit, 7100160816

12 × $4.92

3M 29881, Sanding Screen, 220 grit 17 in x NH, 220 Grit, 7100160816

12 × $4.92 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91 -

×

Dynabrade 11088 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $43.79

Dynabrade 11088 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $43.79 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48

3M 21538, Scotch-Brite Roloc Clean and Strip XT Pro Disc, XO-DR, SiC Extra Coarse, TR, Purple, 2 in, Die Q200P, 7100175521

$4.36

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Roloc Clean and Strip XT Pro Disc features silicon carbide abrasive mineral incorporated into an open nylon web. It effectively removes rust, paint, mill scale, coatings and adhesives from surfaces without significantly altering the base material. The high-strength fibers are highly conformable, resist chunking and loading, and perform well on the edges of a workpiece.