-

×

Standard Abrasives 78529, Ceramic Pro Type 29 Flap Disc, 645141, 7 in x 5/8-11 80 Y-weight, 7010331466

10 × $17.89

Standard Abrasives 78529, Ceramic Pro Type 29 Flap Disc, 645141, 7 in x 5/8-11 80 Y-weight, 7010331466

10 × $17.89 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

3M 97957, Hi-Strength Spray Adhesive 90 CA, Low VOC <25%, Clear, 24 fl oz Can (Net Wt 19.0 oz), 7000121418, 12/Case

12 × $21.93

3M 97957, Hi-Strength Spray Adhesive 90 CA, Low VOC <25%, Clear, 24 fl oz Can (Net Wt 19.0 oz), 7000121418, 12/Case

12 × $21.93 -

×

3M 99437, Drywall Sanding Screens, 4-3/16 in x 11-1/4 in, 150 grit, 7010370929, 10 sheets per pack

20 × $14.12

3M 99437, Drywall Sanding Screens, 4-3/16 in x 11-1/4 in, 150 grit, 7010370929, 10 sheets per pack

20 × $14.12 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

Dynabrade 78602 1/2" Dia. x 1" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.62

Dynabrade 78602 1/2" Dia. x 1" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.62 -

×

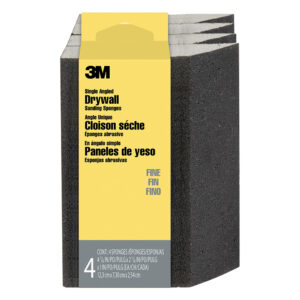

3M 91004, Drywall Sanding Sponge CP-042-4PK, Single Angle, 4-7/8 in x 2-7/8 in x 1 in, Fine, 7100111452, 4/pack

6 × $5.94

3M 91004, Drywall Sanding Sponge CP-042-4PK, Single Angle, 4-7/8 in x 2-7/8 in x 1 in, Fine, 7100111452, 4/pack

6 × $5.94 -

×

3M 99436, Drywall Sanding Screens, 4-3/16 in x 11-1/4 in, 220 grit, 7000047623, 10 sheets per pack

10 × $14.16

3M 99436, Drywall Sanding Screens, 4-3/16 in x 11-1/4 in, 220 grit, 7000047623, 10 sheets per pack

10 × $14.16 -

×

Standard Abrasives 32920, PSA A/O Disc, 708027, 6 in x NH, 120, 7100083004

50 × $1.27

Standard Abrasives 32920, PSA A/O Disc, 708027, 6 in x NH, 120, 7100083004

50 × $1.27 -

×

3M 93284, Drywall Sanding Sponge 9095DC-NA-4PK, Dual Grit Block, 2-7/8 in x 4-7/8 in x 1 in, Fine/Medium, 7100140504, 4/pack

6 × $5.21

3M 93284, Drywall Sanding Sponge 9095DC-NA-4PK, Dual Grit Block, 2-7/8 in x 4-7/8 in x 1 in, Fine/Medium, 7100140504, 4/pack

6 × $5.21 -

×

3M 08367, Urethane Seam Sealer, Black, 310 mL Cartridge, 7000119968, 12 per case

12 × $26.40

3M 08367, Urethane Seam Sealer, Black, 310 mL Cartridge, 7000119968, 12 per case

12 × $26.40 -

×

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Dynabrade 91164 3/8" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.71

Dynabrade 91164 3/8" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.71

Standard Abrasives 726070, A/O C2 Straight Precision Cartridge Roll, 5/8 in x 2-1/2 in x 1/4 in 60, 7100098797

$4.77

Factory Stock, 7-10 Day Leadtime – Priced Per Roll

Our Standard Abrasives Aluminum Oxide Precision Cartridge Roll Model C is ideal for high-speed grinding and deburring on irregular contours and other hard-to-reach areas on all ferrous metals. The drive stem is securely affixed within the roll and resin-bonded to the inner layers. This solid construction supports use with larger tools and higher pressure, and enables a smoother application.