-

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

30 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

30 × $9.52 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 14537 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 37 in x 60 in, 7100117782

1 × $532.80

3M 14537 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 37 in x 60 in, 7100117782

1 × $532.80 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

Dynabrade 53245 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 8,500 RPM, 5/8"-11 Spindle

1 × $1,591.00

Dynabrade 53245 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 8,500 RPM, 5/8"-11 Spindle

1 × $1,591.00 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 91970, Hydrogen Fluoride Cartridge/Filter 7093CB, P100, with Nuisance Level Organic Vapor and Acid Gas Relief, 7000126938, 144 EA/Case

1 × $1,158.78

3M 91970, Hydrogen Fluoride Cartridge/Filter 7093CB, P100, with Nuisance Level Organic Vapor and Acid Gas Relief, 7000126938, 144 EA/Case

1 × $1,158.78 -

×

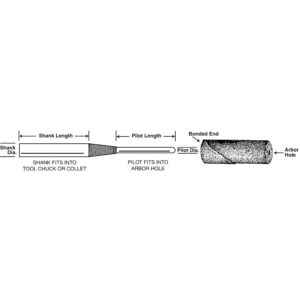

Standard Abrasives 713286, Mandrel, 1/4 in x 1/4 in x 2 in DM-7, 7000121806

5 × $7.95

Standard Abrasives 713286, Mandrel, 1/4 in x 1/4 in x 2 in DM-7, 7000121806

5 × $7.95

3M 82531, Finesse-it Natural Buffing Pad, 82531, 7 in, 10 ea/Case, 7000028364

$28.00

Factory Stock, 7-10 Day Leadtime

3M Finesse-it Natural Buffing Pad is made with select lamb?s wool hide, trimmed to 20 mm length to offer a more aggressive cut than longer-fiber pads. The natural hide holds each fiber individually, which minimizes lint discharge. The dense pile surface holds the polish for even, consistent material distribution while minimizing splatter and jumping.

Our Finesse-it Natural Buffing Pad is ideal for buffing automotive OEM, marine, and aerospace coatings. When used in conjunction with our Finesse-it polishes, the pad quickly removes finishing abrasive sand scratches, oxidation, and other paint surface defects. Resulting finish may require a follow up polishing step with a finer pad to completely remove swirl marks. This pad is manufactured with the 3M Hookit attachment system for quick pad mounting and removal, and to hold the pad securely in place during use. Our Hookit buffing pads conveniently and firmly attach to a hook-and-loop backup disc pad (sold separately) on rotary or random orbital tools, can be removed cleanly and easily, and can be re-used again and again for the life of the pad. Finish results are dependent on specific polish used, coating type, and the tool used.

Wool buffing pads are generally more aggressive and easier to control than foam pads. They have a greater available cutting surface area due to the presence of thousands of fibers. These fibers provide faster cutting action than foam pads, Wool fibers hold the polish to provide even distribution of material and require less pressure from the operator. The nap helps wool pads glide and conform to contours, making them easier to control than foam pads. Because of their cutting ability, wool pads are effective for removing sanding scratches and perform best on rotary type buffing tools. Depending on the polish type, individual technique, composition of the coating, and the tool used, finishing with a wool pad may require a follow-up step with a foam pad and polish to remove micro-marring or swirl marks.

Our Finesse-it products are a line of specially engineered abrasives, compounds, polishes, and buffing pads to be used on OEM and baked refinish paints to remove defects, sand scratches, or swirl marks on a variety of painted surfaces. 3M Finesse-it products are an integral part of a 3M recommended buffing system for repairing surface defects to clear coats, lacquered wood, solid surfaces, gelcoat, powder coat, industrial paint, acrylic, and glass.