-

×

Dynabrade 91163 3/8" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.60

Dynabrade 91163 3/8" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.60 -

×

3M 26583, Accuspray Refill Pack for PPS Series 2.0, Green, 1.3 mm, 7100152953

5 × $10.20

3M 26583, Accuspray Refill Pack for PPS Series 2.0, Green, 1.3 mm, 7100152953

5 × $10.20 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 64933, Scotch-Brite Pro Hand Pad, PO-HP, 1 - 6 in x 9 in pad 7447 PRO and 1 - 6 in x 9 in pad 7448 PRO, Multi-pack, 7100033494

20 × $4.62

3M 64933, Scotch-Brite Pro Hand Pad, PO-HP, 1 - 6 in x 9 in pad 7447 PRO and 1 - 6 in x 9 in pad 7448 PRO, Multi-pack, 7100033494

20 × $4.62 -

×

Standard Abrasives 827620, Buff and Blend HP Power Pad, 6 in x 9 in, A VFN, 7010310293, 50 ea/Case

1 × $190.45

Standard Abrasives 827620, Buff and Blend HP Power Pad, 6 in x 9 in, A VFN, 7010310293, 50 ea/Case

1 × $190.45 -

×

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96 -

×

Dynabrade 91427 1/4" W x 12" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91427 1/4" W x 12" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

2 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

2 × $25.96 -

×

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94 -

×

Insize 3108-1F, DIGITAL OUTSIDE MICROMETER, IP65, 0-1"/0-25mm, ratchet friction thimble, 6928640355493

1 × $168.96

Insize 3108-1F, DIGITAL OUTSIDE MICROMETER, IP65, 0-1"/0-25mm, ratchet friction thimble, 6928640355493

1 × $168.96 -

×

3M 05791, Hookit Pad, 7000028382

20 × $18.50

3M 05791, Hookit Pad, 7000028382

20 × $18.50 -

×

Dynabrade 91165 1/2" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.81

Dynabrade 91165 1/2" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.81 -

×

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71

3M 33439, Cubitron II File Belt, 33439, 60+, 10 mm x 330 mm (3/8 in x 13 in), 7100033194, 10 belts per carton, 5 cartons per case

50 × $23.71 -

×

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15

3M 35790, 675L, 1" X 120", 74u, Diamond Microfinishing Film Belts, 7010509196

2 × $97.15 -

×

3M 27468, EMI Copper Foil Shielding Tape 1181, 1 in x 18 yd (25,40 mm x 16,5 m), 7000132169

9 × $79.81

3M 27468, EMI Copper Foil Shielding Tape 1181, 1 in x 18 yd (25,40 mm x 16,5 m), 7000132169

9 × $79.81 -

×

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

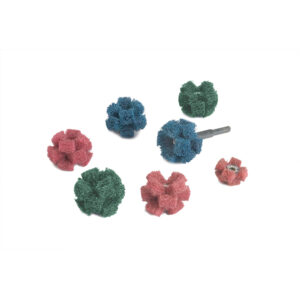

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57 -

×

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.