-

×

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 29882, Sanding Screen, 220 Grit, 18 in x NH, 7100160813

12 × $4.84

3M 29882, Sanding Screen, 220 Grit, 18 in x NH, 7100160813

12 × $4.84 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,679.00 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

Dynabrade 95684 1/4" Male Coupler

1 × $26.80

Dynabrade 95684 1/4" Male Coupler

1 × $26.80 -

×

Dynabrade 95714 3/8" NPT Female 1/4" NPT Male

1 × $23.82

Dynabrade 95714 3/8" NPT Female 1/4" NPT Male

1 × $23.82 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 20908, PSA Cloth Disc 348D, P100 X-weight, 2 in x NH, Die 200P, 7000118874

200 × $0.74

3M 20908, PSA Cloth Disc 348D, P100 X-weight, 2 in x NH, Die 200P, 7000118874

200 × $0.74 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00 -

×

3M 67016, E-A-R, Soft Grippers Probed Test Plugs 393-2021-50, 50 Pair/Case, 7010341317

1 × $106.13

3M 67016, E-A-R, Soft Grippers Probed Test Plugs 393-2021-50, 50 Pair/Case, 7010341317

1 × $106.13 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

Dynabrade 51854 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $683.00

Dynabrade 51854 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $683.00 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25 -

×

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

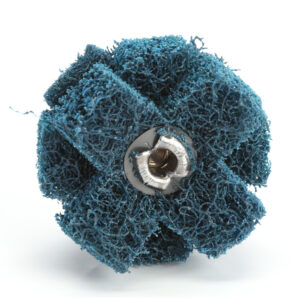

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.