-

×

Dynabrade 91430 1/2" W x 12" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 91430 1/2" W x 12" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 62612, Scotch-Weld Threadlocker TL71, Red, 10 mL Bottle, 7100039197, 10/case

10 × $13.32

3M 62612, Scotch-Weld Threadlocker TL71, Red, 10 mL Bottle, 7100039197, 10/case

10 × $13.32 -

×

Dynabrade 51630 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $604.39

Dynabrade 51630 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $604.39 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $573.77

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $573.77 -

×

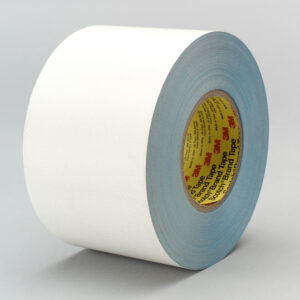

3M 40145, Thermosetable Glass Cloth Tape 3650, White, 8.3 mil, 7 in x 60 yd, 7100198501

4 × $637.89

3M 40145, Thermosetable Glass Cloth Tape 3650, White, 8.3 mil, 7 in x 60 yd, 7100198501

4 × $637.89 -

×

Dynabrade 78586 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.54

Dynabrade 78586 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.54 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 00705, Interam Stainless Steel Foil Tape T-65, 4 in x 100 ft, 7100024280

72 × $192.19

3M 00705, Interam Stainless Steel Foil Tape T-65, 4 in x 100 ft, 7100024280

72 × $192.19 -

×

Dynabrade 94992 1/4" Male Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $44.05

Dynabrade 94992 1/4" Male Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $44.05 -

×

3M 82506, Steel Mesh Faceshield Screen W96M 82506-00000, Molded 10 EA/Case, 7000127168

1 × $376.36

3M 82506, Steel Mesh Faceshield Screen W96M 82506-00000, Molded 10 EA/Case, 7000127168

1 × $376.36 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 03016, Glass Cloth Tape 361, White, 3/4 in x 60 yd, 6.4 mil, 7000047441

48 × $89.62

3M 03016, Glass Cloth Tape 361, White, 3/4 in x 60 yd, 6.4 mil, 7000047441

48 × $89.62 -

×

Dynabrade 22070 Downdraft Table Accessory Pack (Air Manifold, FRL and On/Off Air Valve)

1 × $709.91

Dynabrade 22070 Downdraft Table Accessory Pack (Air Manifold, FRL and On/Off Air Valve)

1 × $709.91 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

3M™ 37018, Supplied Air Respirator Vortex Cooling Assembly V-100/37018(AAD), 70070799013, 1 EA/Case

1 × $397.07

3M™ 37018, Supplied Air Respirator Vortex Cooling Assembly V-100/37018(AAD), 70070799013, 1 EA/Case

1 × $397.07 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.60

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.60 -

×

Standard Abrasives 708751, PSA A/O Disc, 12 in x NH, 60, 7010370081

10 × $5.83

Standard Abrasives 708751, PSA A/O Disc, 12 in x NH, 60, 7010370081

10 × $5.83 -

×

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $976.11

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $976.11 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 30,000RPM, 33432

1 × $950.00

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 30,000RPM, 33432

1 × $950.00 -

×

Dynabrade 78587 1/4" Dia. x 2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.62

Dynabrade 78587 1/4" Dia. x 2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.62

Standard Abrasives 730089, Ceramic Straight Cartridge Roll, 1/2 in x 1-1/2 in x 1/8 in 80, 7100091975

$1.04

Factory Stock, 7-10 Day Leadtime – Priced Per Roll

The unique design of our Standard Abrasives Ceramic Cartridge Roll makes it a good match for cutting ? in, over and around ? irregular surfaces and contours. Its cylindrical shape enables the abrasive to tackle hard-to-reach areas or spaces that, otherwise, might be difficult to access.

Tackling Nooks and Crannies

The multi-layered Standard Abrasives Ceramic Cartridge Roll is cylindrical in shape, which helps it roll centrifugally over irregular edges and contours. We engineer the product by rolling abrasive material into a tight cylinder resembling a small, circular barrel. This shape helps the abrasive work within nooks and crannies of the part. Cartridge rolls have an arbor hole to accommodate a mandrel tool attachment (sold separately), which attaches to a rotary tool such as a die grinder or drill. Mandrels come in different sizes to fit a variety of cartridge rolls. Together, the mandrel and roll enable the user to grind or finish hard-to-reach areas of a workpiece, such as angles and curves.

Built for Strength

Abrasive material on Standard Abrasives Ceramic Cartridge Roll is comprised of ceramic mineral, a cotton backing and cured resin. Ceramic mineral is created by heating alumina and other compounds, almost to the point of liquefaction. As the grain cools, it becomes extremely durable and tough. Ceramics cool cutting action reduces the risk for loading and part discoloration that may result from heat. These are some of the reasons it’s a good match for heat-sensitive metals like stainless steel and high nickel alloys. Given the strength and durability of the mineral, this abrasive is a good match for blending, deburring and polishing. It will stand up to the heavy pressure that often results from applications like edge breaking and flash removal. Additionally, our cartridge roll comes in a variety of sizes and grades, so you can find the one that’s best suited to your project needs.

Benefits of a Multi-Layer Design

The multi-layer, multi-wear design of Standard Abrasives Ceramic Cartridge Roll prolongs abrasive service life and helps it withstand wear and tear. As the top abrasive layer wears down over time, underlying layers are exposed. The even breakdown reveals fresh mineral, so you get a consistent cut part after part. Seemingly small, these cartridge rolls conquer big challenges when space is tight.