-

×

Dynabrade 52673 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 4,500 RPM, 1/4" Collet

1 × $1,017.23

Dynabrade 52673 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 4,500 RPM, 1/4" Collet

1 × $1,017.23 -

×

Dynabrade 53696 Flange

1 × $43.80

Dynabrade 53696 Flange

1 × $43.80 -

×

Dynabrade 55650 4 hp Rear Gasket

1 × $7.20

Dynabrade 55650 4 hp Rear Gasket

1 × $7.20 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65 -

×

Dynabrade 40742 Field Coil Assembly

1 × $79.30

Dynabrade 40742 Field Coil Assembly

1 × $79.30 -

×

Dynabrade 47800 .4 hp Right Angle Die Grinder, Front Exhaust, 12,000 RPM, 1/4" Collet

1 × $708.47

Dynabrade 47800 .4 hp Right Angle Die Grinder, Front Exhaust, 12,000 RPM, 1/4" Collet

1 × $708.47 -

×

Dynabrade 96245 Repair Collar-.992" Bore

1 × $35.86

Dynabrade 96245 Repair Collar-.992" Bore

1 × $35.86 -

×

Dynabrade 57045 Balancer Assy with V-Seal

1 × $45.40

Dynabrade 57045 Balancer Assy with V-Seal

1 × $45.40 -

×

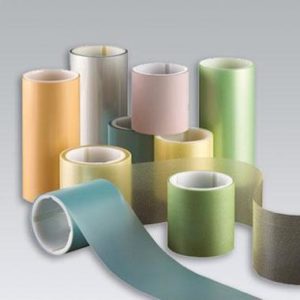

Dynabrade 92758 3" W x 150' L 9 Micron A/O Lapping Film DynaCut Roll

1 × $178.44

Dynabrade 92758 3" W x 150' L 9 Micron A/O Lapping Film DynaCut Roll

1 × $178.44 -

×

Dynabrade 92100 3" W x 10-11/16" L 40 Grit A/Z DynaCut Belt, 10/pack

10 × $4.25

Dynabrade 92100 3" W x 10-11/16" L 40 Grit A/Z DynaCut Belt, 10/pack

10 × $4.25 -

×

Dynabrade 96173 Motor Tune-Up Kit

1 × $171.52

Dynabrade 96173 Motor Tune-Up Kit

1 × $171.52 -

×

Dynabrade 50983 Wet Spindle

1 × $186.11

Dynabrade 50983 Wet Spindle

1 × $186.11 -

×

Dynabrade 07129 Gasket

1 × $5.96

Dynabrade 07129 Gasket

1 × $5.96 -

×

Dynabrade 46001 .4 hp Right Angle Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

2 × $731.21

Dynabrade 46001 .4 hp Right Angle Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

2 × $731.21 -

×

Dynabrade 21692 NDDP1060, Pad Plate Grommet

1 × $6.76

Dynabrade 21692 NDDP1060, Pad Plate Grommet

1 × $6.76 -

×

Dynabrade 78705 1-1/2" x 8-32 Female Center Thread, Medium, Dynabrite Surface Conditioning Eyelet Star, 50/pack

50 × $148.50

Dynabrade 78705 1-1/2" x 8-32 Female Center Thread, Medium, Dynabrite Surface Conditioning Eyelet Star, 50/pack

50 × $148.50 -

×

Dynabrade 64116 Filter

1 × $100.49

Dynabrade 64116 Filter

1 × $100.49 -

×

Dynabrade 56844BK 3-1/2" Dia. Central Vacuum Dynorbital Supreme Random Orbital Sander

1 × $2,314.26

Dynabrade 56844BK 3-1/2" Dia. Central Vacuum Dynorbital Supreme Random Orbital Sander

1 × $2,314.26 -

×

Dynabrade 53334 Spacer, 28 mm

1 × $8.99

Dynabrade 53334 Spacer, 28 mm

1 × $8.99 -

×

Dynabrade Nitro Series MNF1K Mini-NitroFile Abrasive Belt Tool Versatility Kit

1 × $569.50

Dynabrade Nitro Series MNF1K Mini-NitroFile Abrasive Belt Tool Versatility Kit

1 × $569.50 -

×

Dynabrade 93546 1-1/2" Dia. x 8-32 Female Center Thread, 320 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $10.92

Dynabrade 93546 1-1/2" Dia. x 8-32 Female Center Thread, 320 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $10.92 -

×

Dynabrade Nitro Series DS32 .3hp, 16,000 RPM, 2" Right Angle Disc Sander

1 × $145.85

Dynabrade Nitro Series DS32 .3hp, 16,000 RPM, 2" Right Angle Disc Sander

1 × $145.85 -

×

Dynabrade 78706 2" x 1/4"-20 Female Center Thread, Coarse, Dynabrite Surface Conditioning Eyelet Star, 50/pack

100 × $4.05

Dynabrade 78706 2" x 1/4"-20 Female Center Thread, Coarse, Dynabrite Surface Conditioning Eyelet Star, 50/pack

