-

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25 -

×

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23 -

×

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14 -

×

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.44

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.44 -

×

3M 98242, Marine Adhesive Sealant 3000 UV, Black, 290 mL Cartridge, 7100111111, 12/Case

12 × $13.17

3M 98242, Marine Adhesive Sealant 3000 UV, Black, 290 mL Cartridge, 7100111111, 12/Case

12 × $13.17 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

1000 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

1000 × $0.67 -

×

Insize 4808, WIRE GAGE, 0-36(.3249~.0050"), 6928640330155

1 × $33.19

Insize 4808, WIRE GAGE, 0-36(.3249~.0050"), 6928640330155

1 × $33.19 -

×

Insize 5022, 2-PIECE MEASURING TOOL SET, 6928640321290

1 × $206.22

Insize 5022, 2-PIECE MEASURING TOOL SET, 6928640321290

1 × $206.22 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11 -

×

Insize 7232, SCRIBER, 6928640320088

1 × $7.01

Insize 7232, SCRIBER, 6928640320088

1 × $7.01 -

×

3M 45020, Diamond Grade DG3 Reflective Digital Sheeting 4081UDS, Fluorescent Yellow, 30 in x 50 yd, 1 Roll/Case, 7100282390

1 × $2,038.81

3M 45020, Diamond Grade DG3 Reflective Digital Sheeting 4081UDS, Fluorescent Yellow, 30 in x 50 yd, 1 Roll/Case, 7100282390

1 × $2,038.81 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22 -

×

Insize 4102-181, STEEL GAGE BLOCK SET, 81pcs, grade AS-1, 6928640329906

2 × $695.78

Insize 4102-181, STEEL GAGE BLOCK SET, 81pcs, grade AS-1, 6928640329906

2 × $695.78 -

×

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96 -

×

3M 76625, Roloc Disc 777F, 80 YF-weight, TR, 1 in, Die R100N, 7000045621

500 × $0.62

3M 76625, Roloc Disc 777F, 80 YF-weight, TR, 1 in, Die R100N, 7000045621

500 × $0.62 -

×

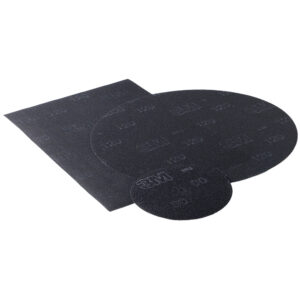

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

3M 20910, PSA Cloth Disc 348D, 60 X-weight, 2 in x NH, Die 200P, 7000118872

200 × $0.80

3M 20910, PSA Cloth Disc 348D, 60 X-weight, 2 in x NH, Die 200P, 7000118872

200 × $0.80 -

×

3M 95725, Venture Tape Metal Building Facing Tape 1552CW, White, 72 mm x 45.7 m, 7010313505

16 × $26.60

3M 95725, Venture Tape Metal Building Facing Tape 1552CW, White, 72 mm x 45.7 m, 7010313505

16 × $26.60 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Insize ISY-100-27018, SUPPORT HEAD, nylon, 6928640393808

1 × $15.24

Insize ISY-100-27018, SUPPORT HEAD, nylon, 6928640393808

1 × $15.24 -

×

Insize 0120-IM24, INDUCTIVE MOISTURE METER, 0~100%, 6974029776588

1 × $207.68

Insize 0120-IM24, INDUCTIVE MOISTURE METER, 0~100%, 6974029776588

1 × $207.68 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 64324, Foil Tape 3340, Silver, 72 mm x 45.7 m, 3.9 mil, 7010335734

16 × $33.04

3M 64324, Foil Tape 3340, Silver, 72 mm x 45.7 m, 3.9 mil, 7010335734

16 × $33.04 -

×

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62 -

×

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69 -

×

Insize 3293-061, CAN SEAM MICROMETER, 0-.5", for steel cans, 6928640328497

1 × $140.37

Insize 3293-061, CAN SEAM MICROMETER, 0-.5", for steel cans, 6928640328497

1 × $140.37 -

×

Dynabrade 94991 1/4" Female Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $44.05

Dynabrade 94991 1/4" Female Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $44.05 -

×

Standard Abrasives 707115, Spiral Band, 1 in x 1 in 50, 7010331384

100 × $0.74

Standard Abrasives 707115, Spiral Band, 1 in x 1 in 50, 7010331384

100 × $0.74 -

×

3M 12953, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 4 in, 7100007035, 100 per case

100 × $3.74

3M 12953, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 4 in, 7100007035, 100 per case

