-

×

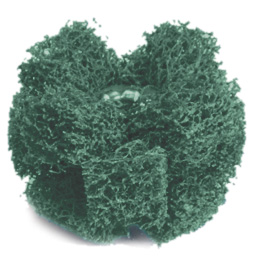

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75 -

×

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

2 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

2 × $4.57 -

×

3M 24339, Scotch-Brite EXL Unitized Wheel, XL-UW, 3S Fine, 6 in x 1/4 in x 1 in, SPR 20888A, 7010365120

8 × $28.15

3M 24339, Scotch-Brite EXL Unitized Wheel, XL-UW, 3S Fine, 6 in x 1/4 in x 1 in, SPR 20888A, 7010365120

8 × $28.15 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

3M 00550, DynatronAuto Seam Sealer Caulk, 550, Grey, 12 oz, 7000125068, 12 per case

12 × $16.71

3M 00550, DynatronAuto Seam Sealer Caulk, 550, Grey, 12 oz, 7000125068, 12 per case

12 × $16.71 -

×

3M 01032, Scotch-Brite Clean and Strip Unitized Wheel, CS-UW, 7S Extra Coarse, 6 in x 1 in x 5/8 in, 7000120867

2 × $111.05

3M 01032, Scotch-Brite Clean and Strip Unitized Wheel, CS-UW, 7S Extra Coarse, 6 in x 1 in x 5/8 in, 7000120867

2 × $111.05 -

×

3M 05744, Hookit Hand File Board, 2-3/4 in x 16 in, 7000045717

1 × $73.94

3M 05744, Hookit Hand File Board, 2-3/4 in x 16 in, 7000045717

1 × $73.94 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 30u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 30u

12 × $7.60 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60 -

×

3M 29821, Sanding Screen, 150 Grit, 20 in x NH, 7100160254

12 × $7.52

3M 29821, Sanding Screen, 150 Grit, 20 in x NH, 7100160254

12 × $7.52 -

×

3M 35827, Hookit Dust Extraction Flexible Sanding Block, 273 mm x 67 mm, 7100256623

12 × $44.04

3M 35827, Hookit Dust Extraction Flexible Sanding Block, 273 mm x 67 mm, 7100256623

12 × $44.04 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

3M 36876, Self-Stick Liquid Protection Fabric, Blue, 4 in x 300 ft perroll, 7100169348, 6 Rolls Per Pack

1 × $534.33

3M 36876, Self-Stick Liquid Protection Fabric, Blue, 4 in x 300 ft perroll, 7100169348, 6 Rolls Per Pack

1 × $534.33 -

×

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45

Refine Surfaces

While discs or wheels may be unable to get inside a narrow pipe or tube, our Standard Abrasives™ Buff and Blend Cross Buff GP was designed to do just that. The abrasive fingers are spring-like and bend and move to accommodate the inner diameter of the workpiece. They refine the surface while maintaining the geometry of the part.

The abrasive material on Cross Buff GP is a great all-purpose material for cleaning and polishing. The mineral cuts sharp while still delivering a fine polish. Cross Buff GP comes in a range of grades from very fine (VFN) to coarse (CRS). Typically, very fine and fine grades are useful when a soft scratch pattern is desired, whereas a medium or coarse grade delivers a more aggressive scratch. Given its versatility, this abrasive is well-suited for removing surface oxidation, rust and surface coatings for part inspection, as well as surface preparation prior to coating. It can help remove corrosion on Steel Rule and Kirksite dies. It’s also great for polishing round and square tubing, valve spools, molds, dies and inside diameters of lifter bores, valve bodies and brake cylinders.

Attachment Styles

Standard Abrasives™ Buff and Blend Cross Buff GP fasten to a mandrel that in turn can be fastened to the power tool. The cross buffs attach to the mandrel with their 8-32 or 1/4-20 thread options. These versatile attachment options make it easier to securely mount and fasten the buff to the tool, helping to increase productivity.

Benefits of Open Web Abrasives

_In addition to the unique design of the Standard Abrasives™ Buff and Blend Cross Buff GP, the open web construction also adds a level of sponginess and flexibility. This open web material is created by combining nonwoven nylon strands and abrasive mineral with resin. Gaps between the nylon fibers allow unwanted swarf to escape, enhancing load resistance. As the abrasive is less likely to clog with debris, the mineral keeps cutting sharper, longer.

The open web material is waterproof and may be used with lubricants, which help to keep the abrasive running cool and wash away swarf. The load-resistant properties of the web, combined with the swarf-cleaning action of the lubricant, help to prevent workpiece contamination. As debris clears away, the likelihood of the disc smearing or blemishing the substrate decreases.