-

×

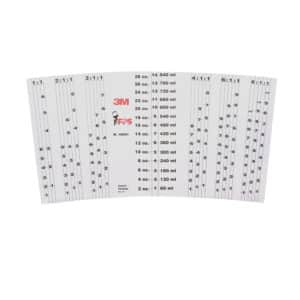

3M 16091, PPS Mix Ratio Inserts, Large (28 fl oz), 7000028411

100 × $65.88

3M 16091, PPS Mix Ratio Inserts, Large (28 fl oz), 7000028411

100 × $65.88 -

×

Standard Abrasives 706317, A/O Straight Cartridge Roll, 1/4 in x 1 in x 1/8 in 100, 7100080010

100 × $0.35

Standard Abrasives 706317, A/O Straight Cartridge Roll, 1/4 in x 1 in x 1/8 in 100, 7100080010

100 × $0.35 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72 -

×

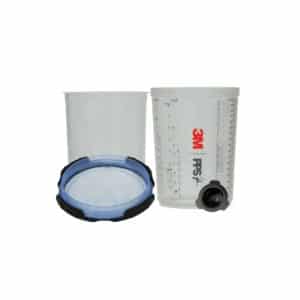

3M 26325, PPS Series 2.0 Spray Cup System Kit, Large (28 fl oz, 850

mL), 125 Micron Filter, 7100134637

1 × $151.19

3M 26325, PPS Series 2.0 Spray Cup System Kit, Large (28 fl oz, 850

mL), 125 Micron Filter, 7100134637

1 × $151.19 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $17.15 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

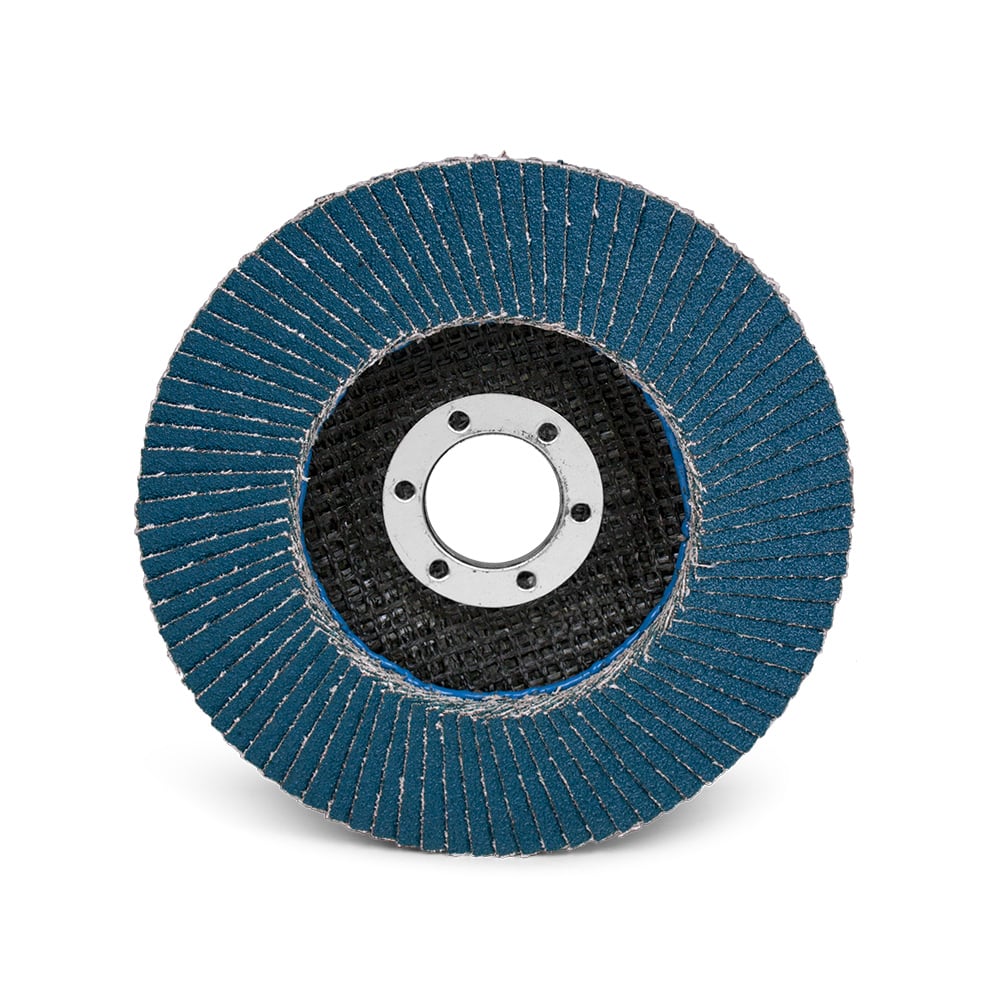

3M 55379, Flap Disc 566A, 60, T27 Quick Change, 4-1/2 in 5/8″-11, Giant, 7010327377, 10 per case

$0.00

Discontinued, Suggested Replacement – 3M 7010327061

3M Flap Disc 566A provides a versatile one-disc system for metal fabrication applications where more durability is needed for medium-weight grinding, small weld removal, finishing, and surface preparation. Run on a right angle grinder, this disc is a one-step alternative to bonded wheels and fiber discs.