100 × $3.74 -

×

Insize 6140, DEPTH BASE ATTACHMENT, suitable for calipers with beam width (w) .630", 6928640303579

1 × $24.78

Insize 6140, DEPTH BASE ATTACHMENT, suitable for calipers with beam width (w) .630", 6928640303579

1 × $24.78 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

3M 81356, Venture Tape White Aluminum Foil Tape 1558HT, 72 mm a 45.7 m, 5.4 mil, 7010335933

32 × $70.43

3M 81356, Venture Tape White Aluminum Foil Tape 1558HT, 72 mm a 45.7 m, 5.4 mil, 7010335933

32 × $70.43 -

×

Insize 6143, DEPTH STOP FOR CALIPERS, 6928640371301

1 × $18.63

Insize 6143, DEPTH STOP FOR CALIPERS, 6928640371301

1 × $18.63 -

×

Insize 0010-A35, SOUND LEVEL METER, 35dB~130dB, 6974029777004

1 × $170.80

Insize 0010-A35, SOUND LEVEL METER, 35dB~130dB, 6974029777004

1 × $170.80 -

×

Insize 6318, CALIPER/MICROMETER GRINDING MACHINE (caliper grinding blocks are included), 6940561953862

1 × $3,744.91

Insize 6318, CALIPER/MICROMETER GRINDING MACHINE (caliper grinding blocks are included), 6940561953862

1 × $3,744.91 -

×

Insize 0131-A120, LIGHT METER, 0.01~19.99FC, 0.1~199.9FC, 1~1999FC, 10~19990FC, 0.1~199.9Lux, 1~1999Lux, 10~19990Lux, 100~199900Lux, 6974029776557

1 × $110.63

Insize 0131-A120, LIGHT METER, 0.01~19.99FC, 0.1~199.9FC, 1~1999FC, 10~19990FC, 0.1~199.9Lux, 1~1999Lux, 10~19990Lux, 100~199900Lux, 6974029776557

