-

×

3M 01490, Stikit Gold Disc Roll, 8 in, P150, 7010292229, 125 discs per roll

4 × $167.94

3M 01490, Stikit Gold Disc Roll, 8 in, P150, 7010292229, 125 discs per roll

4 × $167.94 -

×

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47 -

×

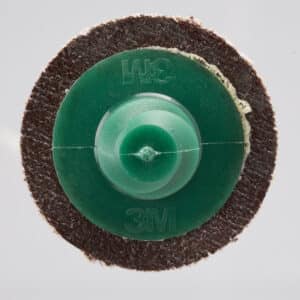

Dynabrade 92086 3" Dia. x 36 Grit Ceramic Non-Vacuum DynaCut Locking-Type Disc, 25/pack

25 × $2.75

Dynabrade 92086 3" Dia. x 36 Grit Ceramic Non-Vacuum DynaCut Locking-Type Disc, 25/pack

25 × $2.75 -

×

3M 20360, Scotch-Weld Epoxy Adhesive 2216, Gray, Part B, 5 Gallon Drum (Pail), 7000046360

5 × $509.65

3M 20360, Scotch-Weld Epoxy Adhesive 2216, Gray, Part B, 5 Gallon Drum (Pail), 7000046360

5 × $509.65 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,520.00 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

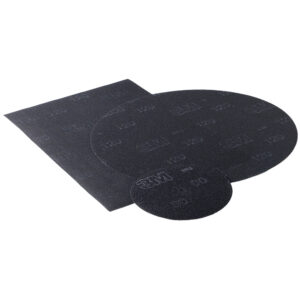

3M 07958, Sanding Screen, 80 Grit, 7-7/8 in x 3/16 in, 7100160277

40 × $2.21

3M 07958, Sanding Screen, 80 Grit, 7-7/8 in x 3/16 in, 7100160277

40 × $2.21 -

×

3M 16609, Accuspray Atomizing Head, Red, 2.0 mm, 7000045543 (4 Nozzles/Kit) (6 Kits/Case)

6 × $30.70

3M 16609, Accuspray Atomizing Head, Red, 2.0 mm, 7000045543 (4 Nozzles/Kit) (6 Kits/Case)

6 × $30.70 -

×

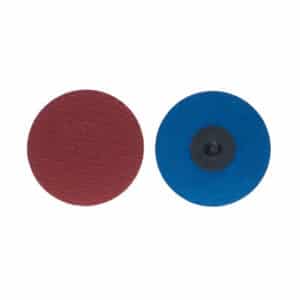

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

Dynabrade 61420 Raptor Vac Electric Portable Vacuum System

1 × $1,408.00

Dynabrade 61420 Raptor Vac Electric Portable Vacuum System

1 × $1,408.00 -

×

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65 -

×

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

3M 05444, Stikit Hand File Board, 2-3/4 in x 16 in, 7000045763

1 × $75.21

3M 05444, Stikit Hand File Board, 2-3/4 in x 16 in, 7000045763

1 × $75.21 -

×

3M 56788, Stacked Lens Cover FF-400-18, 7010385198

1 × $580.32

3M 56788, Stacked Lens Cover FF-400-18, 7010385198

1 × $580.32 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 79820 3" 220 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $35.37

Dynabrade 79820 3" 220 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $35.37 -

×

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.