-

×

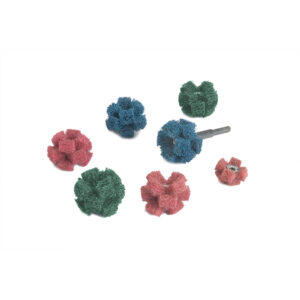

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56 -

×

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

50 × $3.75

Standard Abrasives 725002, Buff and Blend Cross Buff GP, A/O VFN, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7010368694

50 × $3.75 -

×

3M 75950, 663FC, 2" X 120", 20u, Diamond Trizact Belt 7100210740

1 × $1,278.01

3M 75950, 663FC, 2" X 120", 20u, Diamond Trizact Belt 7100210740

1 × $1,278.01 -

×

3M 62714, Scotch-Weld Stainless Steel High Temperature Pipe Sealant PS67, White, 50 mL Tube, 7100039216, 10/case

30 × $22.24

3M 62714, Scotch-Weld Stainless Steel High Temperature Pipe Sealant PS67, White, 50 mL Tube, 7100039216, 10/case

30 × $22.24 -

×

Insize 4808, WIRE GAGE, 0-36(.3249~.0050"), 6928640330155

1 × $33.19

Insize 4808, WIRE GAGE, 0-36(.3249~.0050"), 6928640330155

1 × $33.19 -

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.76

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

50 × $1.76 -

×

3M 55722, Stikit Film Disc 375L, 6 x NH P1000 w/Skipslit Liner, 7100075240, 250 per case

250 × $0.76

3M 55722, Stikit Film Disc 375L, 6 x NH P1000 w/Skipslit Liner, 7100075240, 250 per case

250 × $0.76 -

×

3M 19765, Utility Cloth Sheet 314D, 9 in x 11 in P280 J-weight, 7000000353

250 × $1.37

3M 19765, Utility Cloth Sheet 314D, 9 in x 11 in P280 J-weight, 7000000353

250 × $1.37 -

×

3M 19773, Utility Cloth Sheet 314D, 9 in x 11 in P60 X-weight, 7000000360

50 × $1.75

3M 19773, Utility Cloth Sheet 314D, 9 in x 11 in P60 X-weight, 7000000360

50 × $1.75 -

×

3M 26104, PPS Series 2.0 Adapter, Type S20, 1/8 Male, 27 Thread NPSM, 7100135929

2 × $25.96

3M 26104, PPS Series 2.0 Adapter, Type S20, 1/8 Male, 27 Thread NPSM, 7100135929

2 × $25.96 -

×

Dynabrade 78601 3/8" Dia. x 2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.72

Dynabrade 78601 3/8" Dia. x 2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.72 -

×

3M 94734, Cubitron ll Cloth Belt 947A, 80+ X-weight, 3-1/2 in x 15-1/2 in, Fabri-lok, Single-flex, 7100093313, 50 per case

50 × $7.20

3M 94734, Cubitron ll Cloth Belt 947A, 80+ X-weight, 3-1/2 in x 15-1/2 in, Fabri-lok, Single-flex, 7100093313, 50 per case

50 × $7.20 -

×

Insize 0020-A199, VIBRATION PEN (THREE PARAMETERS), 6974029777059

1 × $1,044.21

Insize 0020-A199, VIBRATION PEN (THREE PARAMETERS), 6974029777059

1 × $1,044.21 -

×

Dynabrade 78594 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $50.00

Dynabrade 78594 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $50.00 -

×

Dynabrade 78598 3/8" Dia. x 2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.72

Dynabrade 78598 3/8" Dia. x 2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.72 -

×

Dynabrade 78597 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.61

Dynabrade 78597 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.61 -

×

Dynabrade 78602 1/2" Dia. x 1" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.58

Dynabrade 78602 1/2" Dia. x 1" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $0.58 -

×

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91426 1/4" W x 12" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Insize 7230, SCRIBER, 6928640320064

1 × $6.77

Insize 7230, SCRIBER, 6928640320064

1 × $6.77 -

×

3M 45017, Diamond Grade DG3 Reflective Digital Sheeting 4091UDS,Yellow, 30 in x 50 yd, 1 Roll/Case, 7100282697

1 × $1,962.81

3M 45017, Diamond Grade DG3 Reflective Digital Sheeting 4091UDS,Yellow, 30 in x 50 yd, 1 Roll/Case, 7100282697

1 × $1,962.81 -

×

Insize 4809, U.S. STAND SHEET METAL GAGE, 0-36(.3125~.0070"), 6928640330162

1 × $35.18

Insize 4809, U.S. STAND SHEET METAL GAGE, 0-36(.3125~.0070"), 6928640330162

1 × $35.18 -

×

Insize 6313-1D4, SETTING RING, 1.4" dia, 6928640357749

1 × $100.51

Insize 6313-1D4, SETTING RING, 1.4" dia, 6928640357749

1 × $100.51 -

×

3M 81284, Scotch-Weld High Strength Retaining Compound RT38, Green, 250 mL Bottle, 7010367436, 2/case

2 × $142.89

3M 81284, Scotch-Weld High Strength Retaining Compound RT38, Green, 250 mL Bottle, 7010367436, 2/case

2 × $142.89 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

Insize 1121-150A, DIGITAL INSIDE POINT CALIPER, .9-6"/24-150mm, 6928640302251

1 × $252.14

Insize 1121-150A, DIGITAL INSIDE POINT CALIPER, .9-6"/24-150mm, 6928640302251

1 × $252.14 -

×

3M 97957, Hi-Strength Spray Adhesive 90 CA, Low VOC <25%, Clear, 24 fl oz Can (Net Wt 19.0 oz), 7000121418, 12/Case