100 × $4.05 -

×

Dynabrade 01580 Felt Silencer

1 × $3.86

Dynabrade 01580 Felt Silencer

1 × $3.86 -

×

Dynabrade 53456 Housing for Model 53455, 950 RPM

1 × $102.11

Dynabrade 53456 Housing for Model 53455, 950 RPM

1 × $102.11 -

×

Dynabrade 53734 Housing for Model 52578; 20,000 RPM

1 × $168.29

Dynabrade 53734 Housing for Model 52578; 20,000 RPM

1 × $168.29 -

×

Dynabrade 93658 3" Dia. x 3/8" CH 40/50 Grit Gulleted/Slotted Diamond Cut-Off Wheel

1 × $117.02

Dynabrade 93658 3" Dia. x 3/8" CH 40/50 Grit Gulleted/Slotted Diamond Cut-Off Wheel

1 × $117.02 -

×

Dynabrade 93345 Carbide Burr, 1/8" Dia., SG-44 D/C Burr, Tree-Radiused End, 1/2" Flute L, 1/8" Shank

1 × $15.84

Dynabrade 93345 Carbide Burr, 1/8" Dia., SG-44 D/C Burr, Tree-Radiused End, 1/2" Flute L, 1/8" Shank

1 × $15.84 -

×

Dynabrade 78393 8" Dia. x 2" W x 3" Center Hole, 2S Coarse, S/C DynaBrite Multi-Finish Convolute Wheel, 2/box

2 × $127.79

Dynabrade 78393 8" Dia. x 2" W x 3" Center Hole, 2S Coarse, S/C DynaBrite Multi-Finish Convolute Wheel, 2/box

2 × $127.79 -

×

Dynabrade 89212 Plug

1 × $1.93

Dynabrade 89212 Plug

1 × $1.93 -

×

Dynabrade 25208 Housing Ass'y for Model 52639

1 × $254.05

Dynabrade 25208 Housing Ass'y for Model 52639

1 × $254.05 -

×

Dynabrade 53797 Housing for Model 13523

1 × $168.29

Dynabrade 53797 Housing for Model 13523

1 × $168.29 -

×

Dynabrade 02227 Housing for Model 51232

1 × $102.11

Dynabrade 02227 Housing for Model 51232

1 × $102.11 -

×

Dynabrade 25234 Vane Set (4pk)

1 × $26.39

Dynabrade 25234 Vane Set (4pk)

1 × $26.39 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 51302 .5 hp Straight-Line Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $431.21

Dynabrade 51302 .5 hp Straight-Line Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $431.21 -

×

Dynabrade 97034 Screw

1 × $1.93

Dynabrade 97034 Screw

1 × $1.93 -

×

Dynabrade 33666 ND6390, Paper Clamp Lever Rivet

1 × $1.50

Dynabrade 33666 ND6390, Paper Clamp Lever Rivet

1 × $1.50 -

×

Dynabrade 15336 Rubber Drive Wheel

1 × $71.38

Dynabrade 15336 Rubber Drive Wheel

1 × $71.38 -

×

Dynabrade 15300 Dynafile III Abrasive Belt Tool

1 × $896.53

Dynabrade 15300 Dynafile III Abrasive Belt Tool

1 × $896.53 -

×

Dynabrade 96087 Washer

1 × $1.93

Dynabrade 96087 Washer

1 × $1.93 -

×

Dynabrade 02686 Bearing, 3/4" OD x 1/4" ID x 9/32" W

1 × $18.25

Dynabrade 02686 Bearing, 3/4" OD x 1/4" ID x 9/32" W

1 × $18.25 -

×

Dynabrade 50750 Spacer

1 × $34.88

Dynabrade 50750 Spacer

1 × $34.88 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 7100231078, Cloth Belt 340D, 80 X-weight, 4 in x 24 in, Film-lok, Single-flex, 50 per case

$4.77

Factory Stock, 7-10 Day Leadtime

3M Cloth Belt 340D is our open coat premium grade aluminum oxide cloth belt that provides durability for aggressive stock removal, resists loading, and is suitable for a variety of applications on wood and metal. We recommended this belt for wide belt sanding, edge sanding, or portable belt sanding.

Fast-cutting aluminum oxide abrasive grains are resin-bonded to a durable cotton cloth backing to provide continuous cut and long-life. Our open coat and load-resistant coating make this belt particularly favorable for sanding soft woods. Additionally, the washable backing is suitable for high production environments where the belt may need washing at intervals to remove soft wood resin or pitch buildup.

Aluminum oxide mineral is a popular choice among industrial professionals because of its cut-rate, durability, and long life. It can be used on a wide variety of materials in both woodworking and metalworking, including ferrous alloys, and is the most commonly used industrial abrasive. The abrasive particles are adhered to the cloth backing with resin, creating a strong bond that withstands high heat and pressure.

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. At 3M we offer a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Belts come with various splices that join the belt ends. A film media splice achieves a secure bond with a joining film that minimizes chatter marks, ensures a smooth running belt, and produces consistent finishing results. A sine wave splice is constructed of interlocking fingers that enable the splice to travel smoothly over contact wheels, reduce hinging, and provide added strength to the joint area. Sine wave splices are typically used for coarser grades and wide belts as well as on belts that are going to be washed.