-

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

100 × $3.54

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

100 × $3.54 -

×

Dynabrade 79123 1/2" W x 18" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.45

Dynabrade 79123 1/2" W x 18" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.45 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 95848 Dynabrade Gear Oil

2 × $12.37

Dynabrade 95848 Dynabrade Gear Oil

2 × $12.37 -

×

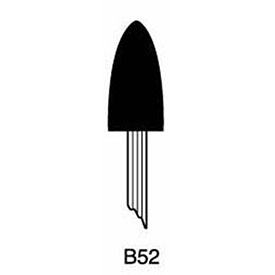

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Dynabrade 79967 5" Dia. x 60 Grit A/O Non-Vacuum PSA DynaCut Disc, 100/Box

1 × $51.23

Dynabrade 79967 5" Dia. x 60 Grit A/O Non-Vacuum PSA DynaCut Disc, 100/Box

1 × $51.23 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,583.72 -

×

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21 -

×

Dynabrade 61204 RaptorVac Pneumatic DrumVac Kit, Single Operator, General Purpose

1 × $1,930.40

Dynabrade 61204 RaptorVac Pneumatic DrumVac Kit, Single Operator, General Purpose

1 × $1,930.40 -

×

Dynabrade 80538 Mini-Raptor 2 Vac M-Class Filter

1 × $43.50

Dynabrade 80538 Mini-Raptor 2 Vac M-Class Filter

1 × $43.50 -

×

Dynabrade 78316 2" Dia. x 1" W x 1/4" Shank, Medium, NWN DynaBrite Wheel, 10/pack

10 × $12.50

Dynabrade 78316 2" Dia. x 1" W x 1/4" Shank, Medium, NWN DynaBrite Wheel, 10/pack

10 × $12.50 -

×

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Dynabrade 92150 1/2" W x 18" L 80 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

50 × $4.35

Dynabrade 92150 1/2" W x 18" L 80 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

50 × $4.35 -

×

Dynabrade 79109 1/2" W x 12" L 80 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.89

Dynabrade 79109 1/2" W x 12" L 80 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.89 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 86775, Cubitron ll Cloth Belt 947A, 40+ X-weight, 3/4 in x 18 in, Fabri-lok, Single-flex, 7100033084, 200 per case

$2.93

Factory Stock, 7-10 Day Leadtime

Our 3M Cubitron II Abrasive Belt 947A built with 3M Precision-Shaped Grain cuts metal dramatically faster and cooler, and stays sharp longer than conventional ceramic belts. Its X-weight poly-cotton backing is flexible. This belt is optimized for low and medium pressure applications on stainless steel, mild steels, and aluminum.

Fast and Flexible

A closed coat and a grinding aid make our 3M Cubitron II Abrasive Belt 947A an outstanding option for low to medium pressure applications on heat sensitive metals. The nature of the abrasive structure diverts heat to the swarf, keeping both belt and workpiece cooler. It is now available in grades 40+ (make to order), 60+, 80+ and now 120+ adding an improved solution for finer finishing applications.

Cutting Edge Performance for Low and Medium Pressure Sanding

A semi flexible Cubitron II belt the 3M 947A sports an X-weight poly-cotton backing. Among backing weights, an X-weight cloth is flexible and provides tensile strength as well.

A great number of small belt sizes which are nimble and maneuverable so operators can get in, over and around intricate parts. These belts are good options for low-and-medium-pressure offhand operations for use on the following equipment:

- Backstands

- File Belt Sanders

- Inline Sanders

- Stroke Sanders

How 3M Precision-Shaped Grain Works

3M Precision-Shaped Grain is designed to continuously fracture to form sharp points and edges that easily ?slice? through metal. It cuts faster, lasts longer and stays cooler.

Conventional ceramic abrasive grain tends to ?plow? through the metal, causing heat to build up in the workpiece and the abrasive ? resulting in a slower cut, shorter belt life and undesirable effects, such as burnishing.

3M Science. The Beginning of Cubitron II.

In 2009, 3M scientists had long believed abrasives would work better if each grain of the ceramic abrasive material was exactly the same size and shape. It would act more like a knife shaving off material and less like a plow bouncing along the surface, creating heat damage. The breakthrough came when they realized they could use microreplication technology 3M was already using to create reflective material for signs, and other purposes.

Within a short time, they had created 3M’s Precision Shaped Grain ? identical triangular-shaped abrasive grains electrostatically oriented and distributed uniformly on an abrasive backing. The end result is faster, cooler cutting action, improved productivity, less operator fatigue and longer belt life.