24 × $21.93

3M 97957, Hi-Strength Spray Adhesive 90 CA, Low VOC <25%, Clear, 24 fl oz Can (Net Wt 19.0 oz), 7000121418, 12/Case

24 × $21.93 -

×

Standard Abrasives 840039, Quick Change Surface Conditioning GP Disc, A/O Very Fine, TSM, BLU, 3/4 in, QS75KM, 7000121840, 50/case

50 × $0.84

Standard Abrasives 840039, Quick Change Surface Conditioning GP Disc, A/O Very Fine, TSM, BLU, 3/4 in, QS75KM, 7000121840, 50/case

50 × $0.84 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

1 × $25.96

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

1 × $25.96 -

×

3M 82220, Hot Melt Adhesive 3747 AE, Tan, 0.45 in x 12 in, 7100020323, 11 LBS/Case

11 × $31.50

3M 82220, Hot Melt Adhesive 3747 AE, Tan, 0.45 in x 12 in, 7100020323, 11 LBS/Case

11 × $31.50 -

×

Dynabrade 78593 3/8" Dia. x 1" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.51

Dynabrade 78593 3/8" Dia. x 1" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.51 -

×

Insize 0131-A120, LIGHT METER, 0.01~19.99FC, 0.1~199.9FC, 1~1999FC, 10~19990FC, 0.1~199.9Lux, 1~1999Lux, 10~19990Lux, 100~199900Lux, 6974029776557

1 × $110.63

Insize 0131-A120, LIGHT METER, 0.01~19.99FC, 0.1~199.9FC, 1~1999FC, 10~19990FC, 0.1~199.9Lux, 1~1999Lux, 10~19990Lux, 100~199900Lux, 6974029776557

1 × $110.63 -

×

3M 16236, PPS Spray Gun Holder, Single Gun, 7100152679

5 × $99.23

3M 16236, PPS Spray Gun Holder, Single Gun, 7100152679

5 × $99.23 -

×

Dynabrade 78582 1/4" Dia. x 1" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.45

Dynabrade 78582 1/4" Dia. x 1" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.45 -

×

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22

3M 33446, Cubitron II File Belt, 80+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033186, 10 belts per carton, 5 cartons per case

5 × $34.22 -

×

Dynabrade 58058 5/8"-11 Female 5/8"-11 Male, 2" Length

1 × $147.51

Dynabrade 58058 5/8"-11 Female 5/8"-11 Male, 2" Length

1 × $147.51 -

×

Insize 7332, SPINDLE LIFT KNOB, 6928640312649

1 × $4.60

Insize 7332, SPINDLE LIFT KNOB, 6928640312649

1 × $4.60 -

×

3M 45033, High Intensity Prismatic Reflective Digital Sheeting 3930UDS, White, 24 in x 50 yd, 1 Roll/Case, 7100282394

1 × $641.74

3M 45033, High Intensity Prismatic Reflective Digital Sheeting 3930UDS, White, 24 in x 50 yd, 1 Roll/Case, 7100282394

1 × $641.74 -

×

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $0.95

Dynabrade 92210 1/8" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $0.95

Standard Abrasives 700939, A/O Full Taper Cartridge Roll, 1/2 in x 1-1/2 in x 1/8 in 120, 7100092989

$0.78

Factory Stock, 7-10 Day Leadtime – Priced Per Roll

Our Standard Abrasives Aluminum Oxide Cartridge Roll is ideal for fast cutting on irregular contours and other hard-to-reach areas on all ferrous metals.

Recommended Applications

The multi-layered Standard Abrasives Aluminum Oxide Cartridge Roll exposes new abrasive cutting points throughout the life of the roll. Combining an aggressive cut with durability makes it great for polishing, edge breaking and removal of machine tool marks or flash. Its small size and shape enable it to blend, deburr and polish inside holes and diameters or on irregular surfaces and contours. The cartridge roll has an arbor hole to accommodate a mandrel tool attachment (sold separately). This mandrel attaches to a rotary tool such as a die grinder or drill and comes in different sizes to fit a variety of cartridge roll sizes. Together, the mandrel and cartridge roll enable the user to grind or finish hard-to-reach areas of a workpiece, such as angles and curves.

The Aluminum Oxide Cartridge Rolls come in a variety of sizes and grades, so it can be tailored to meet your project needs. Grades range from 36 to 400, producing a spectrum of finishes, from coarse to fine. It is made with aluminum oxide mineral, which cuts sharp and is friable – fragmenting under heat and pressure to reveal sharp cutting edges as it abrades the surface. The straight roll design is cylindrical, which helps it roll over irregular contours.

Benefits of a Multi-Layer Design

The multi-layer, multi-wear design of Standard Abrasives Aluminum Oxide Cartridge Roll keeps it cutting sharp and helps it withstand repeated wear. As top layers wear down over time, underlying layers expose fresh mineral, so you get a consistent cut, part after part. Wrapping multiple layers of the abrasive material around into a roll contributes to its sturdiness and durability. A resin bond securely anchors mineral to the cloth backing – also enhancing the abrasive’s toughness and strength. The closed-coat construction means mineral grains cover 100 percent of the cloth backing, so you get a smoother, more consistent finish is achieved. Seemingly small, these cartridge rolls conquer big challenges when space gets tight.