-

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

Standard Abrasives 592304, Quick Change Aluminum Oxide 2 Ply Disc, 50, TR, Brown, 1-1/2 in, Die Q150S, 7010310670, 50/case

100 × $0.50

Standard Abrasives 592304, Quick Change Aluminum Oxide 2 Ply Disc, 50, TR, Brown, 1-1/2 in, Die Q150S, 7010310670, 50/case

100 × $0.50 -

×

3M 27008, 642WY, 3" X 30", 50000 Mesh, Diamond Cloth Belts, 7010533172

1 × $147.65

3M 27008, 642WY, 3" X 30", 50000 Mesh, Diamond Cloth Belts, 7010533172

1 × $147.65 -

×

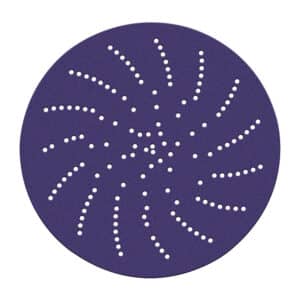

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

3M 45718, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, D/F 5HL, Die 500FH, 7100113075

200 × $1.78

3M 45718, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, D/F 5HL, Die 500FH, 7100113075

200 × $1.78 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Standard Abrasives 726070, A/O C2 Straight Precision Cartridge Roll, 5/8 in x 2-1/2 in x 1/4 in 60, 7100098797

$4.77

Factory Stock, 7-10 Day Leadtime – Priced Per Roll

Our Standard Abrasives Aluminum Oxide Precision Cartridge Roll Model C is ideal for high-speed grinding and deburring on irregular contours and other hard-to-reach areas on all ferrous metals. The drive stem is securely affixed within the roll and resin-bonded to the inner layers. This solid construction supports use with larger tools and higher pressure, and enables a smoother application.