-

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 87103, Cloth Belt 341D, 24 X-weight, 9 in x 20 in, Fabri-lok, Single-flex, 7010326200, 20 per case

20 × $18.86

3M 87103, Cloth Belt 341D, 24 X-weight, 9 in x 20 in, Fabri-lok, Single-flex, 7010326200, 20 per case

20 × $18.86 -

×

3M 50199, Finesse-it Hand Sanding Pad, 1-1/4 in, Soft Black Vinyl Face, 7000028401

20 × $10.24

3M 50199, Finesse-it Hand Sanding Pad, 1-1/4 in, Soft Black Vinyl Face, 7000028401

20 × $10.24 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

3M 70994, Scotch-Weld Acrylic Adhesive DP8410NS, Green, 45 mL Duo-Pak, 7100024055,12/case

12 × $14.25

3M 70994, Scotch-Weld Acrylic Adhesive DP8410NS, Green, 45 mL Duo-Pak, 7100024055,12/case

12 × $14.25 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

3M 28719, Wheel Adapter Kit 28719, 1 in x 5/8-11 Internal, 7100050705

1 × $50.70

3M 28719, Wheel Adapter Kit 28719, 1 in x 5/8-11 Internal, 7100050705

1 × $50.70 -

×

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32 -

×

Dynabrade 98269 1/2" Female Coupler

1 × $56.65

Dynabrade 98269 1/2" Female Coupler

1 × $56.65 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

Dynabrade 52380 4" (102 mm) Dia. Straight-Line Type 1 Extension Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $910.00

Dynabrade 52380 4" (102 mm) Dia. Straight-Line Type 1 Extension Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $910.00 -

×

Insize ISY-600-800012, UNIVERSAL SUPPORT WITH DAMPING, 6940561980417

1 × $128.10

Insize ISY-600-800012, UNIVERSAL SUPPORT WITH DAMPING, 6940561980417

1 × $128.10 -

×

Dynabrade 55242 Vane Set (4pk)

1 × $38.19

Dynabrade 55242 Vane Set (4pk)

1 × $38.19 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

2 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

2 × $388.51 -

×

Dynabrade 54972 Vane Set (5pk)

1 × $48.62

Dynabrade 54972 Vane Set (5pk)

1 × $48.62 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42

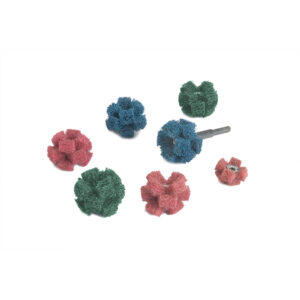

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.