1 × $110.63 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $573.77

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $573.77 -

×

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

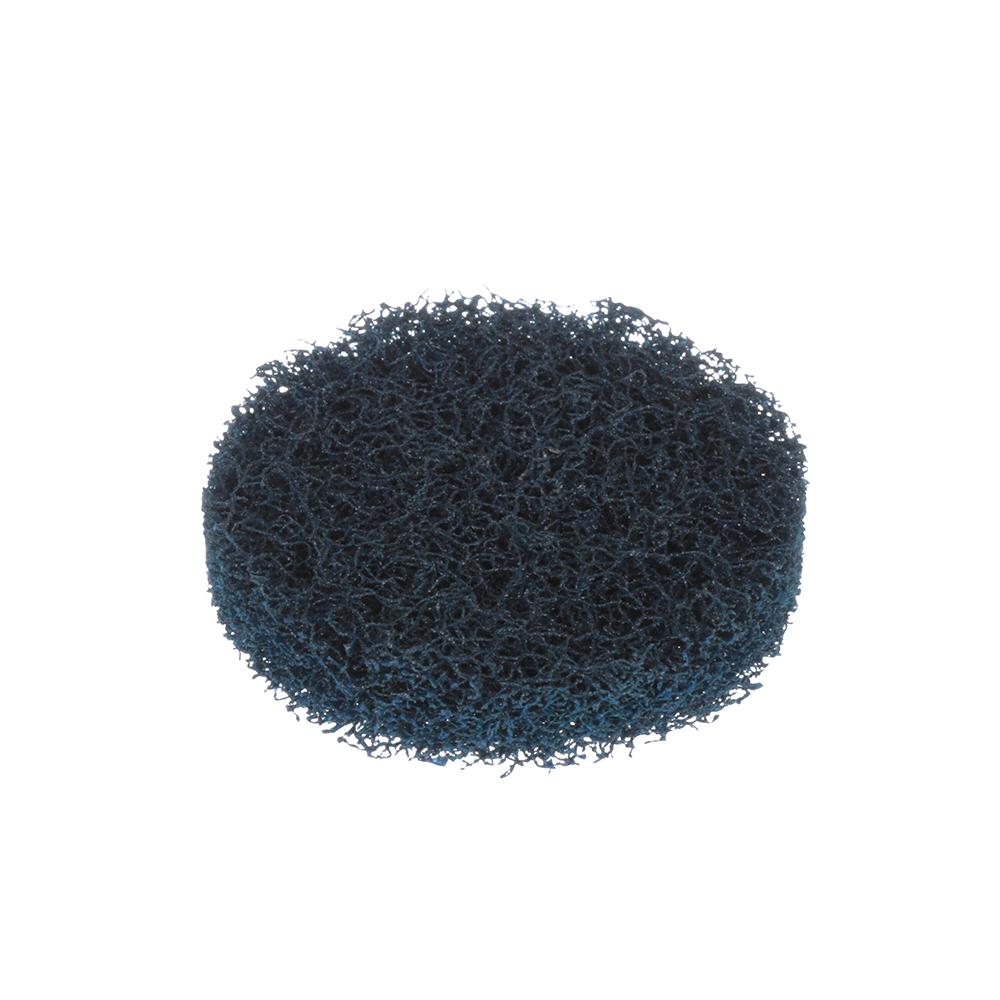

Standard Abrasives 840358, Quick Change Buff and Blend HS Disc, A/O Medium, TR, Blue, 2 in, Die Q200P, 7100074870, 50/case

$1.96

Factory Stock, 7-10 Day Leadtime

High Strength non-woven nylon material ensures that our Standard Abrasive Quick Change Buff and Blend HS Disc maintains stiffness and won’t tear or fray when faced with challenging edgework or irregular surfaces. Within the Standard Abrasive Buff and Blend product line, the HS Disc offers the best performance for cleaning and light deburring while achieving a final finish or polished piece.

Three Grades Well-Suited for Deburring and Finishing Irregular-Shaped Parts

Among the four Standard Abrasives™ Buff and Blend materials, HS material is the most stiff, durable and aggressive. Given its strength and durability, our Standard Abrasives™ Quick Change Buff and Blend HS Disc is a good match for irregular-shaped parts, such as pipe threads, the edges of molded glass containers, and non-ferrous die cast molded parts. It removes small, stubborn burrs and cuts sharp to produce a consistent finish. Non-woven construction makes the material responsive to contours and extrusions, so it is unlikely to gouge or mar the substrate while achieving an aggressive cut.

Aluminum oxide abrasive grain bonded to the nylon strands produces a uniform scratch pattern – perfect for satin or grain finishing. Use a Standard Abrasives™ Quick Change Buff and Blend HS Disc for final finishing on brass, steel, bronze, pewter, and stainless steel, as well as plated plastics.

When a very fine high luster and decorative finish is desirable on pieces such as builders hardware, choose the HS Disc in MED or VFN grade. For applications that may require a faster cut or coarser finish, choose the CRS grade disc. The coarser scratch pattern of the CRS disc also makes it ideal for satin and grain finishing applications, as well as blending and cleaning surface imperfections.

HS Coarse Features and Applications

- Produces a uniform, coarse finish similar to Surface Conditioning material

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Durable enough to finish edges and welds

- Satin and grain finishing of metal surfaces

- Blending and cleaning surface imperfections

- Blending out tool marks

- Markets include stainless steel fabricators, plumbing fixtures, metal fabricators, door hardware, food equipment Manufacturers, builder’s hardware, aluminum extruded products, and aerospace

- Green

HS Medium Features and Applications

- Rigid, durable construction accomplishes edge breaking, deburring and finishing finish edges and welds

- Satin and grain finishing of metal surfaces

- Cleaning surface contamination

- Deburring and edge breaking

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Produces a clean finish, without irregular scratches and “sparkles”

- Markets include stainless steel fabricators, plumbing fixtures, door hardware, food equipment manufacturers, aluminum extruded products, aircraft engine manufacturers, orthopedic implants

- Blue

HS Very Fine Features and Applications

- Excels at light deburring and final finishing of small, irregular shaped parts

- Light edge breaking on machined or stamped parts

- Edge radiusing

- Deburring threaded parts

- Pre-finish of precious metals prior to polishing

- Markets include aerospace, aircraft equipment, foundries, machine builders, machine shops, and mold and die shops

- Pink

When your application calls for a lighter-duty disc or if the final finish isn’t as critical, we suggest our Standard Abrasives™ Buff and Blend GP or HP Disc. For off-hand and automated finishing processes, we recommend the loftier Buff and Blend HS-F Disc.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

Quick Change Discs Provide Added Convenience and Time Savings

Standard Abrasives™ Quick Change Buff and Blend Discs are available in disc diameters up to 5 inches. Quick change discs allow tool-free swap outs, maintain secure attachment at high speeds, and save operators time when switching discs between grades or applications. Easy fastening and swapping of discs enhances tool efficiency and worker productivity. Choose the disc compatible with your TR or TS holder pad. TR discs have a nylon threaded male hub that easily threads onto TR or 3M™ Roloc™ type holder pads with a turn of the wrist, and the TS system has a metal hub that fastens to its holder pad with a simple twist.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.