-

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

3 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

3 × $192.76 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M 62816, Adhesive Sealant 760 UV, White, 600 mL Sausage Pack, 7000046609, 12/Case

12 × $26.69

3M 62816, Adhesive Sealant 760 UV, White, 600 mL Sausage Pack, 7000046609, 12/Case

12 × $26.69 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

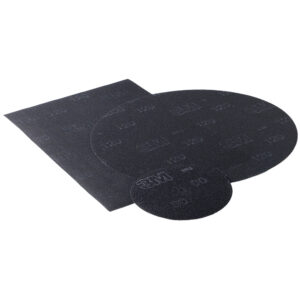

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 25,000RPM, 33425

1 × $975.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 25,000RPM, 33425

1 × $975.00 -

×

3M 16578, Accuspray ONE Spray Gun Kit, 7100096182

4 × $363.88

3M 16578, Accuspray ONE Spray Gun Kit, 7100096182

4 × $363.88 -

×

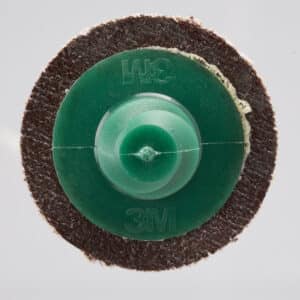

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80 -

×

Dynabrade 94993 1/4" Male Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $42.43

Dynabrade 94993 1/4" Male Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $42.43 -

×

3M 17534 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 2-1/2 in x 60 in, 7010366042

10 × $46.80

3M 17534 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 2-1/2 in x 60 in, 7010366042

10 × $46.80 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53 -

×

3M 16553, Scotch-Brite Extra Duty Hand Pad 6444, 6 in x 9 in, 7000028548, 60/Case

1 × $100.58

3M 16553, Scotch-Brite Extra Duty Hand Pad 6444, 6 in x 9 in, 7000028548, 60/Case

1 × $100.58 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $734.00 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 08025, Adhesive Sealant 740 UV, Black, 600 mL Sausage Pack, 7100057385, 12/Case

12 × $21.89

3M 08025, Adhesive Sealant 740 UV, Black, 600 mL Sausage Pack, 7100057385, 12/Case

12 × $21.89 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

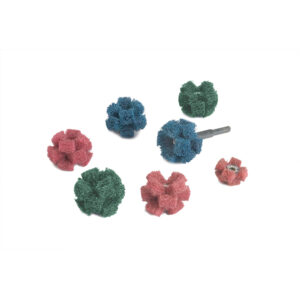

Standard Abrasives 260013, Cross Buff Kit 260013, 7000121667

5 × $58.18

Standard Abrasives 260013, Cross Buff Kit 260013, 7000121667

5 × $58.18

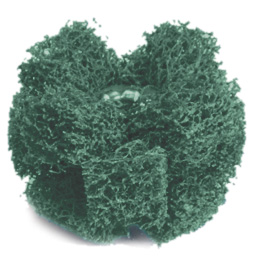

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.