-

×

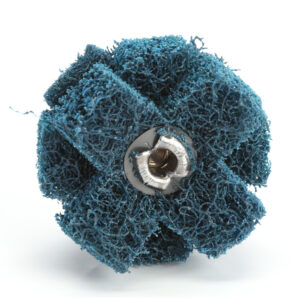

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

50 × $6.37

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

50 × $6.37 -

×

3M 55563, Performance Flatback Tape 2525, Orange, 48 mm x 55 m, 9.5 mil, 24Rolls/Case, 7000088508

24 × $28.93

3M 55563, Performance Flatback Tape 2525, Orange, 48 mm x 55 m, 9.5 mil, 24Rolls/Case, 7000088508

24 × $28.93 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

Standard Abrasives 875710, HS Mini-Brush, 4-1/2 in x 2 in x 5/8-11 FB024 35-74 A MED Medium Density, 7100082653

2 × $71.59

Standard Abrasives 875710, HS Mini-Brush, 4-1/2 in x 2 in x 5/8-11 FB024 35-74 A MED Medium Density, 7100082653

2 × $71.59 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07 -

×

3M 90575, Regalite Hookit Heavy Duty Discs 5RQC60-8, 5 in x 8 hole, 60 grit, 7010331757

200 × $0.90

3M 90575, Regalite Hookit Heavy Duty Discs 5RQC60-8, 5 in x 8 hole, 60 grit, 7010331757

200 × $0.90 -

×

Dynabrade 92119 1/4" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 92119 1/4" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $400.59 -

×

Dynabrade 91166 1/2" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

100 × $1.81

Dynabrade 91166 1/2" W x 13" L 80 Grit A/O DynaCut Belt, 50/pack

100 × $1.81 -

×

3M 26000, PPS Series 2.0 Spray Cup System Kit, Standard (22 fl oz, 650mL), 200u Micron Filter, 7100135954

1 × $126.42

3M 26000, PPS Series 2.0 Spray Cup System Kit, Standard (22 fl oz, 650mL), 200u Micron Filter, 7100135954

1 × $126.42 -

×

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

100 × $1.07

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

100 × $1.07 -

×

Dynabrade 91164 3/8" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.60

Dynabrade 91164 3/8" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.60 -

×

3M 92768, Heavy Duty Stripping Tool 10110NA-PT, 3 Coarse, One, Open Stock, 3.375 in. x 5 in. Handle and Pad, 7010292604

6 × $4.17

3M 92768, Heavy Duty Stripping Tool 10110NA-PT, 3 Coarse, One, Open Stock, 3.375 in. x 5 in. Handle and Pad, 7010292604

6 × $4.17 -

×

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Insize 6140, DEPTH BASE ATTACHMENT, suitable for calipers with beam width (w) .630", 6928640303579

1 × $24.78

Insize 6140, DEPTH BASE ATTACHMENT, suitable for calipers with beam width (w) .630", 6928640303579

1 × $24.78 -

×

3M 13373, Scotch-Brite Star, 4 in A CRS LS, 7000120968

50 × $10.00

3M 13373, Scotch-Brite Star, 4 in A CRS LS, 7000120968

50 × $10.00 -

×

3M 19771, Utility Cloth Sheet 314D, 9 in x 11 in P100 J-weight, 7000021272

250 × $1.43

3M 19771, Utility Cloth Sheet 314D, 9 in x 11 in P100 J-weight, 7000021272

250 × $1.43 -

×

Dynabrade 79202 1/2" W x 12" L Belt Assortment Pak

1 × $27.24

Dynabrade 79202 1/2" W x 12" L Belt Assortment Pak

1 × $27.24 -

×

Dynabrade 92114 1/2" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 92114 1/2" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Standard Abrasives 726072, A/O C2 Straight Precision Cartridge Roll, 5/8 in x 2-1/2 in x 1/4 in 120, 7100098781

$4.94

Factory Stock, 7-10 Day Leadtime – Priced Per Roll

Our Standard Abrasives Aluminum Oxide Precision Cartridge Roll Model C is ideal for high-speed grinding and deburring on irregular contours and other hard-to-reach areas on all ferrous metals. The drive stem is securely affixed within the roll and resin-bonded to the inner layers. This solid construction supports use with larger tools and higher pressure, and enables a smoother application.