-

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.53 -

×

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

100 × $3.75

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

100 × $3.75 -

×

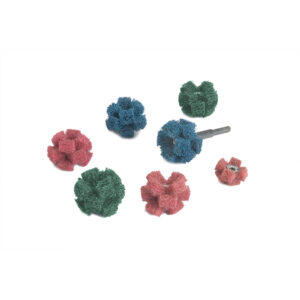

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

25 × $6.64

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

25 × $6.64 -

×

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45 -

×

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

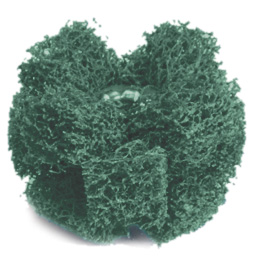

Standard Abrasives 727396, Buff and Blend Cross Buff HS, A/O Medium, 2 in x 1/2 in x 2 Ply x 8-32, 7000122101

$5.84

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Buff and Blend Cross Buff HS is uniquely designed to clean and polish hard-to-reach areas like the internal diameters of pipes and tubing. The Buff & Blend HS material allows removing surface contaminants without eliminating critical detail or gouging the workpiece.

Unique Design for Tight Spots

The Standard Abrasives™ Buff and Blend Cross Buff HS is our go-to product for stubborn surface areas that require a unique, tough construction. While discs or wheels may be unable to get inside a narrow pipe or tube, our Cross Buff HS was designed to do just that. The abrasive fingers are spring-like and bend and move to accommodate the inner diameter of the workpiece. They refine deep scratches and defects without compromising the geometry of the part.

Quality Materials for the Toughest Jobs

Our Buff & Blend High Strength products are made from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain. The durable high strength construction of our mounted cross buff provides aggressive action for the toughest applications and provides greater tear resistance, perfect for deburring or final finishing on irregularly shaped parts in tight spaces.

The abrasive material on the Cross Buff HS is a strong, all-purpose material for tough cleaning and polishing jobs. The aluminum oxide mineral cuts sharp while still delivering a fine polish. Cross Buff HS comes in both coarse and medium grades. Typically, a medium grade is useful when a soft scratch pattern is desired, whereas a coarse grade delivers a more aggressive scratch. Given its versatility, this abrasive is well-suited for removing surface oxidation, rust and surface coatings for part inspection, as well as surface preparation prior to coating. It can help remove corrosion on Steel Rule and Kirksite dies. It’s also great for polishing round and square tubing, valve spools, molds, dies and inside diameters of lifter bores, valve bodies and brake cylinders.

Open Web Design

In addition to the unique design of the Standard Abrasives™ Buff and Blend Cross Buff HS, the open web construction also adds a level of sponginess and flexibility. This open web material is created by combining nonwoven nylon strands and abrasive mineral with resin bonding material. Gaps between the nylon fibers allow unwanted swarf to escape, enhancing load resistance and efficiency. As the abrasive is less likely to clog with debris, the mineral keeps cutting sharper, longer.

The open web material resin bonding are also waterproof and can be used with lubricants, which help to keep the abrasive running cool and wash away swarf. The load-resistant properties of the web, combined with the swarf-cleaning action of the lubricant, help to prevent workpiece contamination. As debris clears away, the likelihood of particles smearing or blemishing the substrate decreases.