-

×

Standard Abrasives 873273, S/C Unitized Wheel, 732, 6 in x 1/4 in x 1/2 in, 7010301203

10 × $37.04

Standard Abrasives 873273, S/C Unitized Wheel, 732, 6 in x 1/4 in x 1/2 in, 7010301203

10 × $37.04 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35 -

×

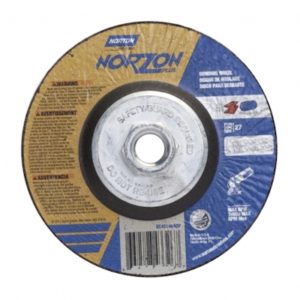

Norton 66252843323 - 4 -1/2" X 1/8" X 5/8" Center Hub, NORZON PLUS Type 27 Depressed Center Cut Off And Grinding Wheel, 10 Each

10 × $11.00

Norton 66252843323 - 4 -1/2" X 1/8" X 5/8" Center Hub, NORZON PLUS Type 27 Depressed Center Cut Off And Grinding Wheel, 10 Each

10 × $11.00 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

Dynabrade 77794 4-1/2" Dia. x 7/8" Center Hole, 80 Grit, Type 29, Ceramic DynaCut Flap Disc, 10/pack

10 × $5.92

Dynabrade 77794 4-1/2" Dia. x 7/8" Center Hole, 80 Grit, Type 29, Ceramic DynaCut Flap Disc, 10/pack

10 × $5.92 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

400 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

400 × $1.61 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87 -

×

3M 76900, Cloth Belt 340D, 50 X-weight, 37 in x 60 in, Film-lok, Single-flex, 7010361975, 3 per case

3 × $51.11

3M 76900, Cloth Belt 340D, 50 X-weight, 37 in x 60 in, Film-lok, Single-flex, 7010361975, 3 per case

3 × $51.11 -

×

Insize 3352-50A, HIGH PRECISION DIGITAL BLADE MICROMETERS/SNAP GAGE (with data interface), 25-50mm/1-2", .0002mm/.00001", 6940561982176

1 × $1,207.00

Insize 3352-50A, HIGH PRECISION DIGITAL BLADE MICROMETERS/SNAP GAGE (with data interface), 25-50mm/1-2", .0002mm/.00001", 6940561982176

1 × $1,207.00 -

×

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 20852, Scotch-Weld Epoxy Adhesive 2216, Translucent, Part B/A, 1 Pint Kit, 7010310194, 6/case

6 × $230.32

3M 20852, Scotch-Weld Epoxy Adhesive 2216, Translucent, Part B/A, 1 Pint Kit, 7010310194, 6/case

6 × $230.32 -

×

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42 -

×

Insize 7232, SCRIBER, 6928640320088

1 × $7.01

Insize 7232, SCRIBER, 6928640320088

1 × $7.01 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,639.98

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,639.98 -

×

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

60 × $6.67

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

60 × $6.67

3M 18485, Scotch-Brite Coating Removal Disc, 7 in x NH S XCS Bulk, 7000120884

$22.26

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Coating Removal Disc features extra coarse (XCS) silicon carbide mineral to effectively remove paint and rust from metal surfaces and welds. Together with the conformable, non-woven material, silicon carbide abrasives remove coatings without gouging, undercutting, or damaging the base material, especially on hard surfaces.

The Layer Beneath: Coating Removal

Our Scotch-Brite Coating Removal Disc is a great match for coating removal applications, primarily because the open web responds so well to surface irregularities and contours. The web is springy and responsive, and when it comes to coating removal ? keeping part geometry intact is key. We engineered this disc, because we know that coating removal is about gently unearthing the surface that lies beneath, so you can make it new again.

We incorporated extra coarse (XCS) silicon carbide mineral in the Scotch-Brite Coating Removal Disc. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep. While the mineral breaks down faster than aluminum oxide, it produces a brighter finish. As the mineral is extra coarse, it will cut more aggressively than lighter grades, helping peel back the unwanted layer.

Hook and Loop Attachment for Enhanced Productivity

The coating removal disc also has a Hook and Loop backing, which helps expedite tool attachment and enhance productivity. These loops attach securely to hooks on a hook and loop backup pad (sold separately), and the backup pad attaches to the power tool.

The Many Benefits of Scotch-Brite Abrasives

Nonwoven technology makes our Scotch-Brite industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.